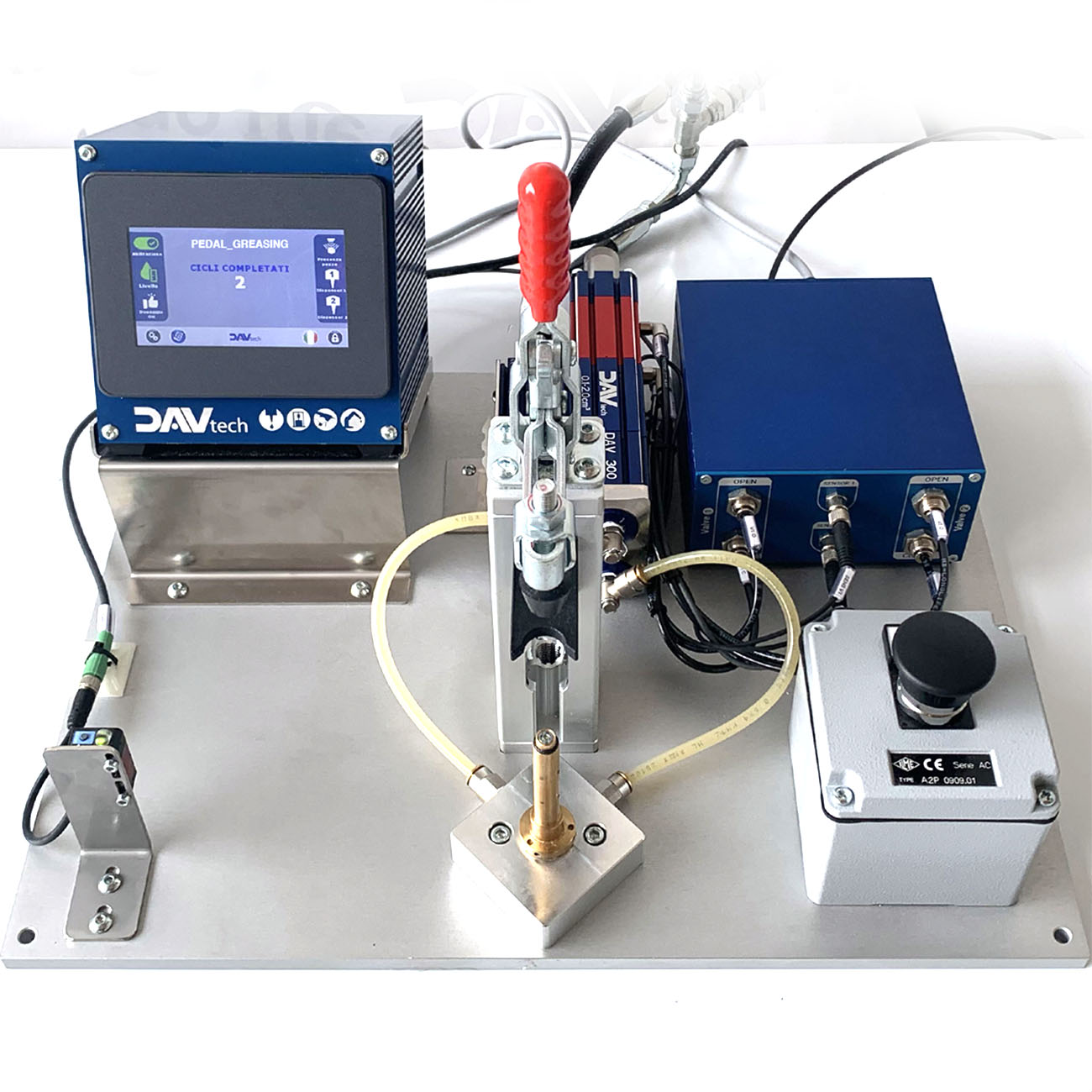

SKF LGWA 2 greasing system

Tabletop system for volumetric Grease dispensing with integrated process controls.

Characteristics

• 2 DAV 300 volumetric valves

• Component presence sensor

• Fluid level sensor

• Smart controller 2000 DA

• Pneumatic expansion for the operation of dispensing valves and correct dispense objectification

• Multilingual panel management

• Individual valve metering sensor

• Cycle Completed Count

• Customized equipped fixture

CASE STUDY

Optimizing Grease Dispensing with an Advanced Tabletop System

The customer, a leading manufacturer of mechanical components, needed a highly precise tabletop system for volumetric dispensing of grease. The system had to be able to ensure accurate control of the greasing process, integrating sensors and controls to manage various dispensing parameters and monitor fluid flow. The goal was to optimize dispensing accuracy, reduce waste, and improve operational efficiency.

01

Our solution

To meet these needs, we have designed and implemented an advanced tabletop system for volumetric Grease dispensing, complete with integrated process controls.

Main Components

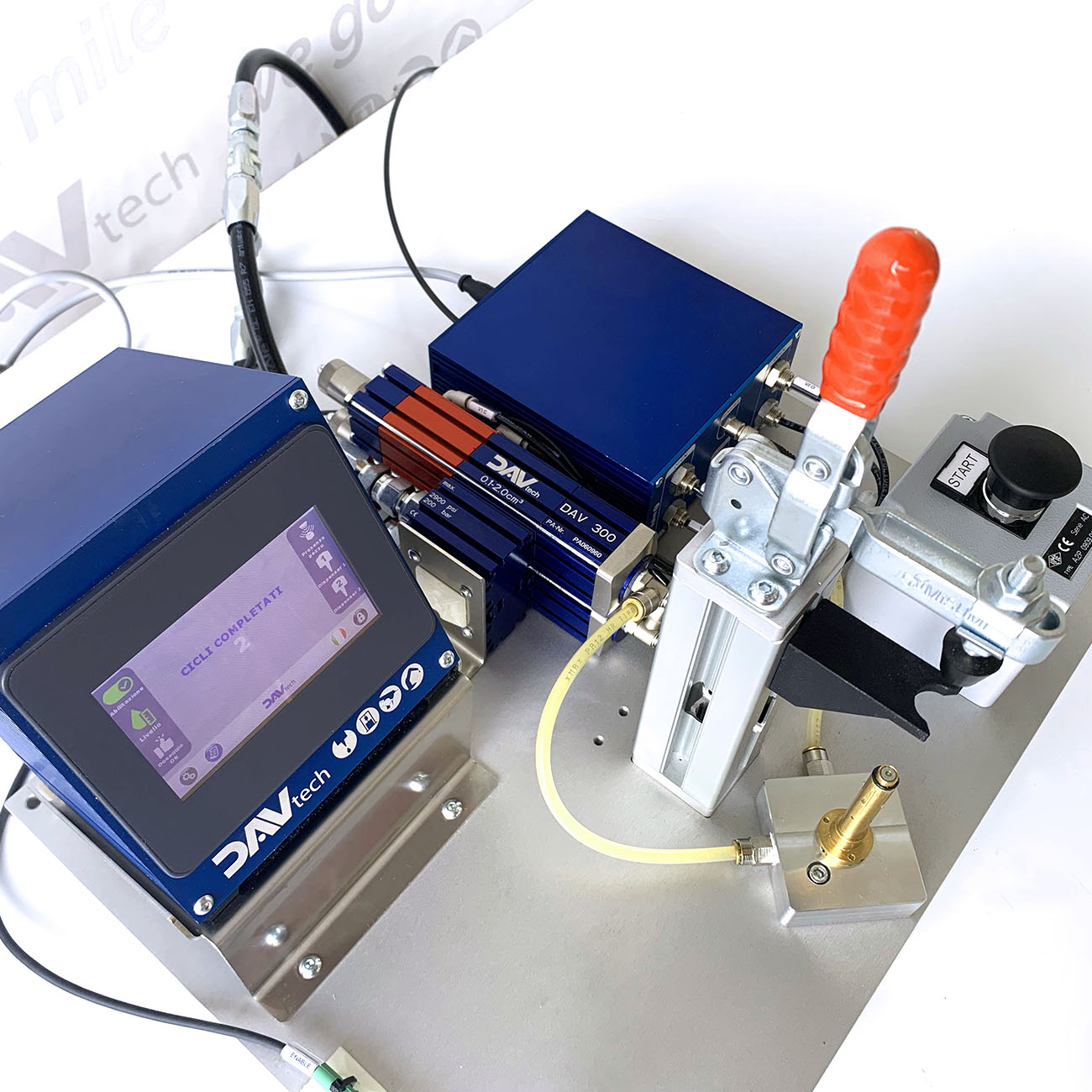

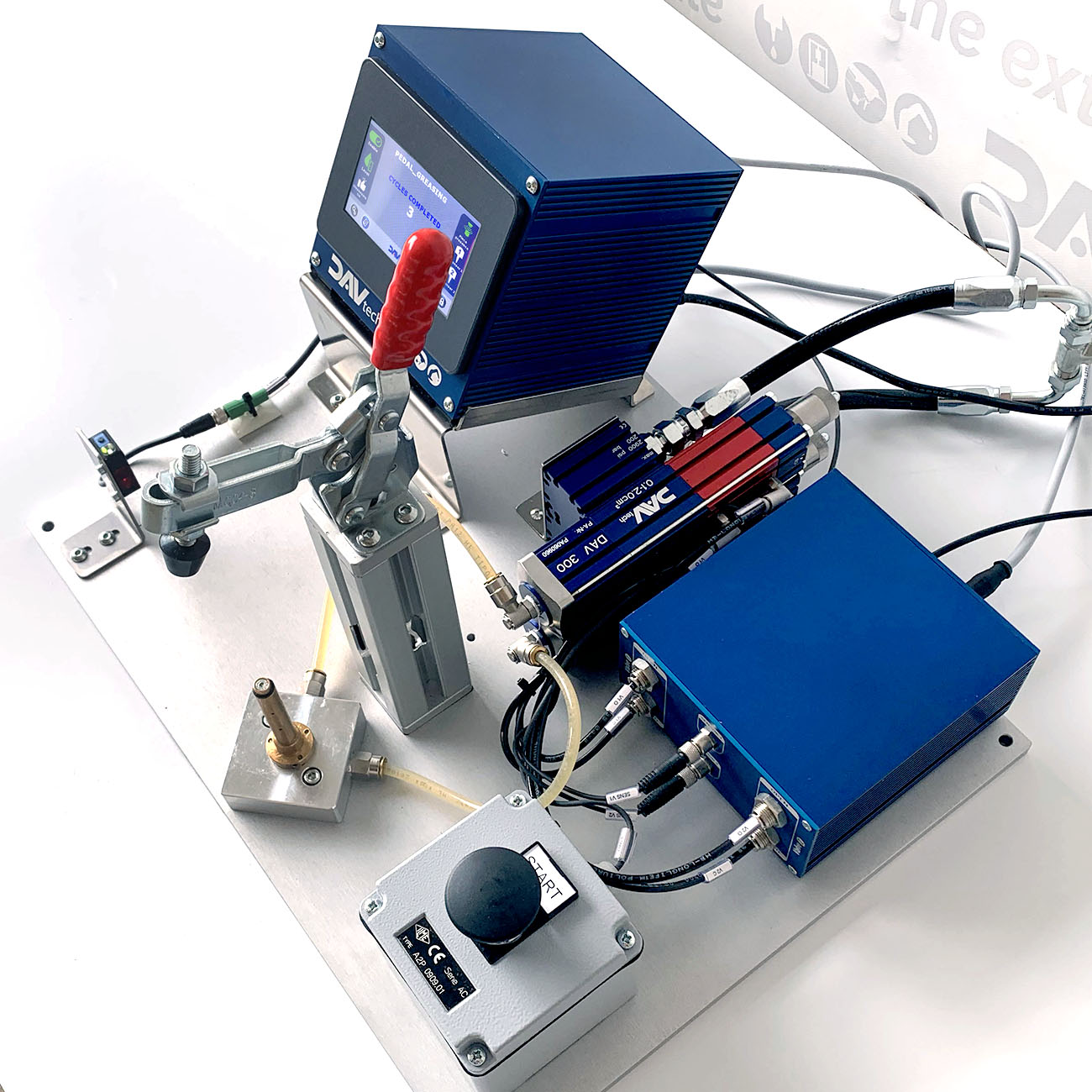

DAV 300 Volumetric Valves

Two high-precision volumetric valves have been installed to manage the grease dispensing with extreme accuracy.

Advanced Sensors

Component presence sensors and fluid level sensors have been integrated to ensure proper system operation and prevent malfunctions.

Smart Controller 2000 DA

The heart of the system is an intelligent controller that manages all dispensing parameters and controls the process in real time.

Pneumatic Expansion

The pneumatic expansion has been designed to operate the dispensing valves and ensure correct dispensing, improving the reliability of the system.

Advanced Features

Multilingual management

The control panel is equipped with a multilingual interface for intuitive and personalized management of the system.

Dispensing Sensors

Each valve is equipped with a specific dispensing sensor to monitor and regulate the flow of Grease with precision.

Cycle Counting

The system includes a completed cycle counting function to track and verify the performance of the dispensing.

Customization and Integration

Customized Fixture

A customized fixture has been designed, equipped to perfectly adapt to the specific needs of the customer, ensuring trouble-free installation and operation.

02

Results and Benefits

The implemented tabletop system has significantly improved the accuracy of grease dispensing, reducing waste and optimizing production times. Advanced sensors and integrated control ensured continuous monitoring and precise process management, while the custom fixture facilitated system integration with existing production lines. The multilingual panel and advanced features have made the system easy to use and adaptable to future needs.

In conclusion, our solution has enabled the customer to achieve high standards of quality and operational efficiency, cementing our reputation as a reliable partner for advanced dispensing systems.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!