DowSil 7091 Volumetric Sealing System

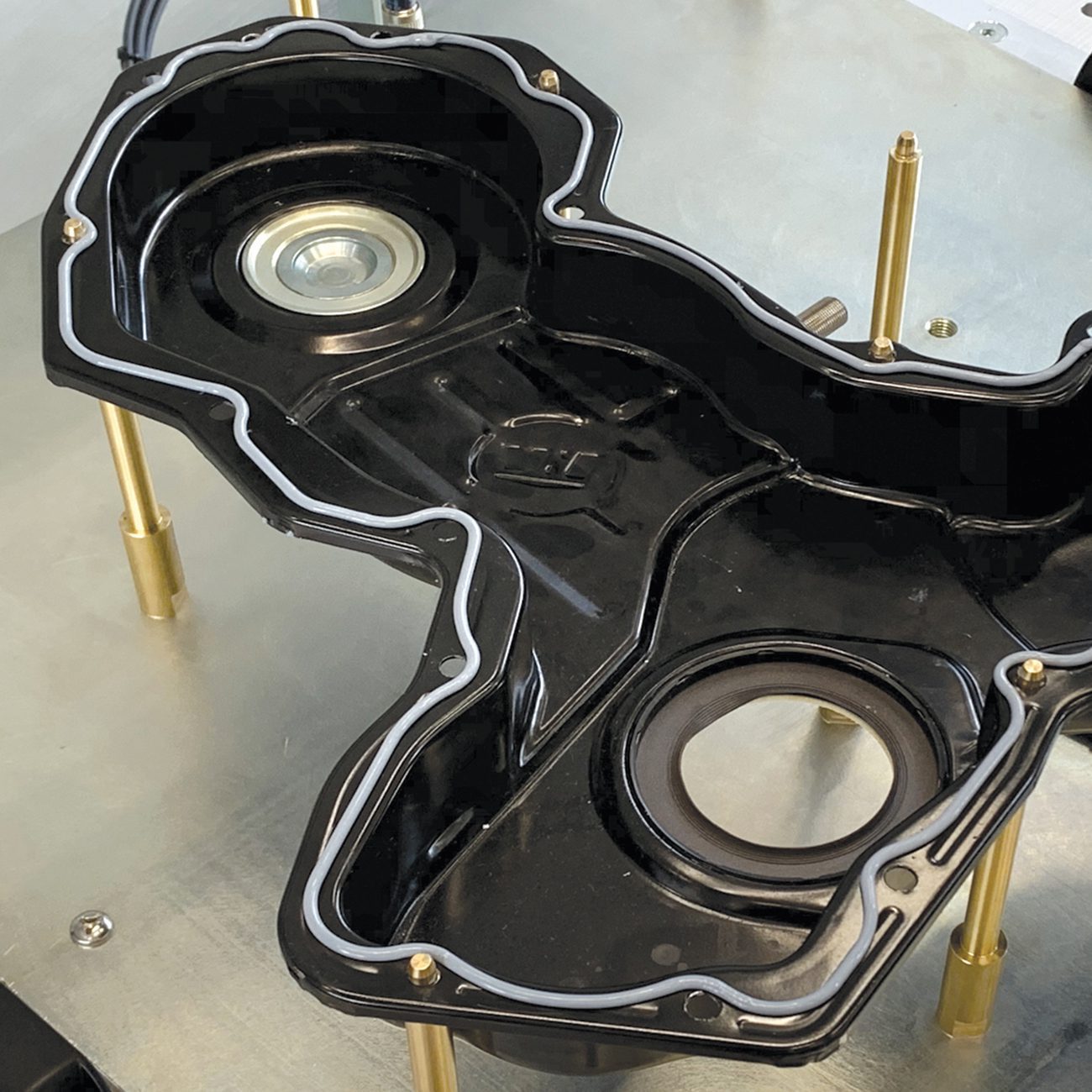

DowSil 7091 robotic cell for dispensing sealant on automotive casing. Volumetric dispensing, integrated into an interpolated handling system, with complete real-time control and archiving of process parameters.

Characteristics

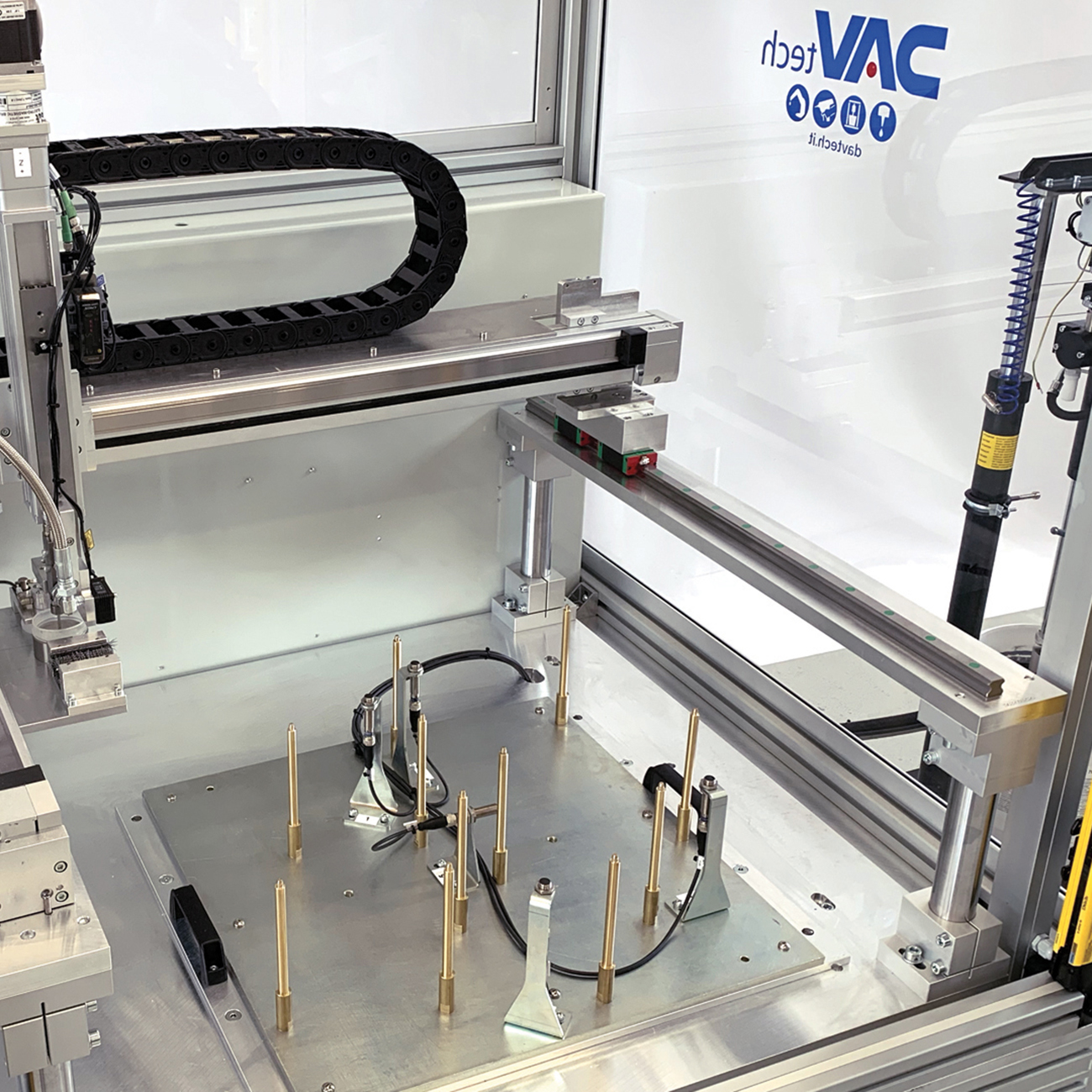

• Compact layout with interpolated gantry handling system

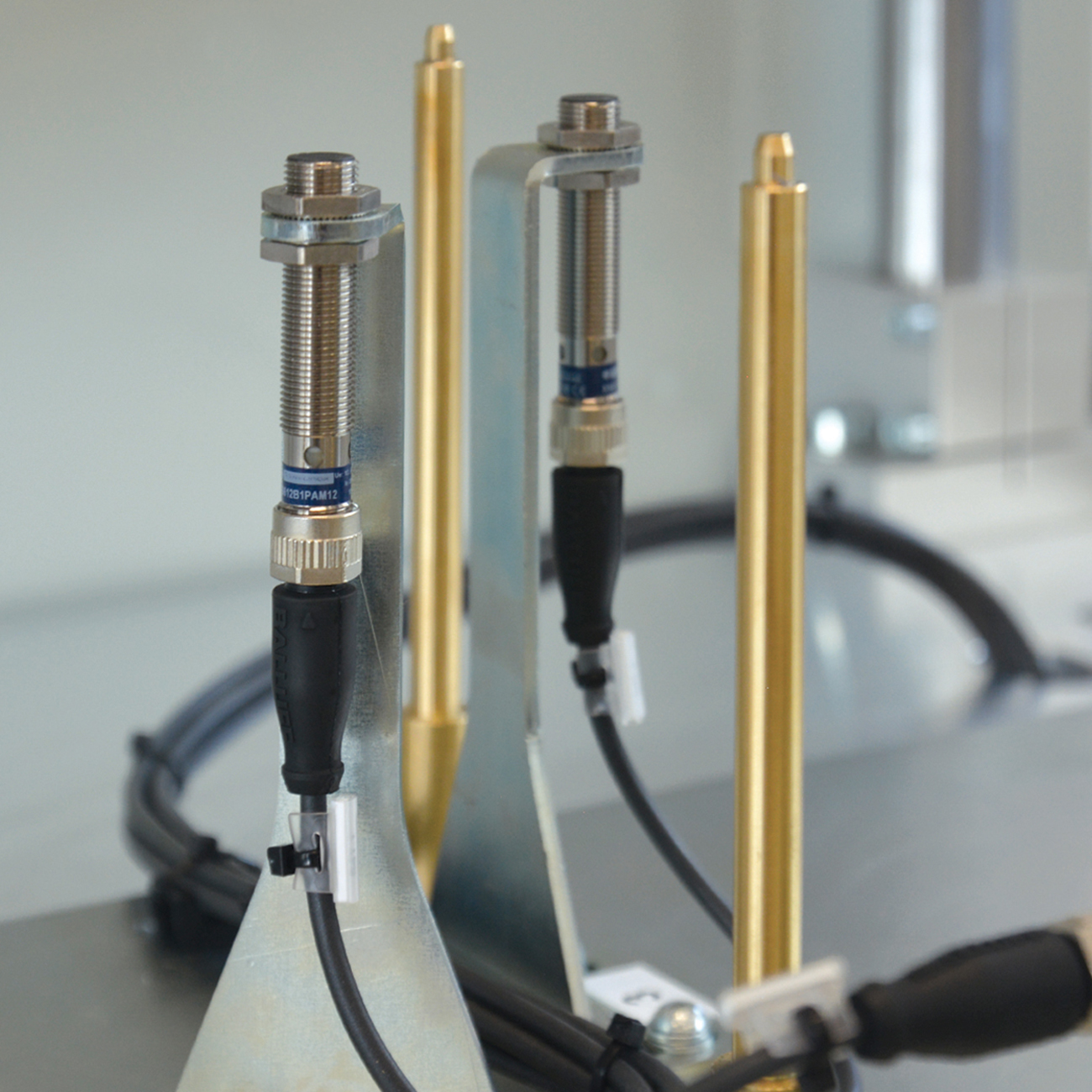

• Type recognition and workpiece positioning system with automatic program selection

• Exit from the rest area, nozzle purging and cleaning with air knife and brushes

• DowSil 7091 volumetric sealant dispensing with complete control of the quantity dispensed

• Dispensing managed by servo-controlled GP2 volumetric pump

• Volumetric dispensing, not conditioned by sealant temperature and pressure

• Laser system for dimensional measurement and continuity of the bead

• Complete process management via panel PC, with storage on the company server of the images taken after dispensing

CASE STUDY

Robotic Cell for Volumetric Dispensing of DowSil 7091 Sealant on Automotive Casings

The customer required an advanced solution for the volumetric dispensing of DowSil 7091 sealant on automotive casings. The goal was to ensure precise sealant application, integrated into an interpolated handling system, with complete real-time control and process parameter archiving. The solution needed to be compact and efficiently manage both the dispensing and cleaning processes.

01

Provided Solution

We designed and implemented a robotic cell that meets all the customer’s requirements, featuring the following characteristics:

Layout and Handling

Compact Layout

The system was designed with a compact layout and an interpolated portal handling system. This design optimizes space and improves operational efficiency, allowing for precise and smooth handling of the casing during the dispensing process.

Recognition and Automatic Selection

Recognition System

The system is equipped with automatic recognition of the part type and positioning, enabling the automatic selection of the appropriate dispensing program. This improves accuracy and reduces setup time.

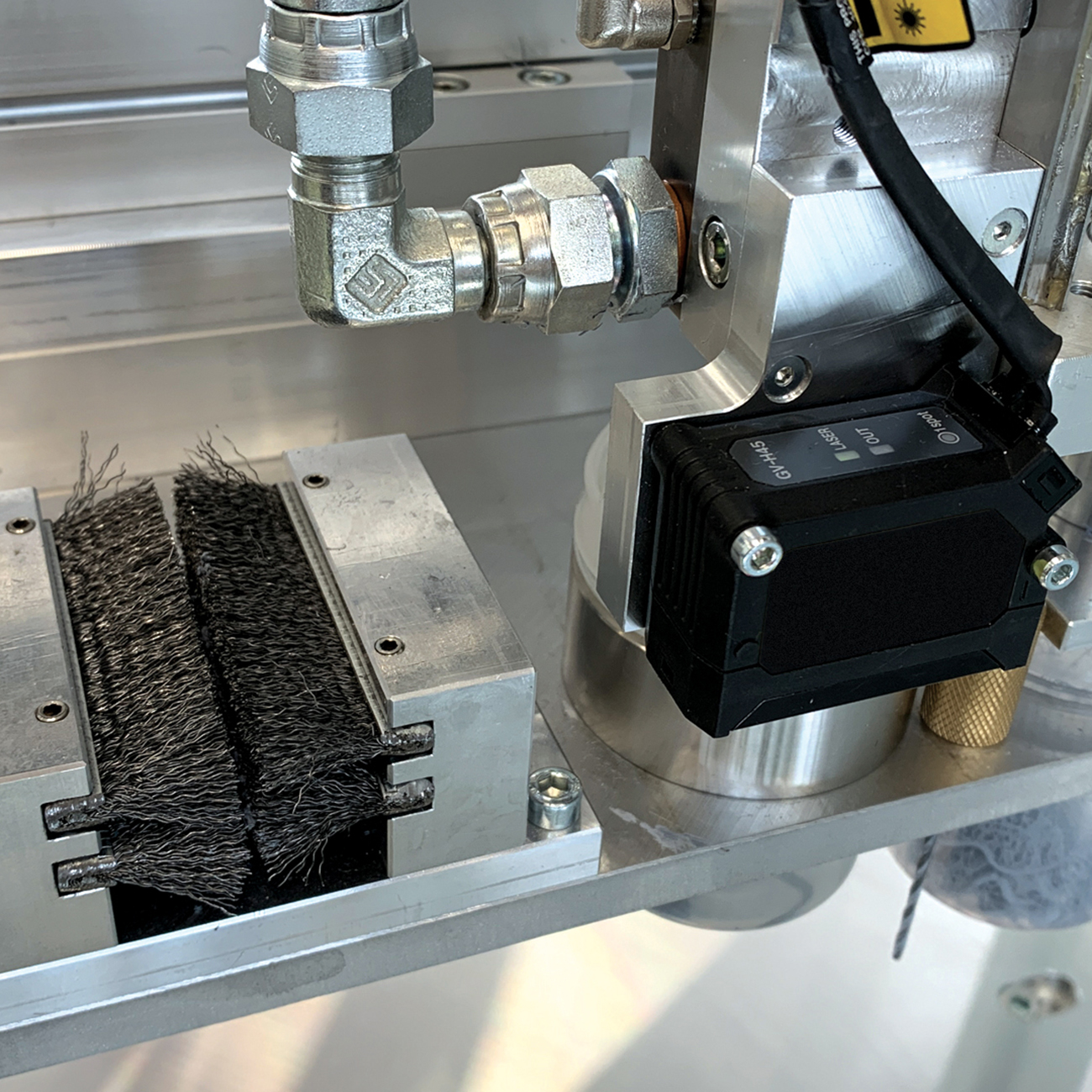

Cleaning and Maintenance

Exit from Rest Area

The cell includes an exit from the rest area, with a nozzle purging system and automatic cleaning via air blades and brushes. This ensures effective cleaning and keeps the system running smoothly without interruptions.

Advanced Volumetric Dispensing

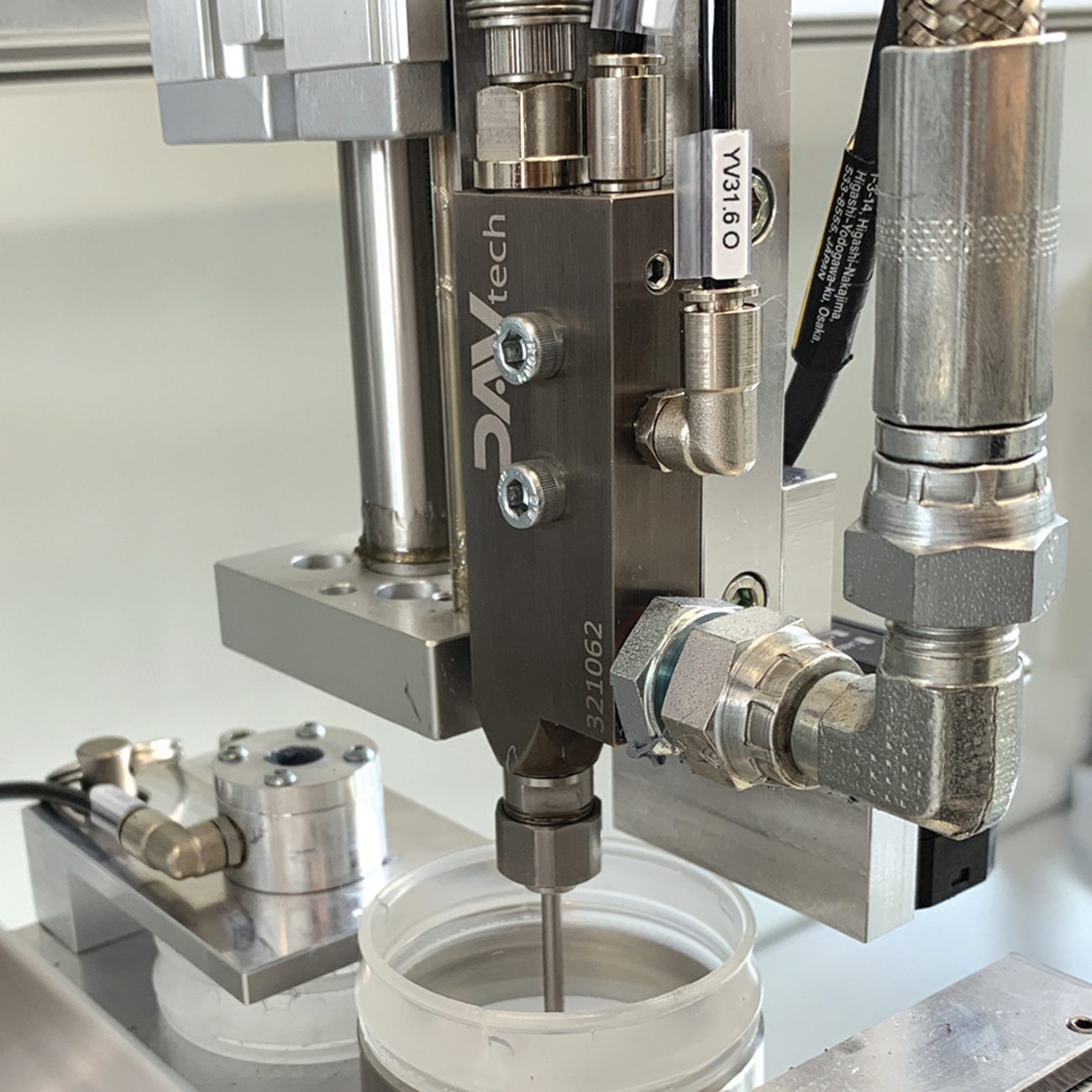

GP2 Volumetric Pump

The dispensing of DowSil 7091 sealant is managed by a servocontrolled GP2 volumetric pump, ensuring precise and consistent delivery, independent of variations in temperature and sealant pressure.

Control of Dispensed Quantity

Full control of the amount of sealant dispensed to ensure the quality and consistency of the process.

Control and Monitoring

Laser System

A laser system is used for dimensional measurement and verification of the sealant bead continuity, ensuring that the quality of the application meets the required standards.

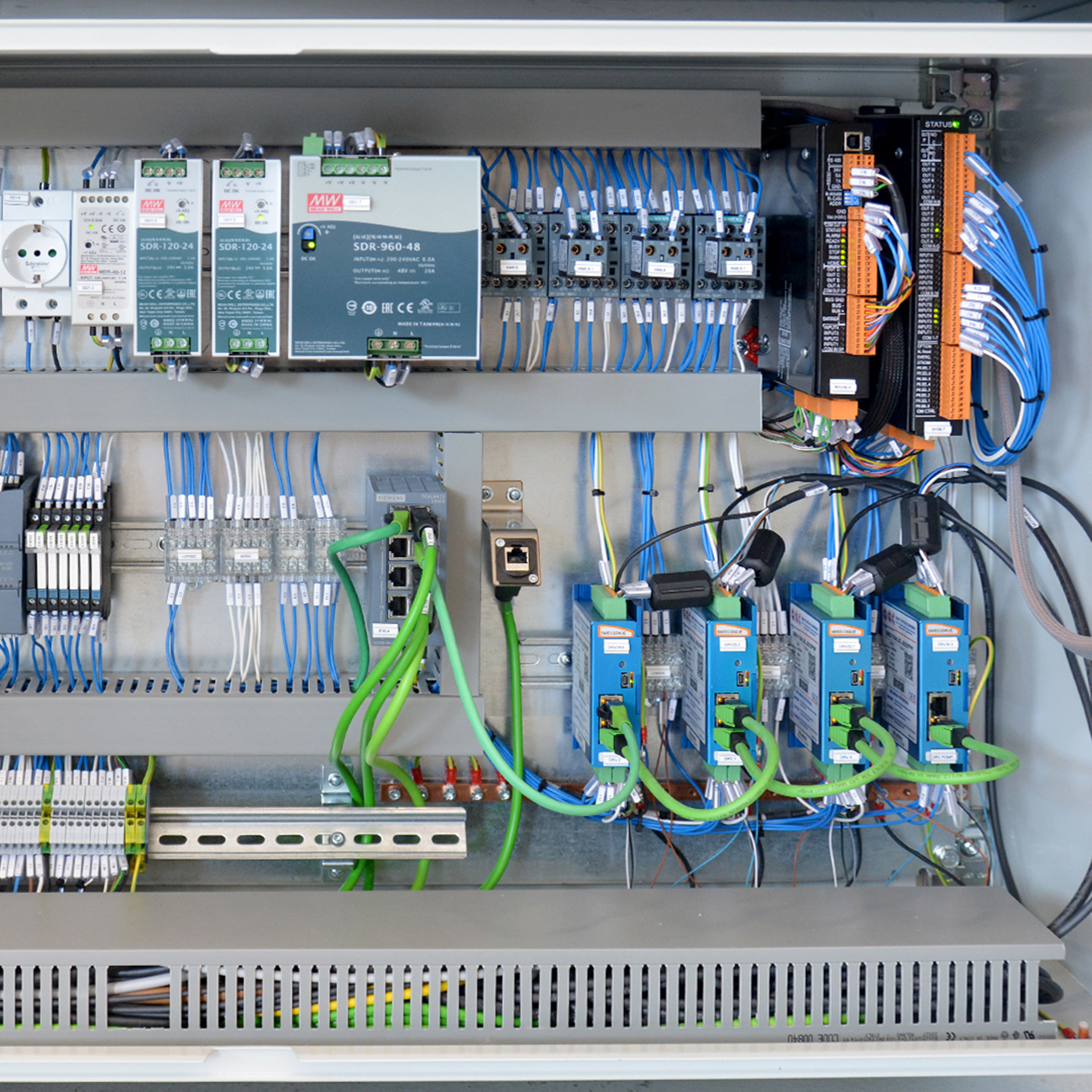

Panel PC Management

The complete process is managed via a panel PC, which allows for archiving images taken after dispensing on the company server. This ensures detailed traceability and accurate review of the process.

02

Results and Benefits

The robotic system provided optimized the DowSil 7091 sealant dispensing process, improving the accuracy and efficiency of the application. The compact layout and interpolated handling made the system highly flexible and adaptable to production needs. The automatic program selection and recognition system reduced setup times and improved the final product quality. The automatic cleaning and panel PC management simplified maintenance and ensured complete process traceability, contributing to better quality control and increased operational efficiency.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!