Volumetric greasing system on mechanical joints MACONPLEX BA3222

Volumetric greasing on mechanical joints.

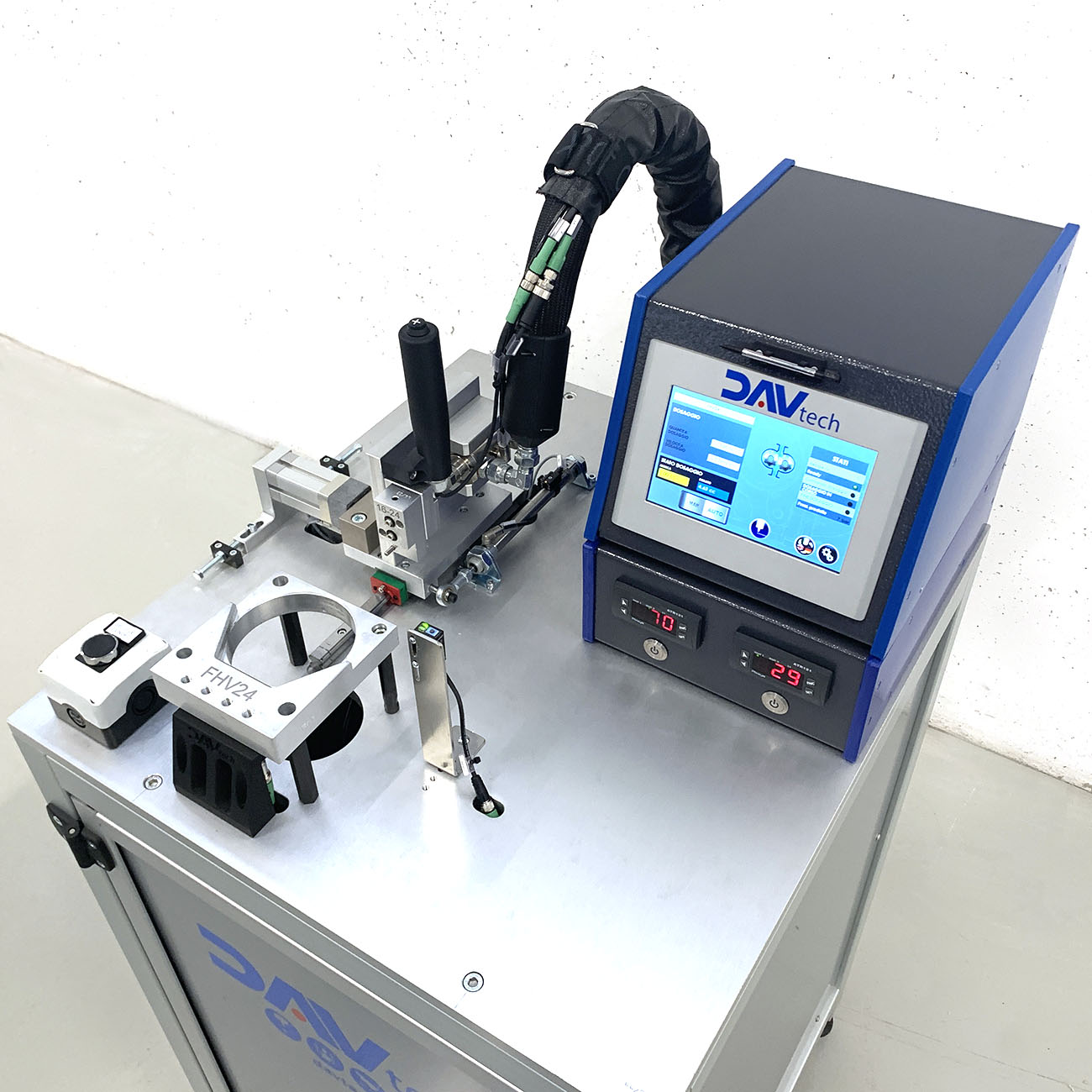

Compact and ergonomic volumetric greasing station for volumetric greasing of high-pressure mechanical joints.

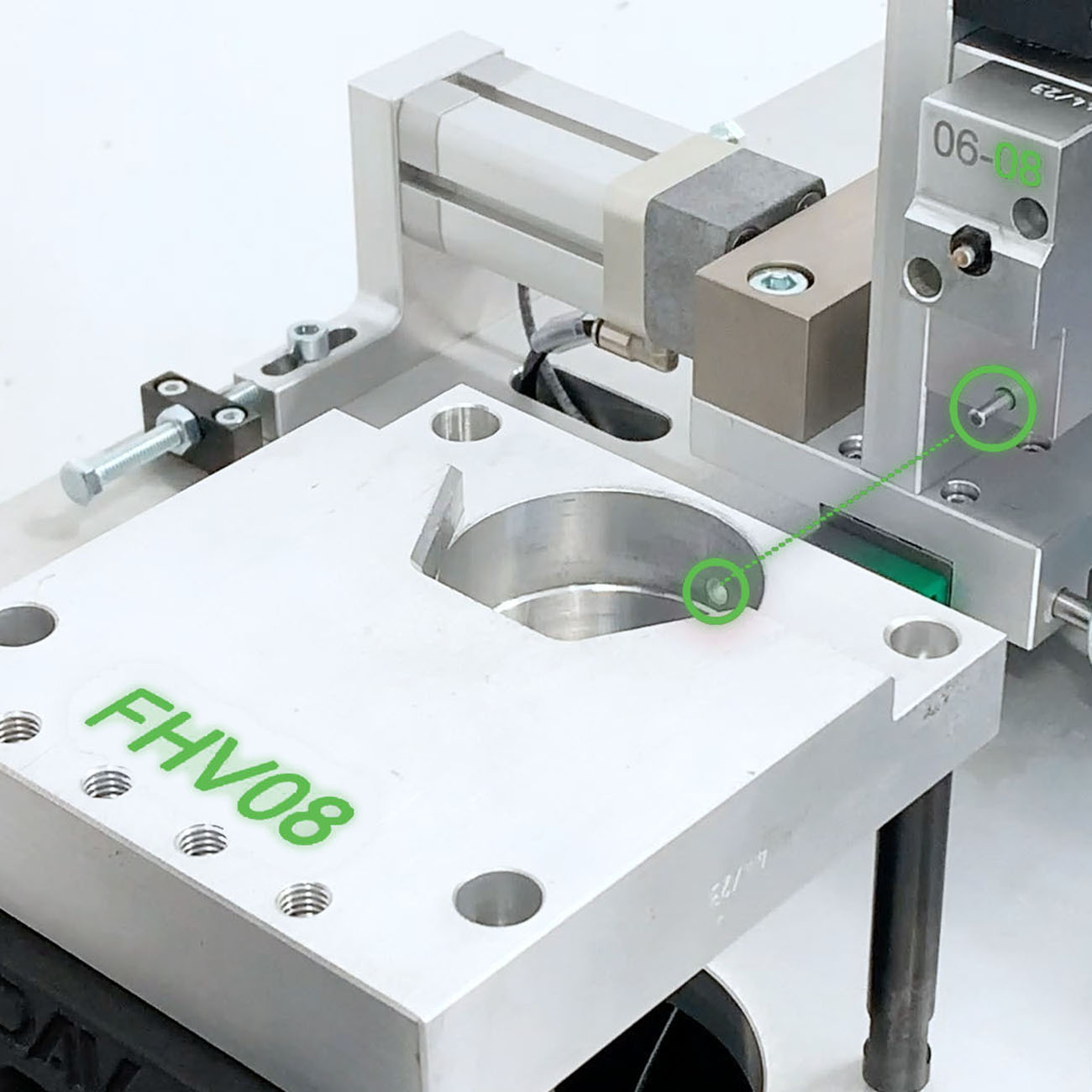

Equipped with customized fixtures coupled with special nozzles, with automatic recognition and selection of the dedicated filling program.

Thanks to the Poka Yoke logic, it guarantees the control of the correct setup.

Characteristics

• Grease heating system for easy filling inside the component

• GP Series Volumetric Gear Pump

• Component presence sensors and correct tooling verification

• Digital controller for easy storage and management of dispensing programs.

CASE STUDY

Volumetric Greasing Station for Mechanical Joints

The customer required a compact and ergonomic solution for volumetric greasing of high-pressure mechanical joints. The goal was to improve the efficiency of the greasing process by ensuring precise control of filling and ensuring that each component was treated correctly and uniformly.

01

Solution Provided

To meet these needs, we have designed a volumetric greasing station with the following features:

Grease Heating System

Integrated Heating

The station is equipped with a grease heating system to facilitate filling inside the mechanical joints, reducing the viscosity of the grease and improving fluidity during the process.

Volumetric Pump and Specialized Nozzles

GP volumetric Pump

Uses a GP series gear pump, ensuring precise and reliable grease dispensing.

Specialized Nozzles

The station is equipped with customized nozzles that perfectly match the mechanical joints, optimizing the greasing process.

Custom Fixtures and Poka Yoke Logic

Customized Fixtures

Custom-designed, the fixtures guarantee perfect compatibility with mechanical joints and facilitate easy alignment during the greasing operation.

Poka Yoke Logic

Implemented to ensure correct tooling and prevent errors during the greasing process, improving filling quality and consistency.

Advanced Control and Management

Presence and Verification Sensors

Advanced sensors monitor the presence of the component and verify the correct tooling, ensuring that every operation is carried out without problems.

Digital Controller

Allows easy storage and management of dispensing programs, facilitating the automatic selection of the dedicated filling program for each type of joint.

02

Results and Benefits

The volumetric greasing station provided significantly improved the efficiency of the greasing process for high-pressure mechanical joints. The integration of the grease heating system and specialized nozzles optimized grease fluidity and dispensing accuracy. Poka Yoke logic and advanced sensors ensured proper tooling and reduced errors, while the digital controller simplified the management of dispensing programs.

In summary, the proposed solution offered an ergonomic and highly efficient greasing station, meeting the customer’s needs with a system that guarantees precision, reliability and ease of use.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!