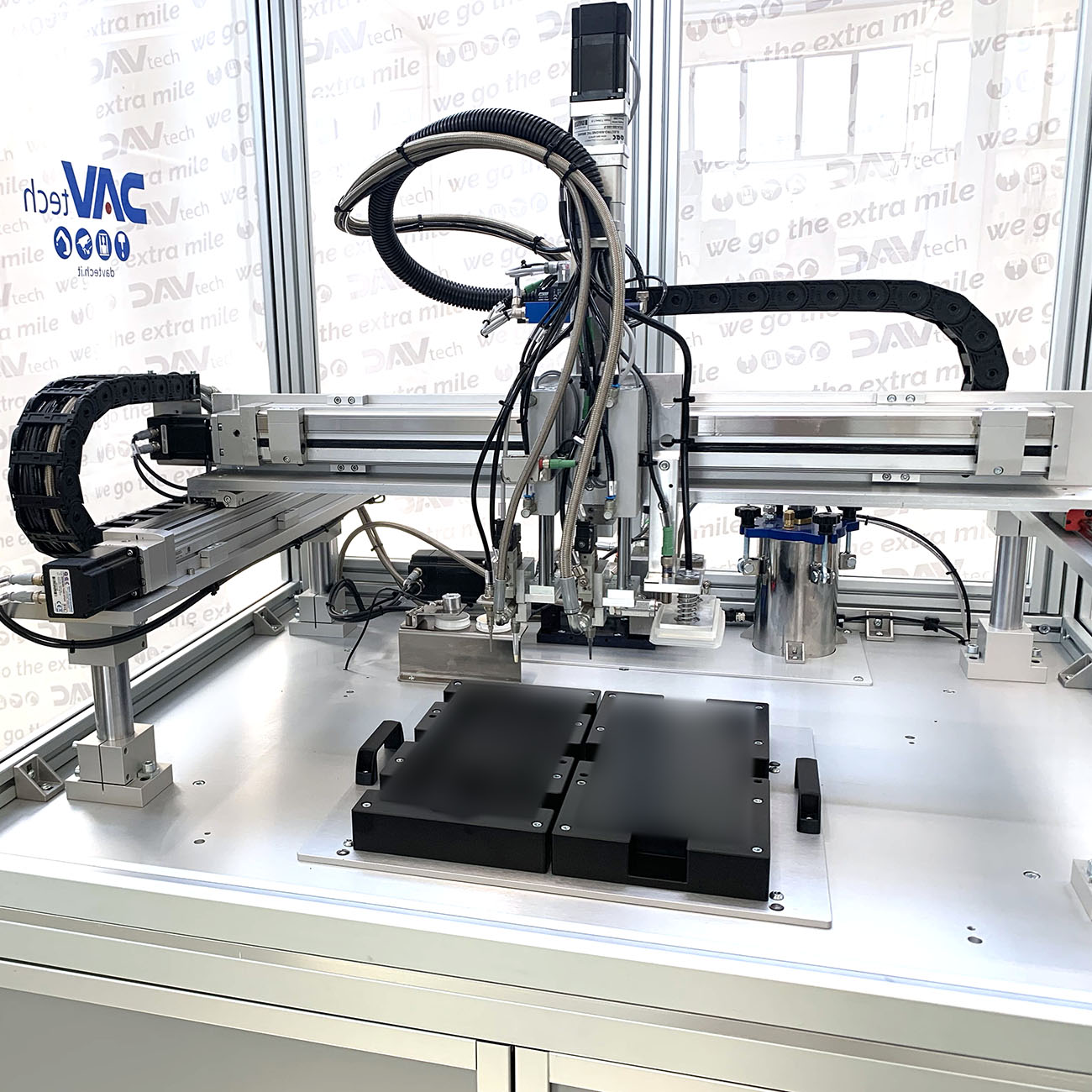

TEROSON MS 939 Primer & Sealing Dispensing System

Robotic cell for primer and sealant dispensing for mounting touch screen displays on frames. Volumetric dispensing, integrated into an interpolated handling system, with complete real-time control and archiving of process parameters.

Customized fixture with Poka Yoke logic.

Characteristics

• Compact layout with interpolated gantry handling system

• Type recognition and workpiece positioning system with automatic program selection

• Exit from the rest area, nozzle purging and cleaning with air knife and brushes

• Volumetric sealant dispensing using DA 400 needle valves.

• Dispensing managed by servo-controlled GP volumetric pump

• Automated system with suction cup for component assembly.

• Volumetric dispensing, not conditioned by sealant temperature and pressure

• Laser system for dimensional measurement and continuity of the bead

• Complete process management via panel PC.

CASE STUDY

Robotic Cell for Primer and Sealant Dispensing in Touch Screen Assembly

The customer needed a robotic solution for the dispensing of primer and sealant in the assembly of touch screens onto frames. The request included the need for precise dispensing control, an interpolated handling system to optimize placement, and complete, real-time management of process parameters. Additionally, a nozzle cleaning system and a compact layout for easy integration into the production line were required.

01

Provided Solution

We designed and implemented an advanced robotic cell with the following features:

Compact Layout with Interpolated Portal Handling System

Interpolated Movement

The system features a compact layout and an interpolated portal handling system, ensuring smooth and precise movement of parts during the dispensing process.

Recognition and Positioning System

Automatic Program Selection

The system automatically recognizes the type and position of the part, selecting the appropriate dispensing program. This automated process improves efficiency and reduces the risk of errors.

Nozzle Cleaning and Maintenance

Purge and Cleaning

After the dispensing phase, the system includes an automated nozzle purge and cleaning procedure with an air knife and brushes, ensuring regular maintenance and reducing downtime.

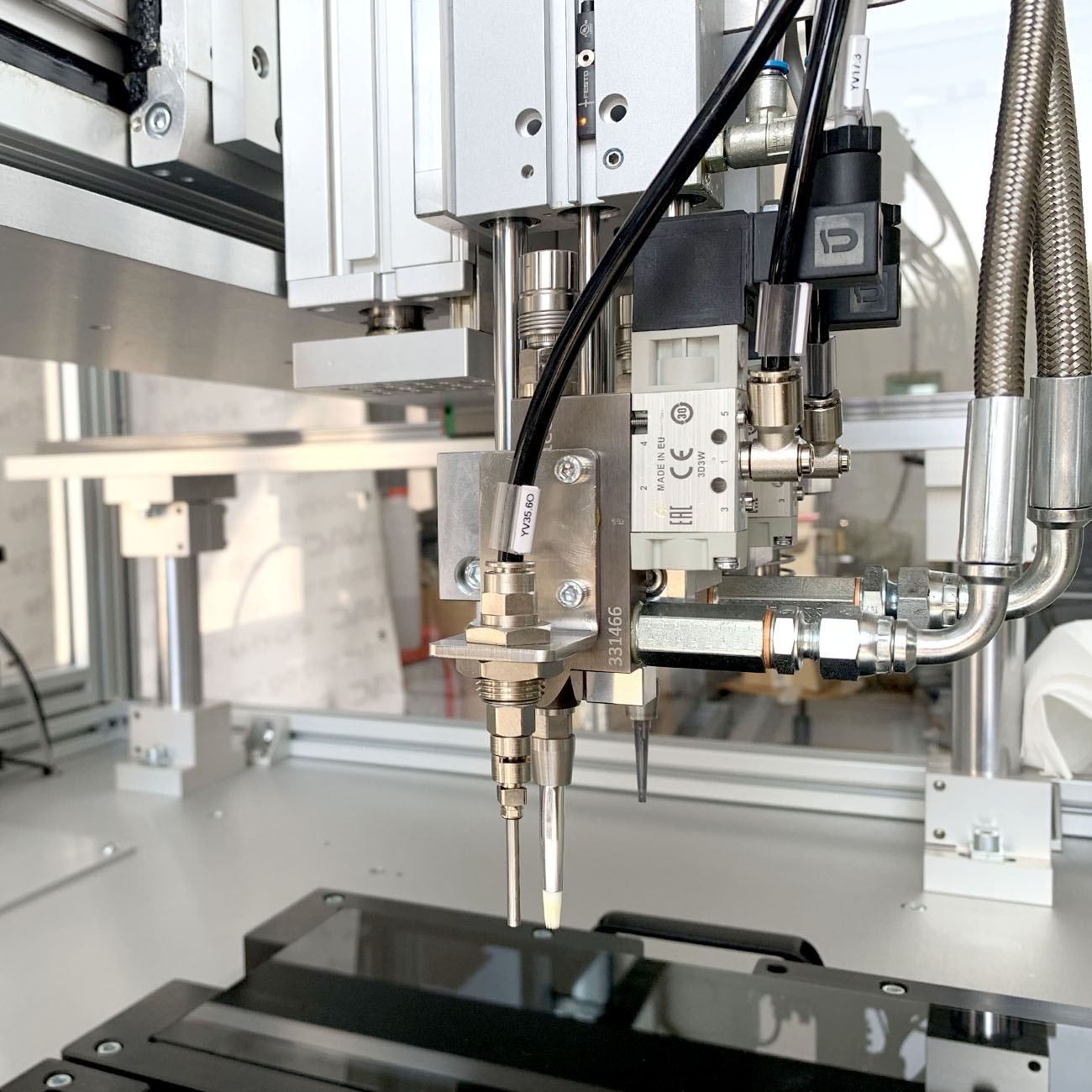

Volumetric Sealant Dispensing

DA 400 Needle Valves

The sealant dispensing is performed using DA 400 needle valves, ensuring precise and uniform application of the sealant.

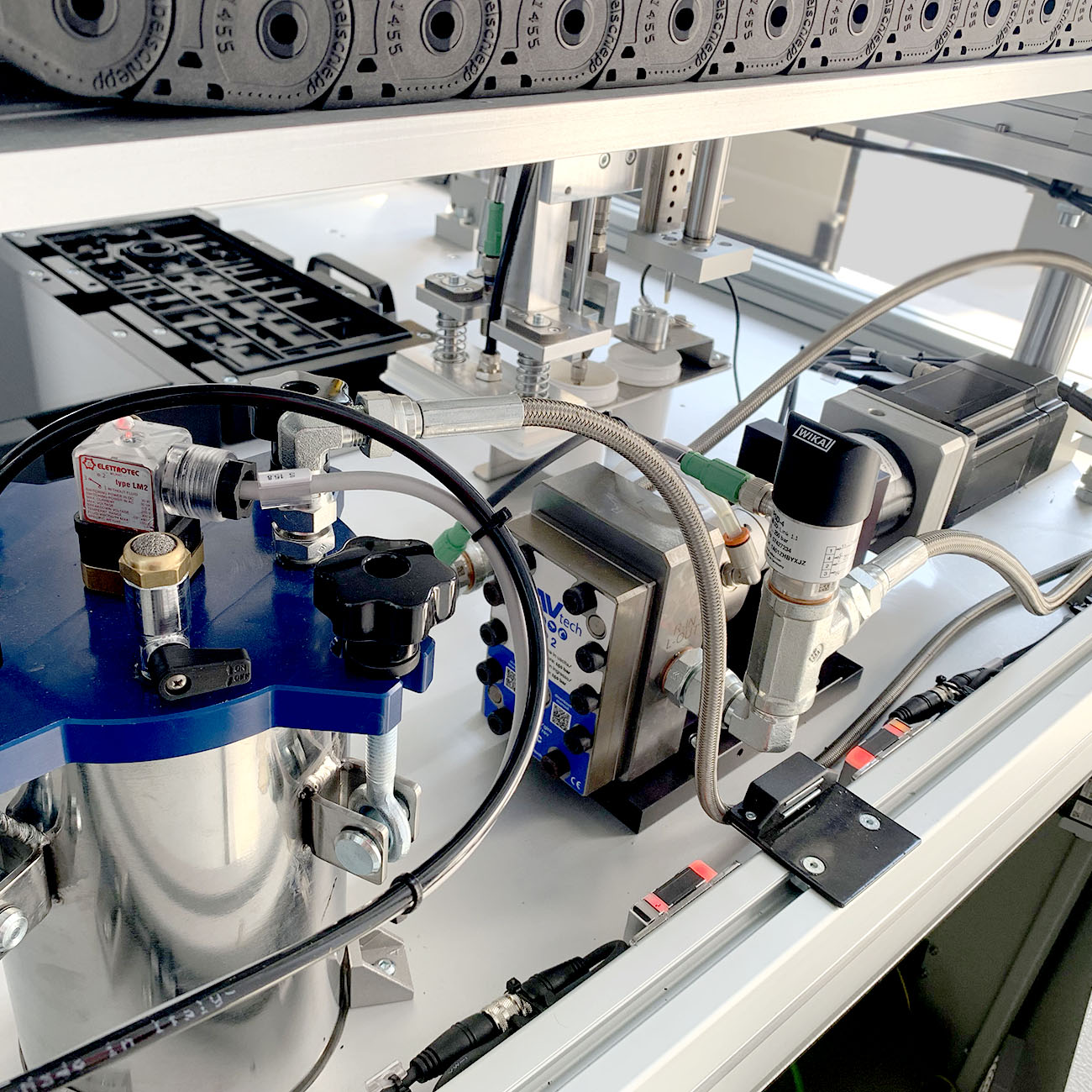

Servo-controlled GP Volumetric Pump

Dispensing is managed by a servo-controlled GP volumetric pump, providing accurate control of the amount of sealant applied.

Component Assembly

Automated Vacuum System

An automated vacuum system is used for component assembly, improving the efficiency and precision of the assembly process.

Control and Measurement

Laser System

The system is equipped with a laser system for dimensional measurement and to ensure the continuity of the sealant bead, ensuring the quality and precision of the final result.

Complete Process Management

Panel PC

The process is fully managed via a panel PC, providing real-time visibility of process parameters and enabling data storage and traceability.

Customized Fixture with Poka Yoke Logic

Poka Yoke Logic

The fixture is designed with Poka Yoke logic to ensure correct positioning and minimize the risk of human errors.

02

Results and Benefits

The provided system brought significant improvements to the touch screen assembly process:

- Precision and Efficiency: The combination of interpolated movement, needle valves, and the servo-controlled pump ensured precise dispensing and smooth handling, optimizing production efficiency.

- Cleaning and Maintenance: The automated purge and cleaning system reduced the need for manual intervention, keeping the nozzle in optimal condition and minimizing downtime.

- Quality Control: The laser system ensured the quality of the sealant bead and provided detailed data for process traceability.

- Flexibility and Traceability: Management via the panel PC and Poka Yoke logic improved traceability and process correctness, making the system adaptable to different product variants.

This robotic cell provided a complete and integrated solution for primer and sealant dispensing, meeting the customer’s specific needs and significantly improving the quality and efficiency of production.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!