2K polyurethane bonding system WEVO PU 552 FL

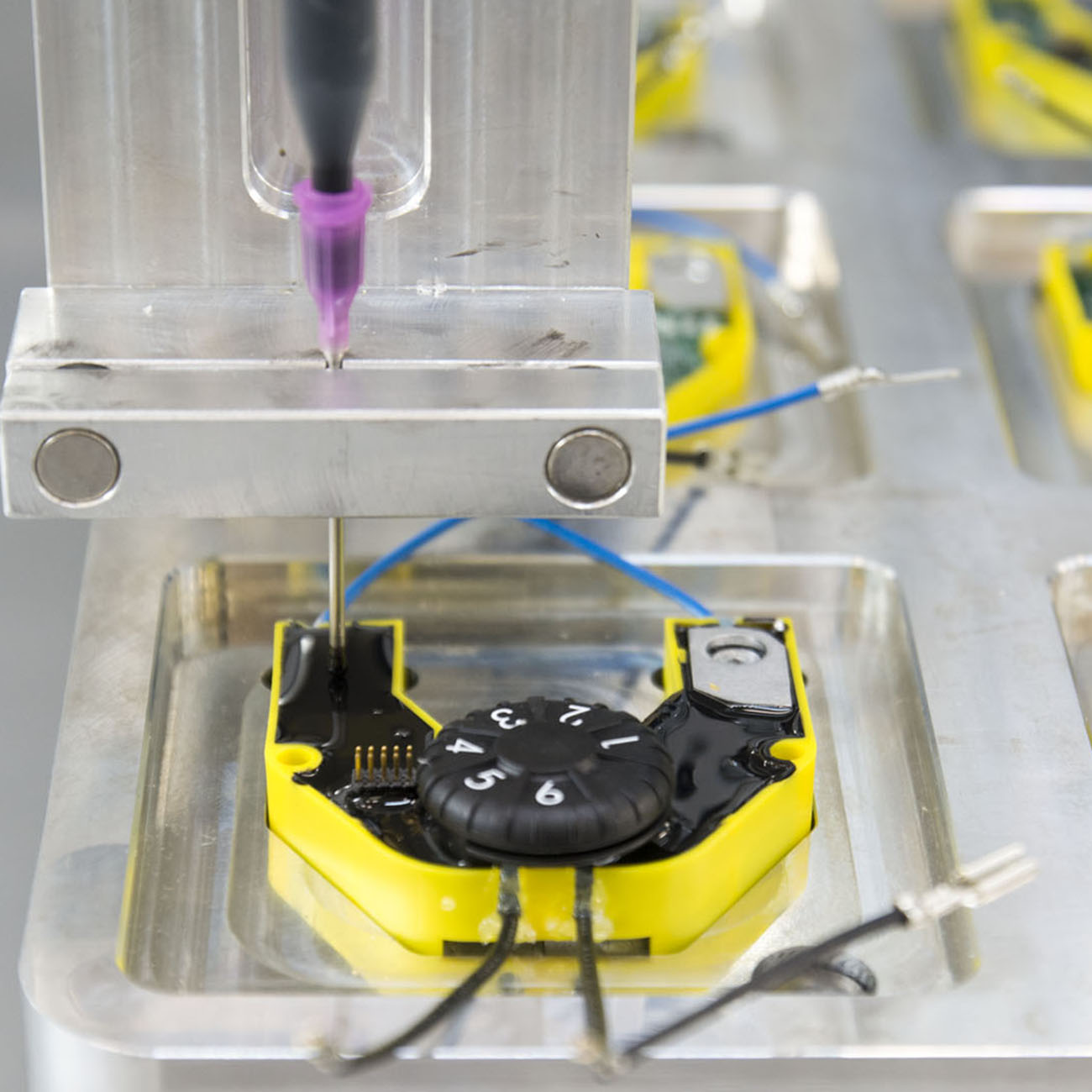

3-axis robotic system for volumetric dispensing of 2K polyurethane glue on electronic boards.

Management of the position and amount of resin dispensed.

Characteristics

• Interpolated 3-axis Cartesian system

• Volumetric dispensing by PDP double progressing cavity pump

• Program management via PDP Controller

• Mixer heating system to fluidize the resin

• Resin and hardener supply with thermo-controlled tanks equipped with agitator.

CASE STUDY

3-Axis Robotic System for Volumetric Dispensing of 2K Polyurethane Adhesive on Electronic Boards

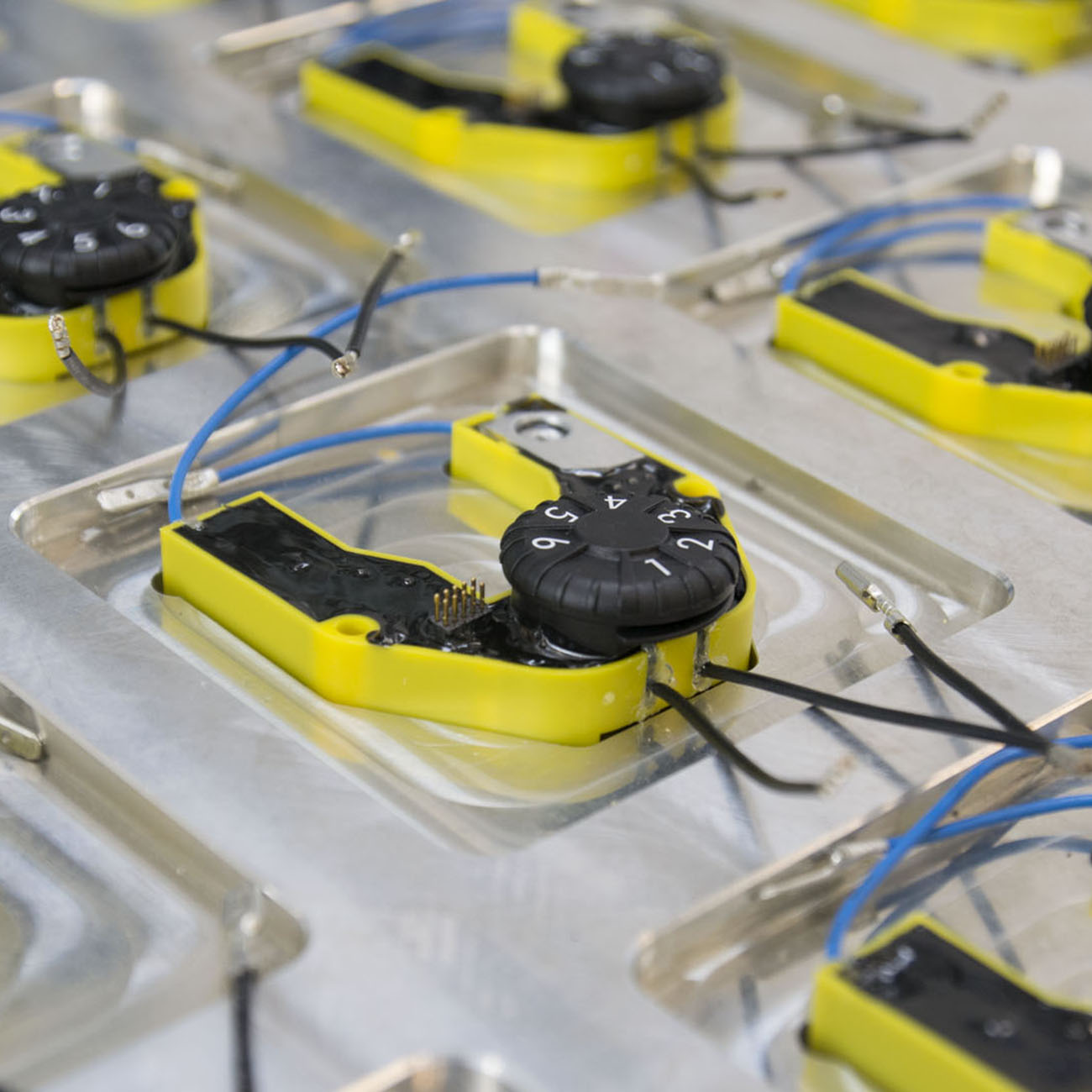

The customer required an advanced solution for the volumetric dispensing of 2K polyurethane adhesive on electronic boards. The main request was for a robotic system that would ensure precision in managing both the position and the quantity of resin dispensed, with particular attention to the viscosity of the adhesive and the management of dispensing programs.

01

Provided Solution

We designed and implemented a 3-axis Cartesian interpolated robotic system with the following features:

3-Axis Robotic System

Cartesian Motion

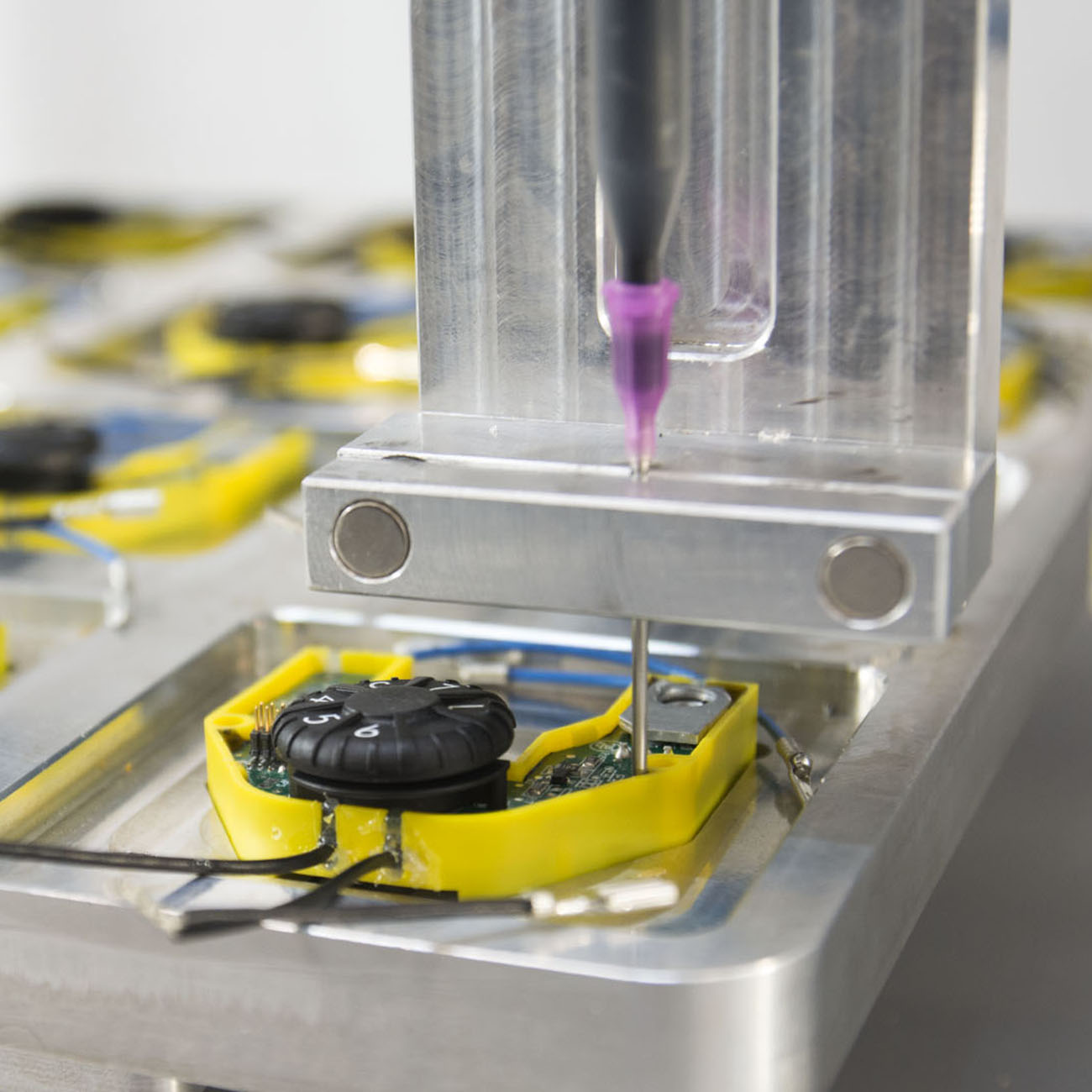

The system is equipped with a 3-axis Cartesian interpolated robot, allowing precise position and movement control to apply the adhesive accurately on electronic boards.

Advanced Volumetric Dispensing

PDP Single-Screw Pumps

The dispensing of the 2K adhesive is managed through a dual single-screw PDP pump setup. This configuration ensures precise and controlled dispensing of the resin and hardener.

Program Control

Dispensing programs are managed through a PDP Controller, which allows for the adjustment and optimization of dispensing parameters.

Adhesive Viscosity Control

Mixer Heating System

To ensure the optimal viscosity of the adhesive, the system is equipped with a heater for the mixer. This device maintains the resin at an appropriate temperature, facilitating a uniform and precise application.

Temperature-Controlled Tanks

The resin and hardener are supplied via temperature-controlled tanks with agitators. This ensures that the adhesive components remain well-mixed and ready for consistent dispensing.

02

Results and Benefits

The provided system brought several advantages to the 2K polyurethane adhesive dispensing process on electronic boards:

- Precision in Dispensing: The combination of the 3-axis robot and the PDP single-screw pumps ensured extremely precise volumetric dispensing, meeting the customer’s high quality and accuracy requirements.

- Optimal Viscosity Control: The mixer heating system and temperature-controlled tanks ensured that the adhesive maintained the required viscosity for smooth and uniform application.

- Efficient Program Management: The PDP Controller allowed for flexible and optimized management of dispensing programs, facilitating adaptation to different production requirements and improving operational efficiency.

- Reliability and Consistency: The system guaranteed high reliability and consistency in dispensing, helping improve the final product quality and reduce cycle times.

This robotic system provided a complete and advanced solution for dispensing 2K polyurethane adhesive on electronic boards, precisely addressing the customer’s needs and significantly improving the efficiency and quality of the production process.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!