PERMABOND ET5401 epoxy resin dispensing and mixing system

System for dispensing and mixing epoxy resin on filter bodies.

Through the DAV Tech components it is possible to manage the flow rate, the quantity dispensed, the rotation of the tool and the out of space of the dispenser.

Characteristics

• DA 2K valve

• Customized interchangeable self-locking fixture

• Component presence sensors

• GP Controller

• GP volumetric gear pumps

• 2 PP50 Pressure Plate Pumps

CASE STUDY

System for Dispensing and Mixing Epoxy Resin on Filter Bodies

A company operating in the filtration sector required an advanced system for the dispensing and mixing of epoxy resin applied to filter bodies. The requested solution had to ensure precise control over the flow rate and quantity of resin, as well as accurate management of tool rotation and dispenser positioning. The company was looking for a solution that could improve the efficiency and quality of the production process, integrating advanced components and optimal operation management.

01

Provided Solution

To meet the customer’s needs, we designed a complete system for dispensing and mixing epoxy resin, using high-quality components supplied by DAV Tech. The solution was designed to ensure precision, flexibility, and ease of use.

Main Components

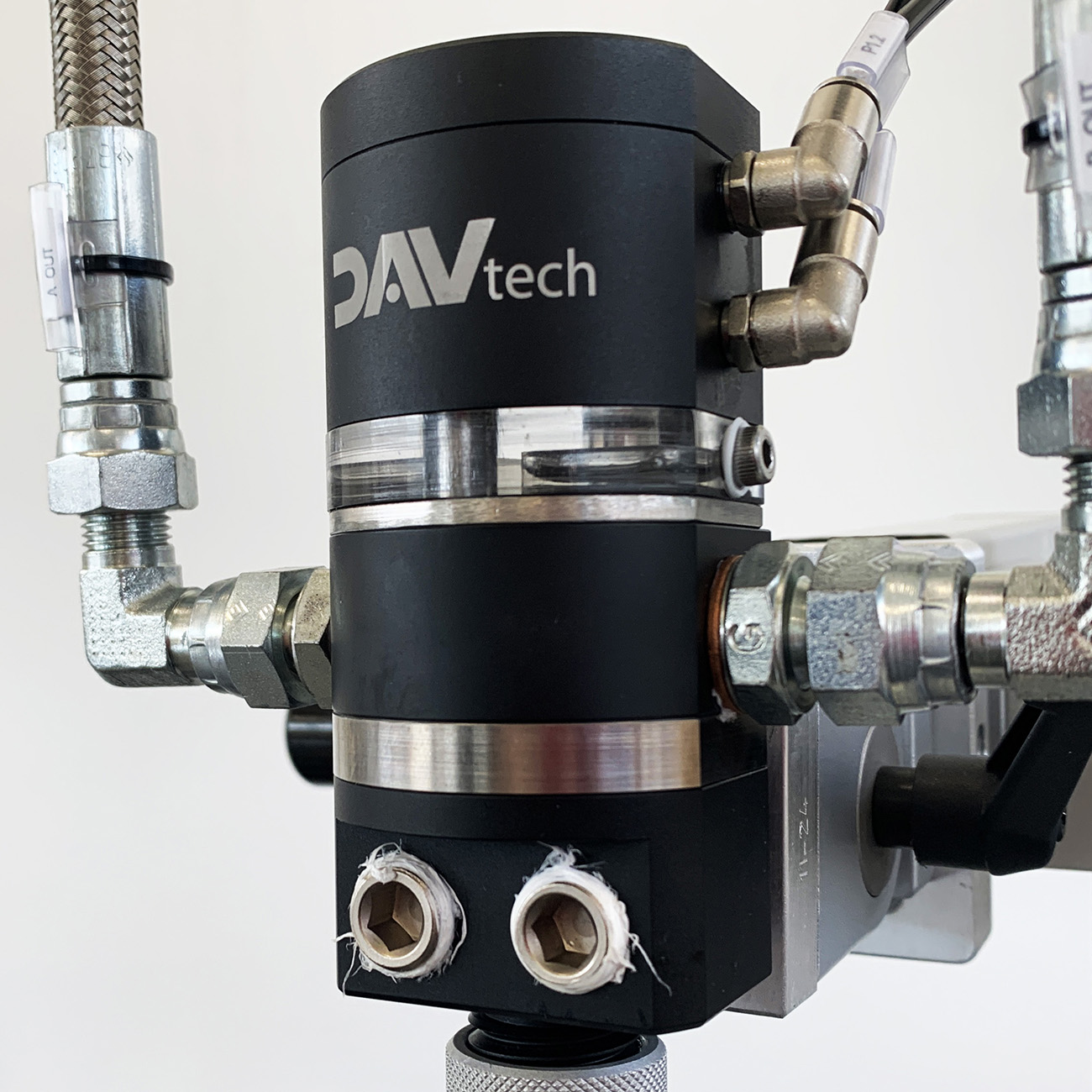

DA 2K Valve

This valve was chosen for its ability to handle 2K fluids, ensuring precise mixing of the epoxy resin during the dispensing process.

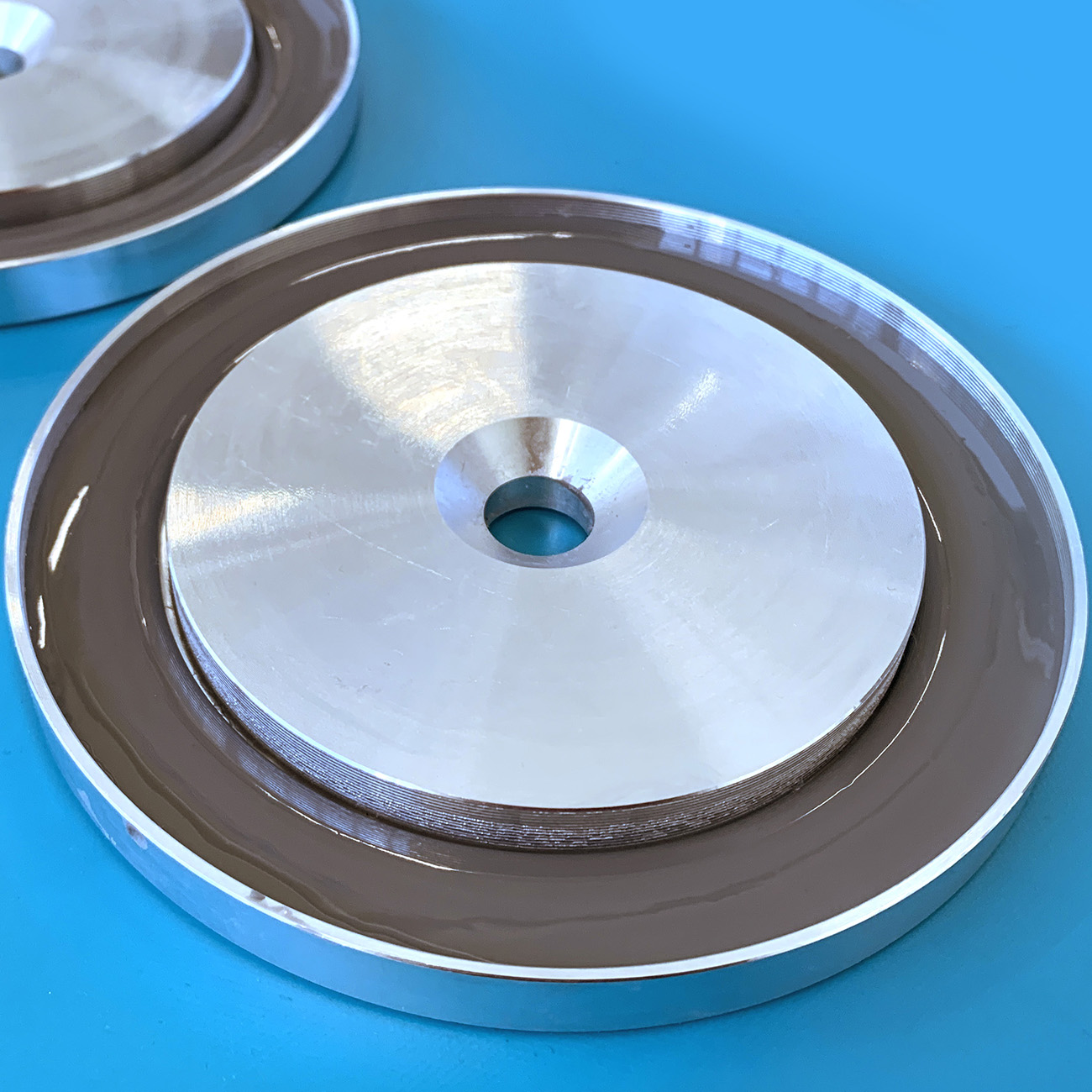

Custom Auto-locking Interchangeable Fixture

The custom fixture features an auto-locking and interchangeable system, designed to hold the filter bodies in place during dispensing and facilitate quick changes between different applications.

Component Presence Sensors

The integrated sensors ensure that the filter bodies are correctly positioned before the process begins, improving the quality and accuracy of the dispensing.

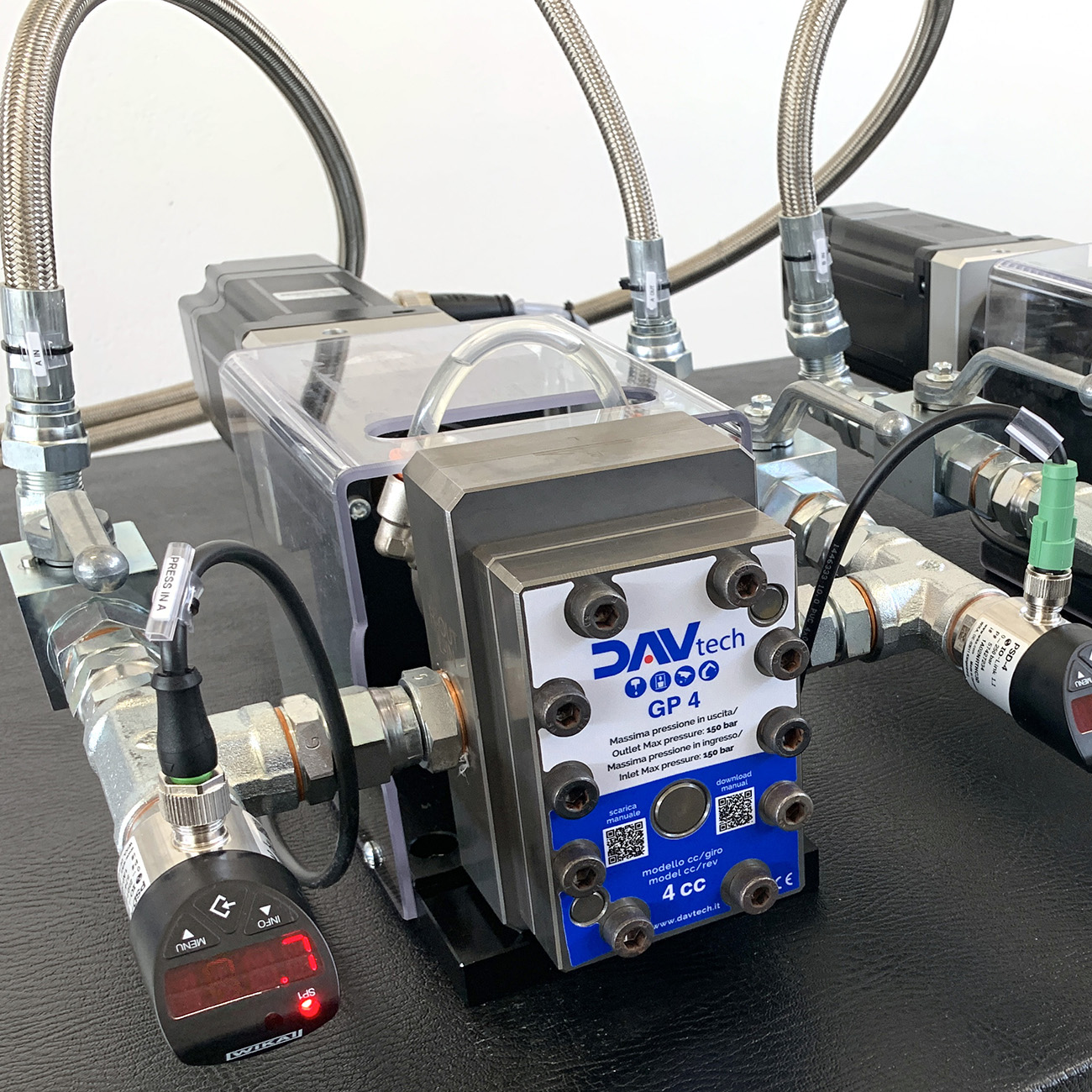

GP Controller

The GP controller manages all system parameters, including the flow rate and quantity of resin dispensed, and coordinates tool rotation for optimal mixing.

GP Gear Pumps

The GP gear pumps are used to ensure precise and consistent dispensing of the epoxy resin.

PP50 Plunger Pumps

These pumps are integrated to manage the pressure and flow of resin, ensuring uniform and controlled distribution during the process.

Advanced Features

Flow Rate and Quantity Management

The system allows for precise adjustment of the flow rate and quantity of dispensed epoxy resin, optimizing performance and the quality of the final product.

Tool Rotation and Dispenser Overhang Management

Tool rotation and dispenser overhang are controlled via the GP controller, improving flexibility and efficiency in the application process.

02

Results and Benefits

The designed system fully met the customer’s needs, providing an advanced solution for dispensing and mixing epoxy resin. The integration of the DA 2K valves, GP gear pumps, and PP50 plunger pumps ensured precise mixing and dispensing. The custom fixture and presence sensors ensured accurate positioning of the filter bodies and optimal process management.

In summary, the provided solution improved the efficiency and quality of the production process, effectively addressing the customer’s specific needs and optimizing the management of epoxy resin.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!