FEEDING

• Suction of the sealant directly from the original drum, avoiding waste and transfers

• Drum level control

• Possibility of remote positioning of the pump from the dispensing system

DISPENSING

• Gear-based volumetric pump with servo control

• Motor with integrated encoder for precise process control

• Pressure transducers at the pump inlet and outlet

• Pump with special seals and integrated oil bath buffer

• Robust and easy-to-maintain structure

• Needle dispensing valve directly managed by the controller

• Volumetric dispensing, unaffected by variations in viscosity, pressure, and temperature

PROCESS CONTROL

• Easy interface with line PLC via Modbus TCP

• Full management of all dispensing parameters

• Operation modes for jog or filling

• Precise dispensing management, with automatic purging options

• Remote or panel selection of unlimited programs

• Remote connection available for tele-assistance

• Multilingual graphical interface

| FIELDS OF APPLICATION |

|---|

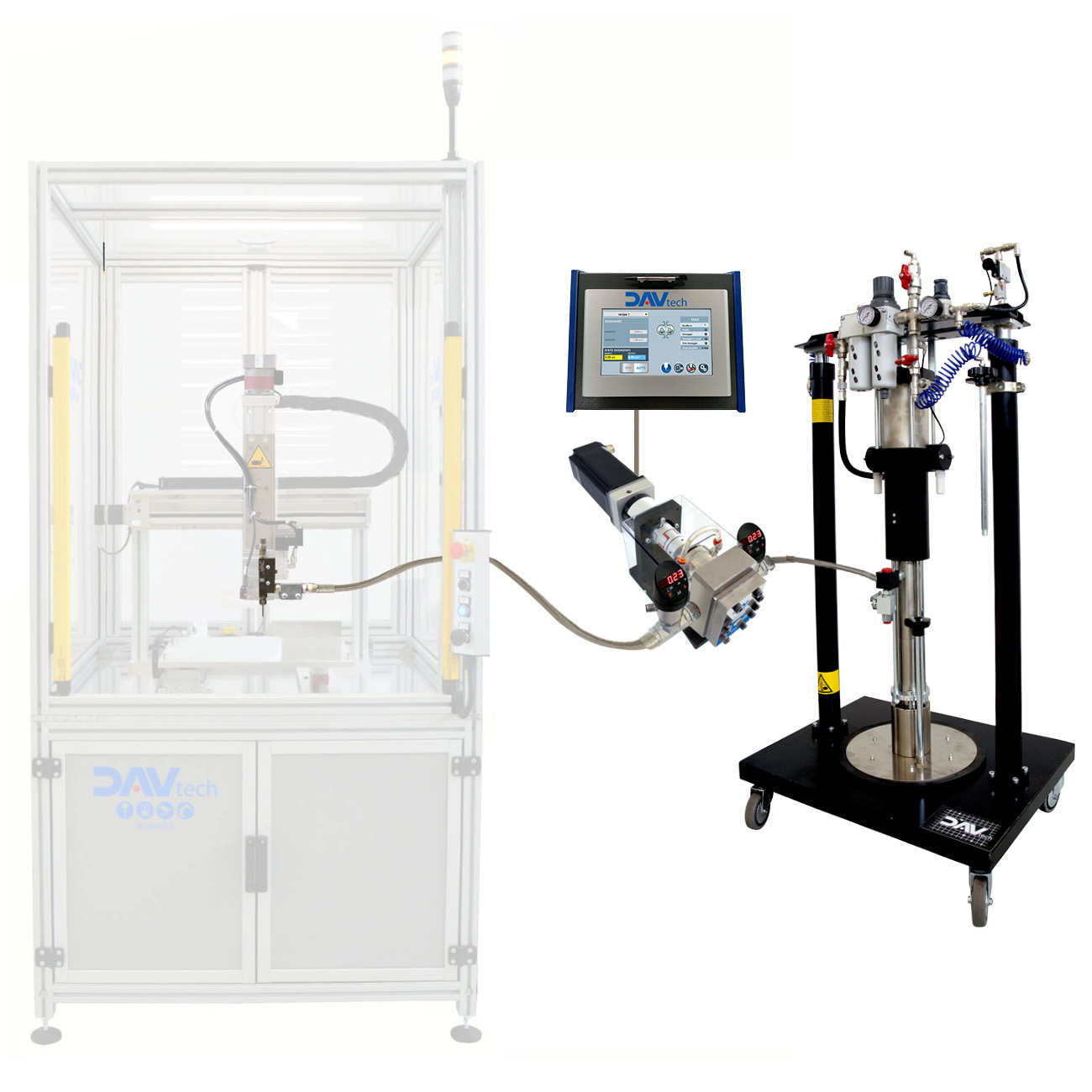

Volumetric dispensing system for Sealants in drums

System for volumetric management of sealing processes with adhesives (silicone-based and others) contained in drums of various sizes.

FEEDING

• Suction of the sealant directly from the original drum, avoiding waste and transfers

• Drum level control

• Possibility of remote positioning of the pump from the dispensing system

DISPENSING

• Gear-based volumetric pump with servo control

• Motor with integrated encoder for precise process control

• Pressure transducers at the pump inlet and outlet

• Pump with special seals and integrated oil bath buffer

• Robust and easy-to-maintain structure

• Needle dispensing valve directly managed by the controller

• Volumetric dispensing, unaffected by variations in viscosity, pressure, and temperature

PROCESS CONTROL

• Easy interface with line PLC via Modbus TCP

• Full management of all dispensing parameters

• Operation modes for jog or filling

• Precise dispensing management, with automatic purging options

• Remote or panel selection of unlimited programs

• Remote connection available for tele-assistance

• Multilingual graphical interface

| FIELDS OF APPLICATION |

|---|