With a “turnkey” approach, we address the specific fluid dispensing needs of our clients by fully customizing every aspect of the dispensing system.

Our problem-solving approach guides us in finding the most innovative and effective solutions.

We support the client through all stages of the production process, from A to Z, managing every phase internally, from consulting to after-sales service, ensuring versatility, quality, and optimal timing.

Manual Equipment

Practical and versatile solutions for manual dispensing operations, with guaranteed precision and ease of use.

One press

one dose

Small smart systems that ensure precise and controlled dosing with a single movement, customized to meet the client’s needs.

Cells with Cartesian Robots

Turnkey robotic dispensing stations, customized to the client’s specific requirements, integrable with vision systems, product weighing, Industry 4.0, traceability, etc.

Collaborative Robotics

Dispensing systems moved by collaborative robots for maximum programming flexibility and safety, creating stations where the boundary between the operator and the machine is minimized.

Other Robotic Cells

Customized robotic solutions that integrate fluid feeding, dispensing with volumetric valves or pumps, and process control.

Systems for 2K Fluids

We develop and supply systems dedicated to dispensing bi- components resins, with any mixing ratio.

Consulting

First and foremost, we are committed to fully understanding the client’s needs. Through close collaboration with our sales technicians and clear definition of objectives, we are able to offer personalized consulting. In our competence center, with possible preliminary tests, we can simulate and validate future processes in advance, ensuring maximum efficiency and quality.

Structural and Mechanical Design

Our team of experienced engineers is capable of designing everything in-house, from individual components to the complete dispensing system, from small manual stations to the most complex automation, fully customizing each element and handling the entire structure and mechanics of the system.

Using cutting-edge software and innovative approaches, with our three SolidWorks workstations, we create robust and reliable solutions tailored to the specific needs of the client.

Electrical Design

Our specialized electrical department focuses on the detailed design of electrical panels, ensuring that each customized station undergoes precise and thorough planning to fully utilize the system’s potential. Using dedicated software, we ensure maximum precision and reliability.

Pneumatic Design

We carefully select the most suitable pneumatic components for the project’s needs, such as pneumatic actuators, valves, and piping. The design of the pneumatic circuit is a crucial phase, aimed at achieving the ideal size and suitability for the process.

The pneumatic system is then integrated with the plant’s control system, using PLC and HMI to manage operations according to the process specifications.

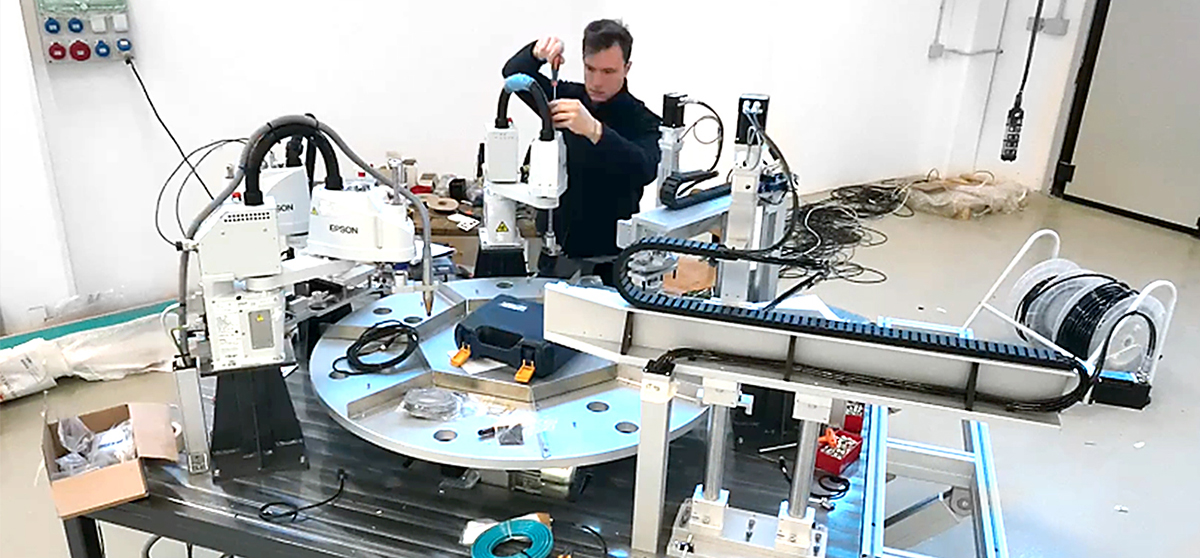

Construction and Assembly

At our facilities, the construction and assembly process is carried out with attention to detail and the use of high-quality materials. Each component is carefully integrated to ensure smooth and reliable system operation.

Onboard Wiring

Wiring is carried out by our experts with care and precision to ensure a stable and secure connection between the various components of the system, minimizing the risk of failures and malfunctions.

Onboard wiring is essential to ensure that all electrical components function properly and communicate effectively with each other. It is designed to be resistant to vibrations, extreme temperatures, and other environmental stresses.

The design is also intended to make the system easily accessible for installation, maintenance, and any repairs.

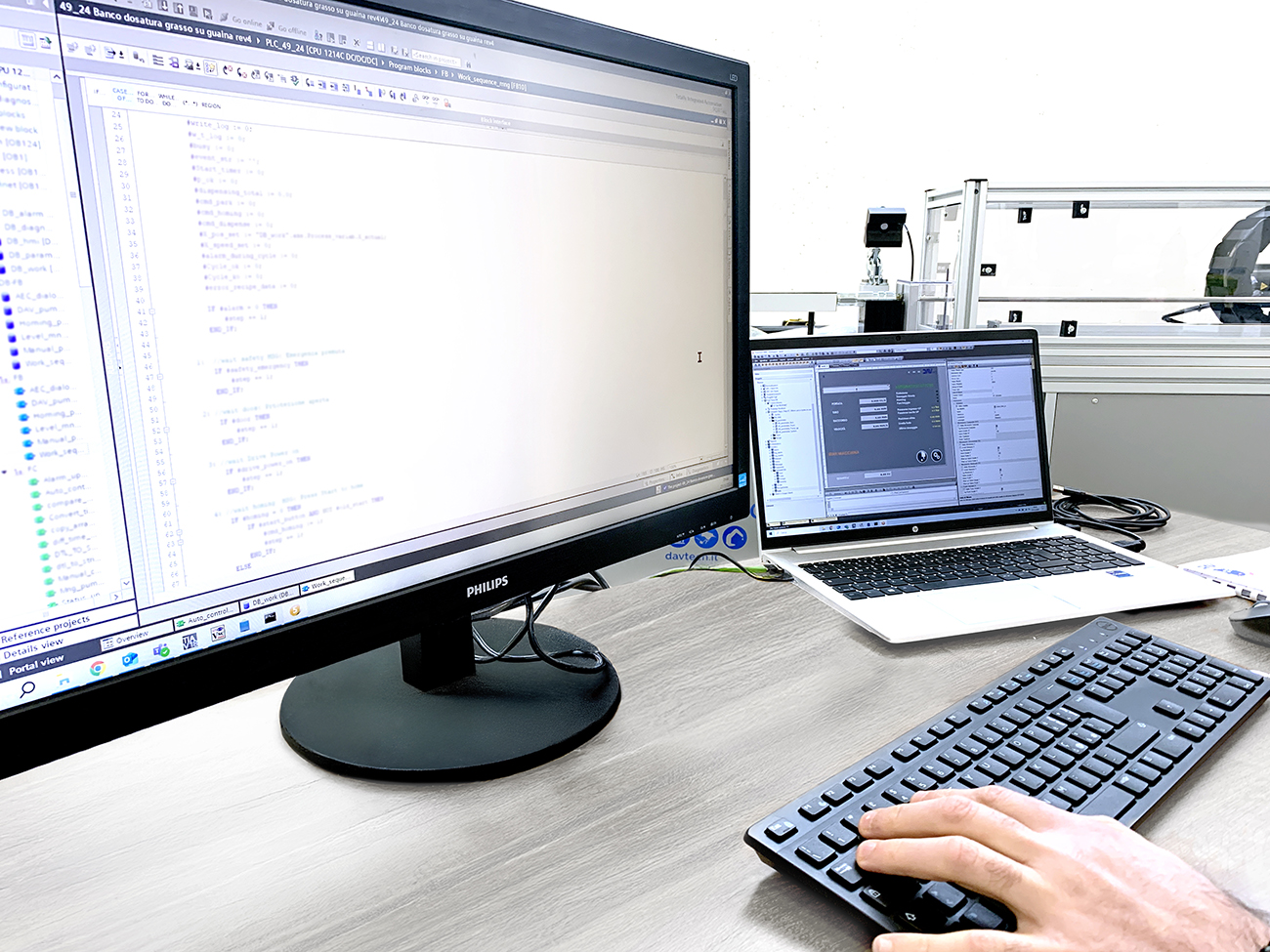

Software Programming

We are committed to ensuring an intuitive and functional interface for optimal control of the dispensing process, as well as providing advanced solutions for traceability. Through advanced and in-house programming of PLCs, HMIs, and Industry 4.0 solutions, we customize the system software to meet the specific needs of the client.

Traceability allows for monitoring and recording every stage of the dispensing process, providing and storing detailed information about the completed process. This additional feature enables data management generated by the system, improves safety, and facilitates compliance with regulatory requirements and industrial compliance practices.

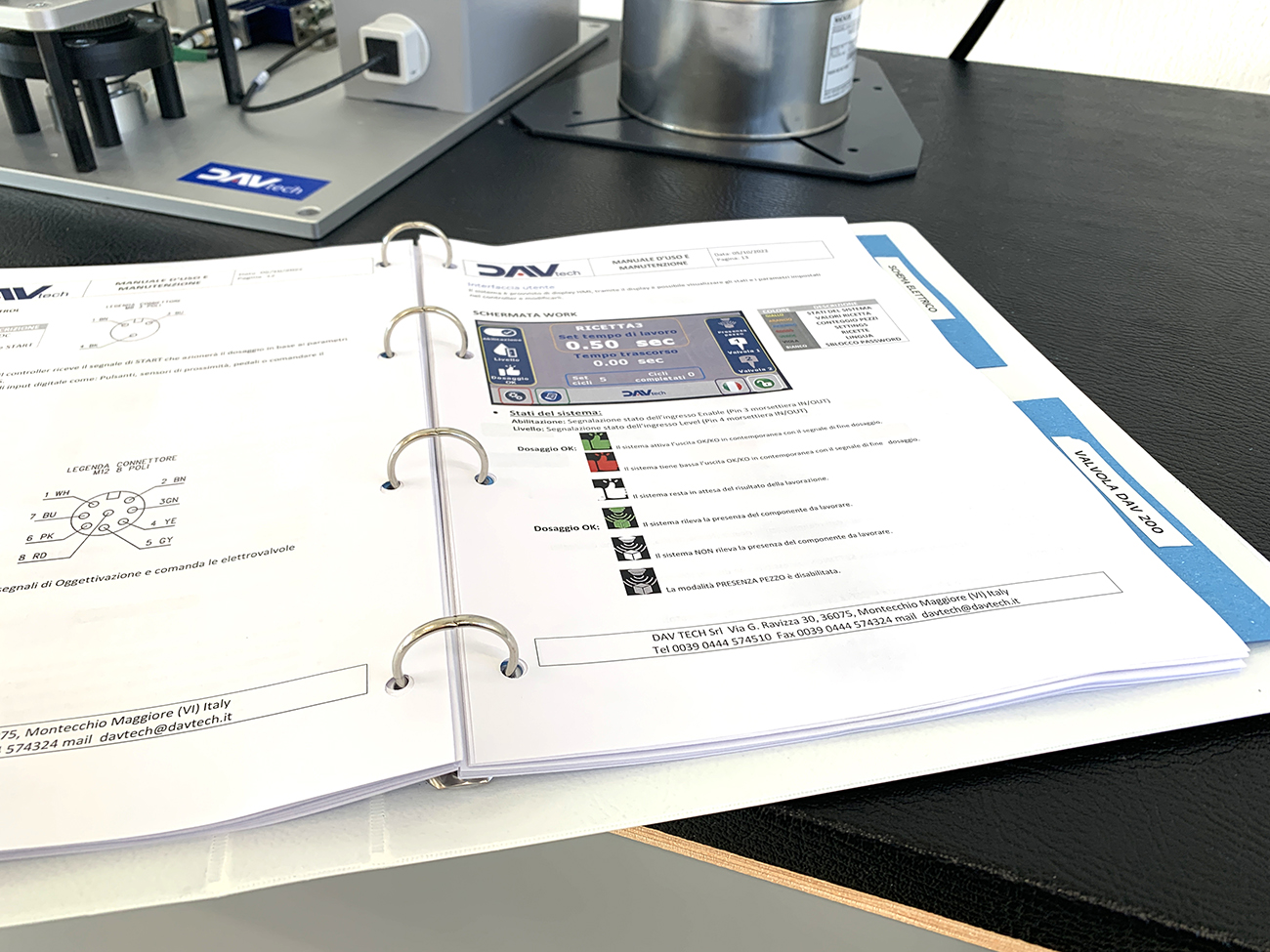

Preparation of Related Documentation and Certifications

We handle the preparation of all complete and detailed documentation related to the system, including operating instructions and conformity certifications.

We ensure that the client has all the necessary information to use the system safely and in compliance with regulations.

Testing and Verification

Before delivery, we conduct a thorough testing process at our facility. We verify that the system operates correctly and fully meets the specified requirements.

Packaging and Shipping

With care and attention, we securely package the system to ensure its integrity during both domestic and international transport. We work with reliable partners to ensure timely and safe deliveries.

Start-up and Integration

At the customer’s facility, we ensure that the system is properly started up and effectively integrated with other existing stations or processes.

Operator Training

We provide specialized training for operators, ensuring they have the necessary skills to use the system efficiently and safely.

Remote or On-Site Technical Support

Our technical support team is always available to provide remote assistance, troubleshoot issues, and optimize system performance over time.

Our service hotline is active and available for chat, calls, or the new augmented reality remote assistance service.