FEEDING

• Pressurized tank (available in various sizes and versions) with pressure regulation and level control.

DISPENSING

• Spray valve with a special extension for 360° radial, contactless dispensing.

PROCESS CONTROL

• HMI/PLC controller for dispensing process management, 4.3” color display.

• Dedicated multilingual graphical interface.

• Easy interface with external PLCs via dedicated I/O ports.

• Cycle counter function, with good (OK) – no good (KO) feedback.

• Possibility to create multiple programs.

• Option to interface a part presence sensor or dispensing check sensor.

• Separate management of air pressure and working time for both actuation and blow-off air.

| FIELDS OF APPLICATION |

|---|

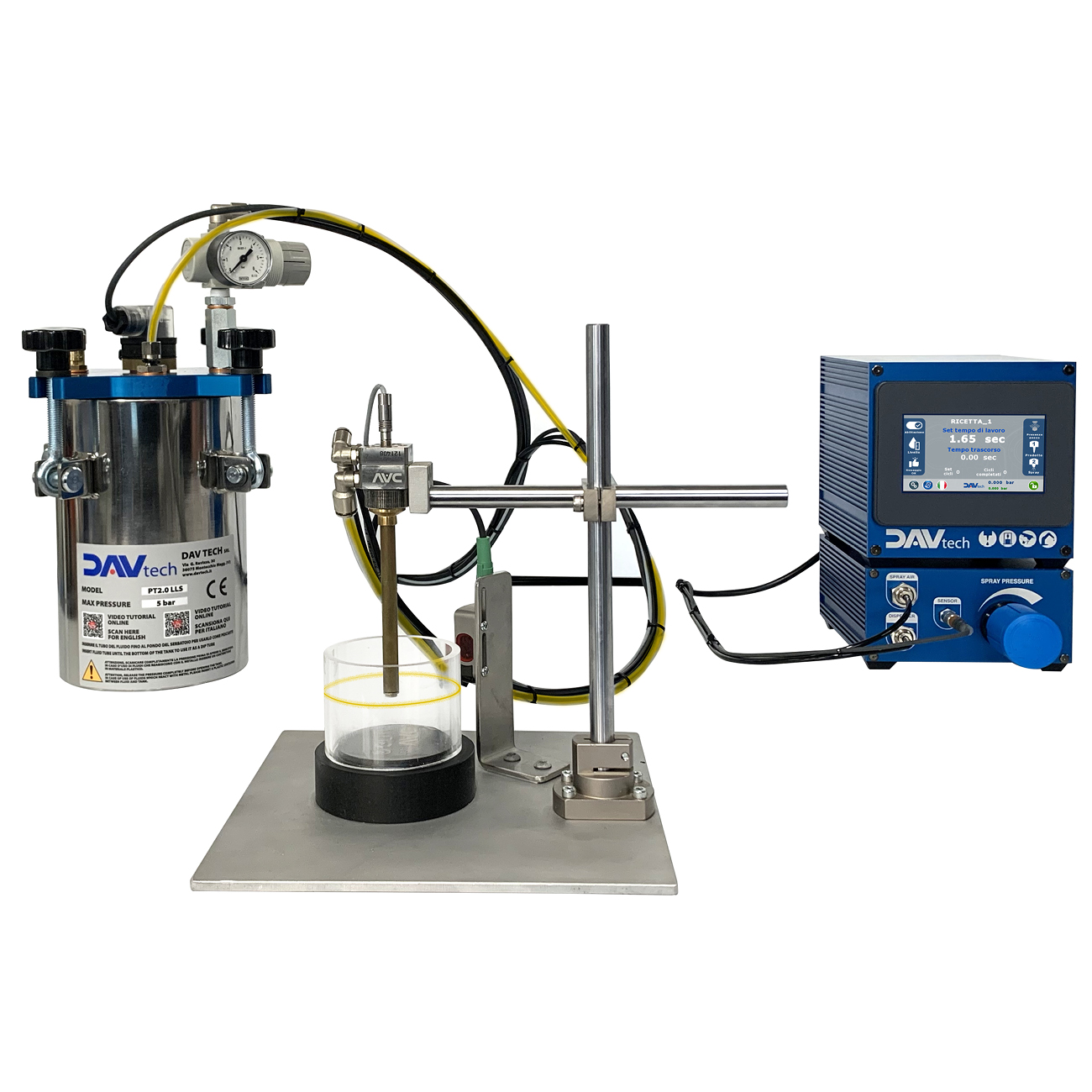

Controlled Radial Spray Dispensing System

The radial spray valve system is designed for precise and controlled dispensing. The controller allows parameterization of the valve opening times, as well as the timing and pressure of the additional air.

FEEDING

• Pressurized tank (available in various sizes and versions) with pressure regulation and level control.

DISPENSING

• Spray valve with a special extension for 360° radial, contactless dispensing.

PROCESS CONTROL

• HMI/PLC controller for dispensing process management, 4.3” color display.

• Dedicated multilingual graphical interface.

• Easy interface with external PLCs via dedicated I/O ports.

• Cycle counter function, with good (OK) – no good (KO) feedback.

• Possibility to create multiple programs.

• Option to interface a part presence sensor or dispensing check sensor.

• Separate management of air pressure and working time for both actuation and blow-off air.

| FIELDS OF APPLICATION |

|---|