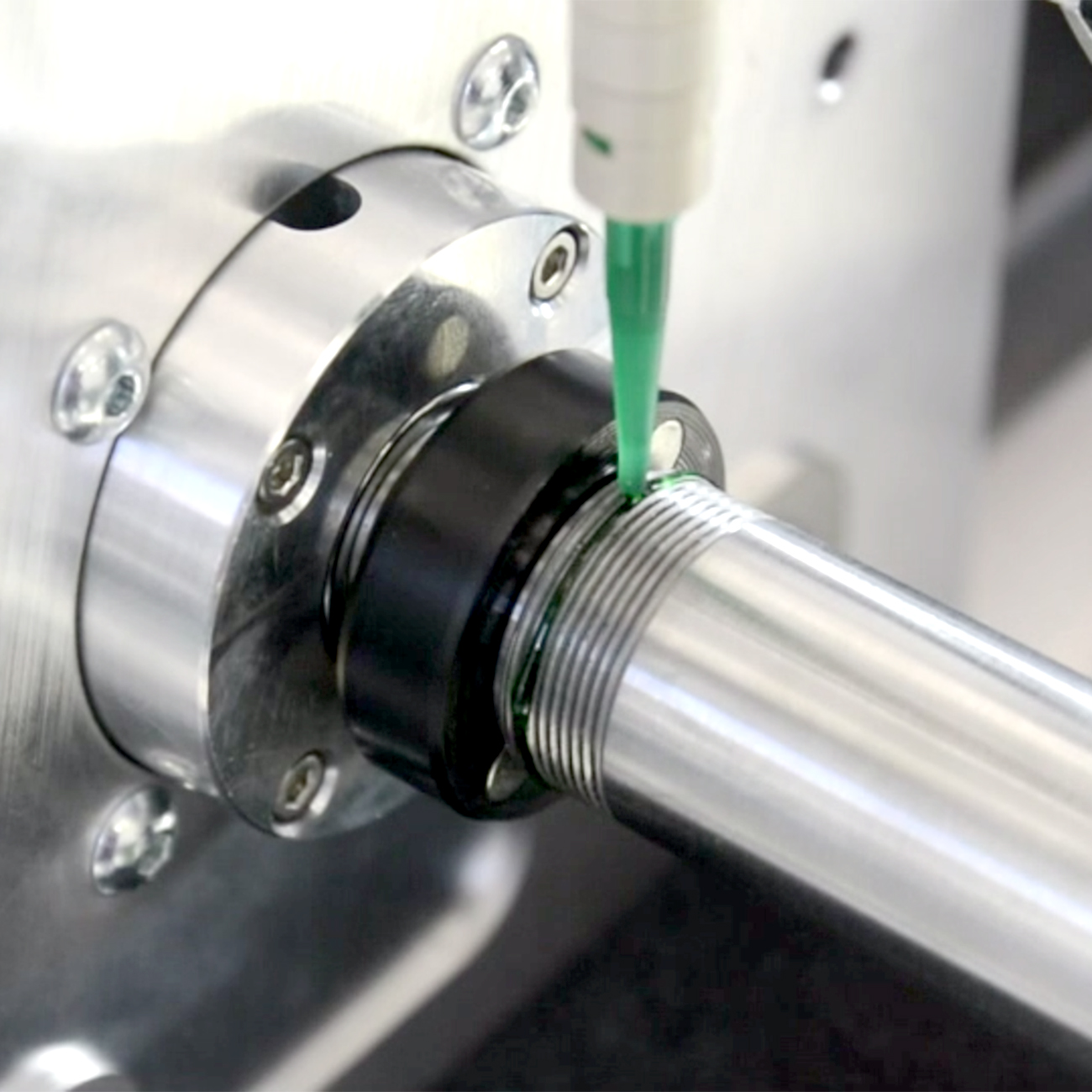

Loctite 648 Anaerobic Glue Dispensing System

Loctite 648 anaerobic glue volumetric dispensing bench on threaded tubes. Management of dispensing parameters (quantity, flow rate, suck back, etc.) via a dedicated controller.

Characteristics

• PCP volumetric pump with PEEK body

• Customized self-locking fixture

• Component presence sensors

• PCP Basic Controller

• PT 2

CASE STUDY

Workstation for Volumetric Dispensing of Loctite 648 Anaerobic Adhesive

A company specializing in the production of mechanical components required a solution for the volumetric dispensing of Loctite 648 anaerobic adhesive onto threaded tubes. The system needed to allow precise management of dispensing parameters, including quantity, flow rate, and a “suck back” mechanism to prevent spills. Additionally, it was essential that the solution be equipped with a custom fixture and a dedicated controller to ensure a uniform and problem-free application.

01

Provided Solution

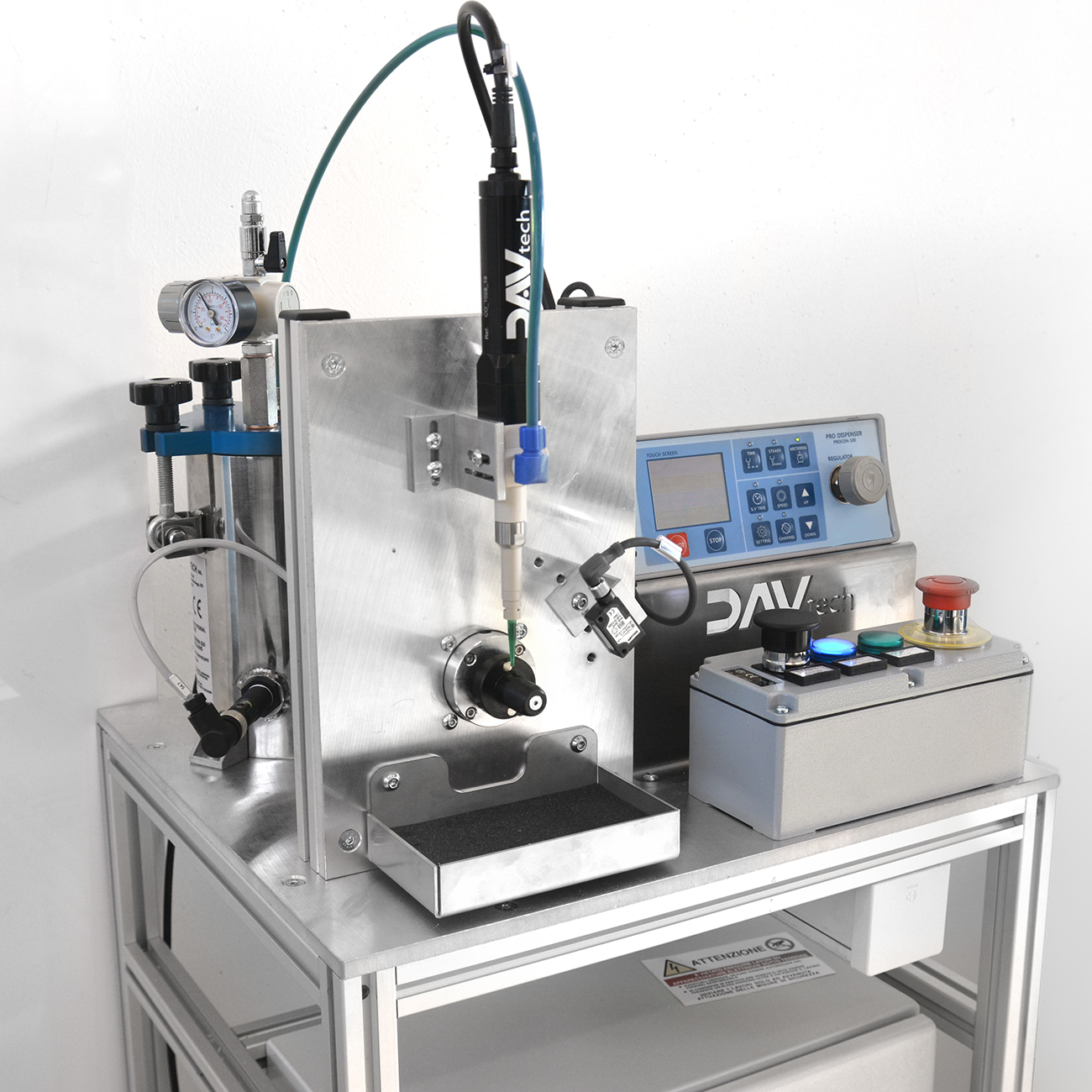

To meet the customer’s needs, we designed and built a custom volumetric dispensing workstation, optimized for the precise management of Loctite 648 anaerobic adhesive. The system was designed to ensure efficiency, precision, and ease of use.

Main Components

PCP Volumetric Pump with PEEK Body

The PCP volumetric pump, made from PEEK, was selected for its chemical resistance and ability to handle viscous fluids like Loctite 648 adhesive, ensuring accurate and reliable dispensing.

Custom Auto-Locking Fixture

The custom fixture was designed to securely hold the threaded tubes in place during the dispensing process, ensuring uniform adhesive application and preventing movement or errors.

Component Presence Sensors

The component presence sensors ensure the threaded tube is properly positioned before dispensing begins, enhancing the quality and accuracy of the application.

PCP Basic Controller

The PCP Basic controller manages all dispensing parameters, including quantity, flow rate, and the “suck back” system. This dedicated controller provides full and precise control over the dispensing process.

Pressurizable PT Tank

The PT 2 pressurizable tank was integrated to manage the adhesive supply, maintaining the proper pressure and improving flow consistency.

Advanced Features

Dispensing Parameter Management

The system allows for detailed adjustment of dispensing parameters via the dedicated controller, ensuring that the quantity and flow rate of the adhesive are optimized for specific applications.

“Suck Back” System

The controller manages a “suck back” system to prevent adhesive spillage after dispensing, improving efficiency and reducing waste.

02

Results and Benefits

The volumetric dispensing workstation designed fully met the customer’s needs, providing an effective and precise solution for dispensing Loctite 648 anaerobic adhesive. The PCP volumetric pump and the auto-locking fixture ensured a uniform and trouble-free application, while the PCP Basic controller allowed for detailed and customized control of the dispensing process. The integration of the pressurizable tank further improved the system’s reliability and consistency.

In summary, the provided solution optimized the dispensing process, enhancing accuracy and reducing waste, effectively addressing the customer’s specific requirements.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!