PACTAN 5036 volumetric sealing system

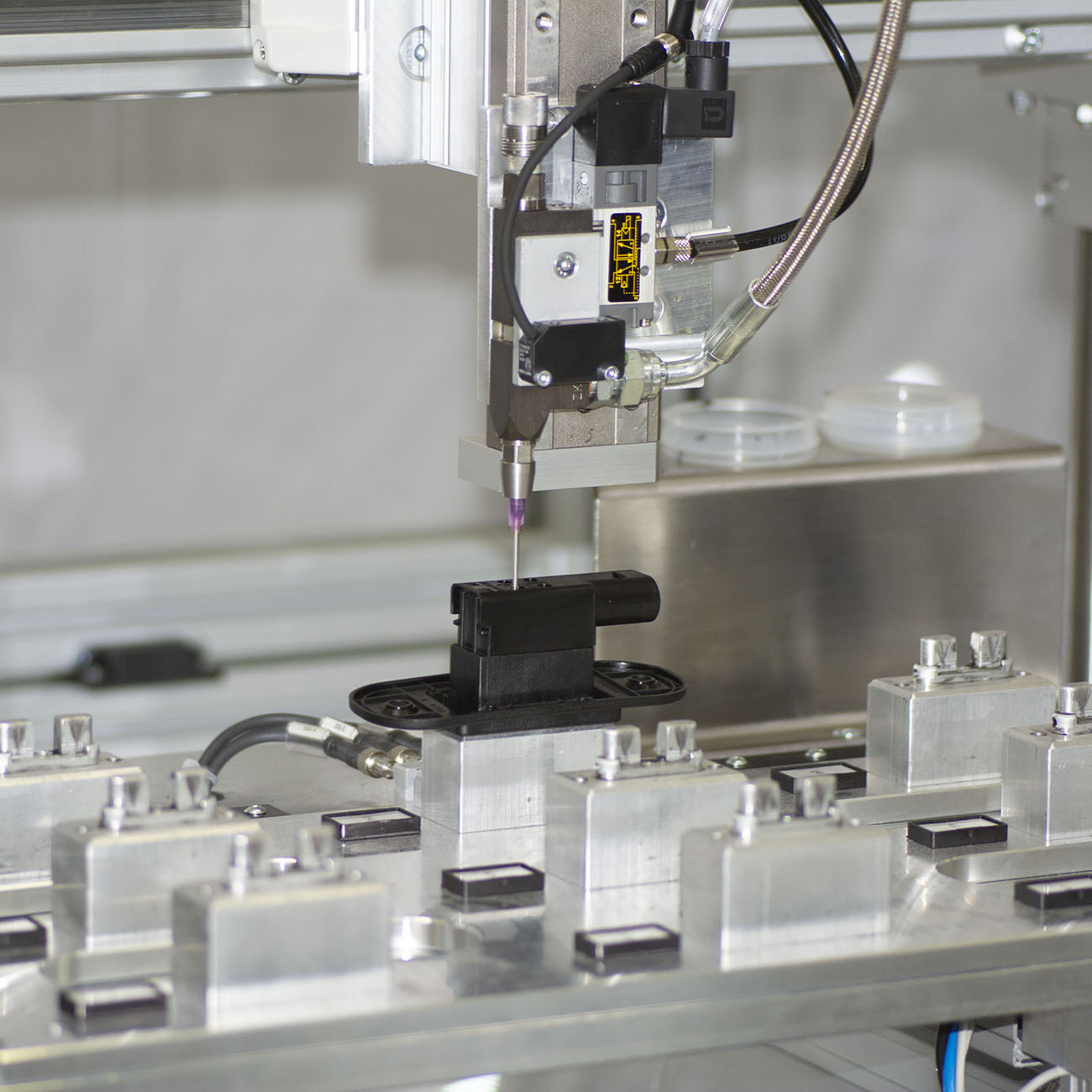

Volumetric dispensing system with 3 interpolated axes for sealing automotive components. Complete with roller conveyor for pallet loading/unloading and scrap box management.

Robotic cell to manage volumetric dispensing of curbs or fillings on connectors, quick loading roller conveyor without effort for the operator, management of the quantity dispensed from the touch screen panel.

Characteristics

• Dispensed quantity control system

• Effortless loading and indexing system for the operator

• Component presence control and objectified rejection of non-dispensed parts

• Multi-pallet system, dispensing of different components in the same process.

CASE STUDY

3-Axis Interpolated Volumetric Dispensing System for Sealing Automotive Components

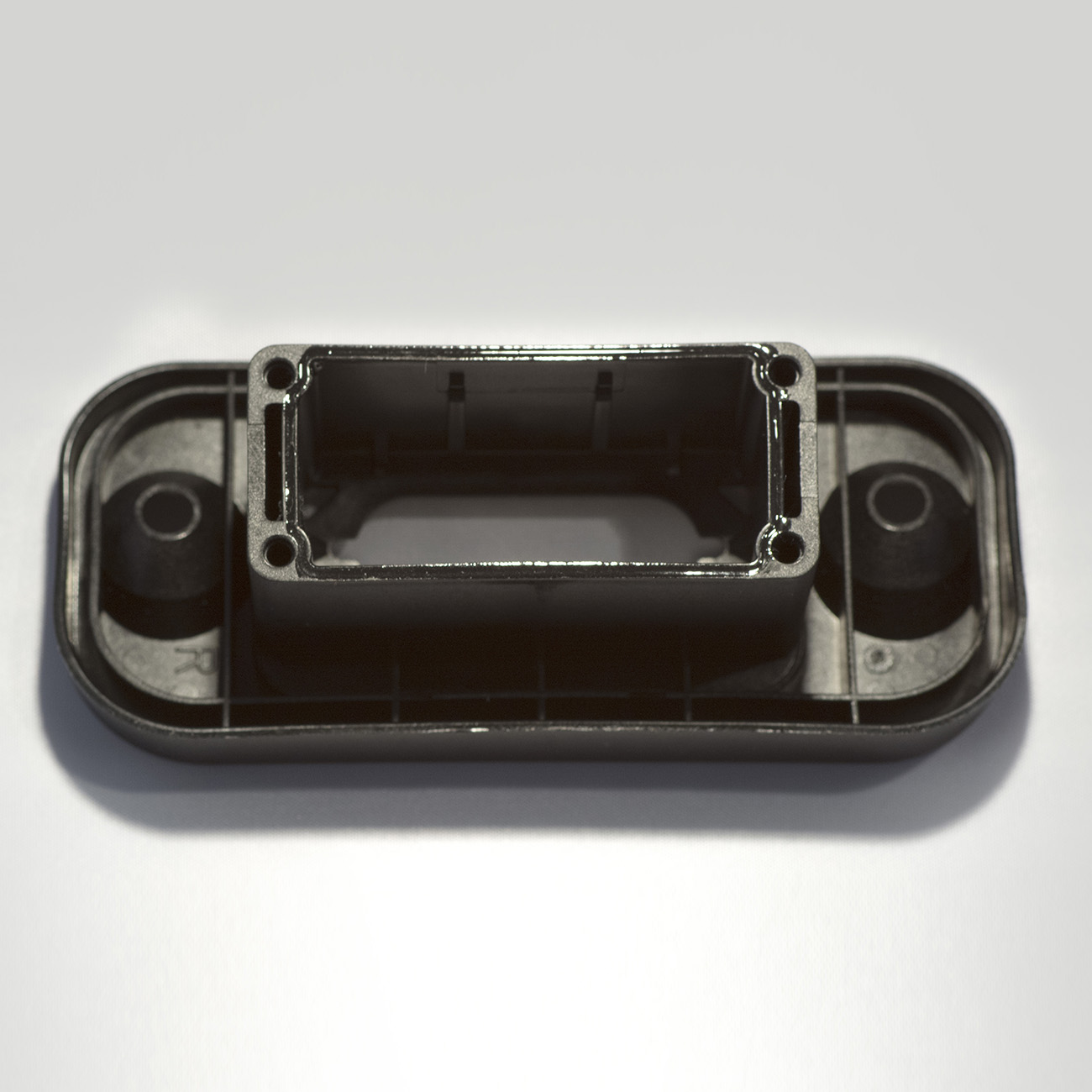

The customer required an advanced system for the volumetric sealing of automotive components, with a particular focus on dispensing sealant for bead applications and filling connectors. It was essential to integrate a roller conveyor for pallet loading and unloading, as well as a scrap box management system, with precise control over the amount dispensed and ease of use for the operator.

01

Provided Solution

We designed a 3-axis interpolated robotic cell, complete with a roller conveyor and scrap box management, with the following features:

3-Axis Interpolated Volumetric Dispensing System

Precise Motion and Dispensing

The system utilizes a 3-axis Cartesian interpolated robot, allowing precise control over the position and amount of sealant dispensed on automotive components such as connectors and beads.

Advanced Management and Control

Dispensed Quantity Control System

The amount of sealant dispensed is managed and monitored through a touch screen panel, enabling the operator to easily configure and adjust dispensing parameters.

Component Presence and Scrap Control

The system includes sensors for component presence detection and the identification of undispensed parts, ensuring process efficiency and reducing waste.

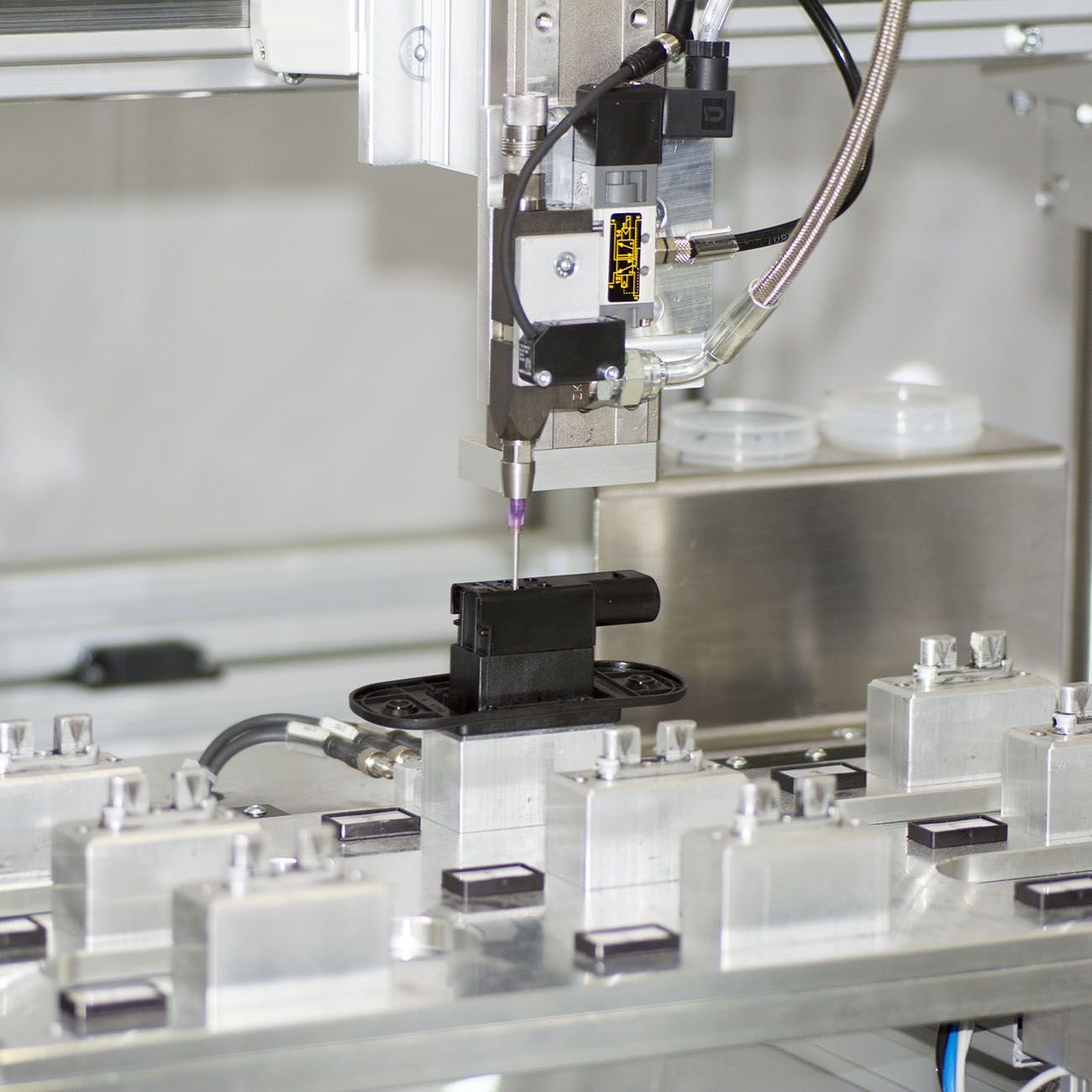

Roller Conveyor and Pallet Loading/Unloading

Quick-Load Roller Conveyor

The integrated roller conveyor facilitates rapid pallet loading and unloading, reducing the operator’s workload and improving process efficiency.

Scrap Box Management

The system is equipped with a scrap box management feature for collecting and handling discarded parts, ensuring optimal material handling.

Multi-Pallet System and Versatility

Dispensing for Various Components

The system is designed to manage dispensing on different types of components in the same process, thanks to its multi-pallet configuration. This increases flexibility and reduces changeover times between different parts.

02

Results and Benefits

The 3-axis interpolated volumetric dispensing system provided numerous benefits to the customer, including:

- Precision and Control: The system ensured precise and controlled dispensing of the sealant, improving the quality of automotive components and reducing the risk of errors.

- Operational Efficiency: The roller conveyor and pallet loading/unloading system simplified operator tasks, increasing efficiency and reducing cycle times.

- Optimal Scrap Management: The scrap box management and detection of undispensed parts contributed to a significant reduction in waste and a more sustainable material handling process.

- Flexibility and Versatility: The ability to dispense various components in the same process increased the system’s flexibility, adapting to the customer’s varying production needs.

This robotic system provided a complete and advanced solution for the volumetric sealing of automotive components, effectively meeting the customer’s needs and significantly improving the productivity and quality of the production process.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!