FEEDING

• Cartridges (available in various sizes and dimensions) with minimum level management and alarm

• Quick cartridge attachment system and manual purge

DISPENSING

• Gear motors controlled via encoders

• Tungsten carbide rotors for high abrasion resistance

• Pressure transducers for full process control

• Mixer guide rod for maximum positioning accuracy

• Continuous operation without reloading times

• Volumetric dispensing, unaffected by variations in viscosity, pressure, and temperature

PROCESS CONTROL

• Management of the entire process (feeding, dispensing, alarms, etc.) from a single interface

• Simple line PLC interfacing via Modbus TCP

• Complete management of all dispensing parameters

• Jog or filling mode operation management

• Precise dosed quantity management, with automatic purging capability

• Separate dispensing mode for A and B for setup

• Remote or panel selection of infinite programs

• Remote connection for tele-assistance

• Multilingual graphical interface

• Integrated tele-assistance system.

| FIELDS OF APPLICATION | 2K adhesive |

|---|

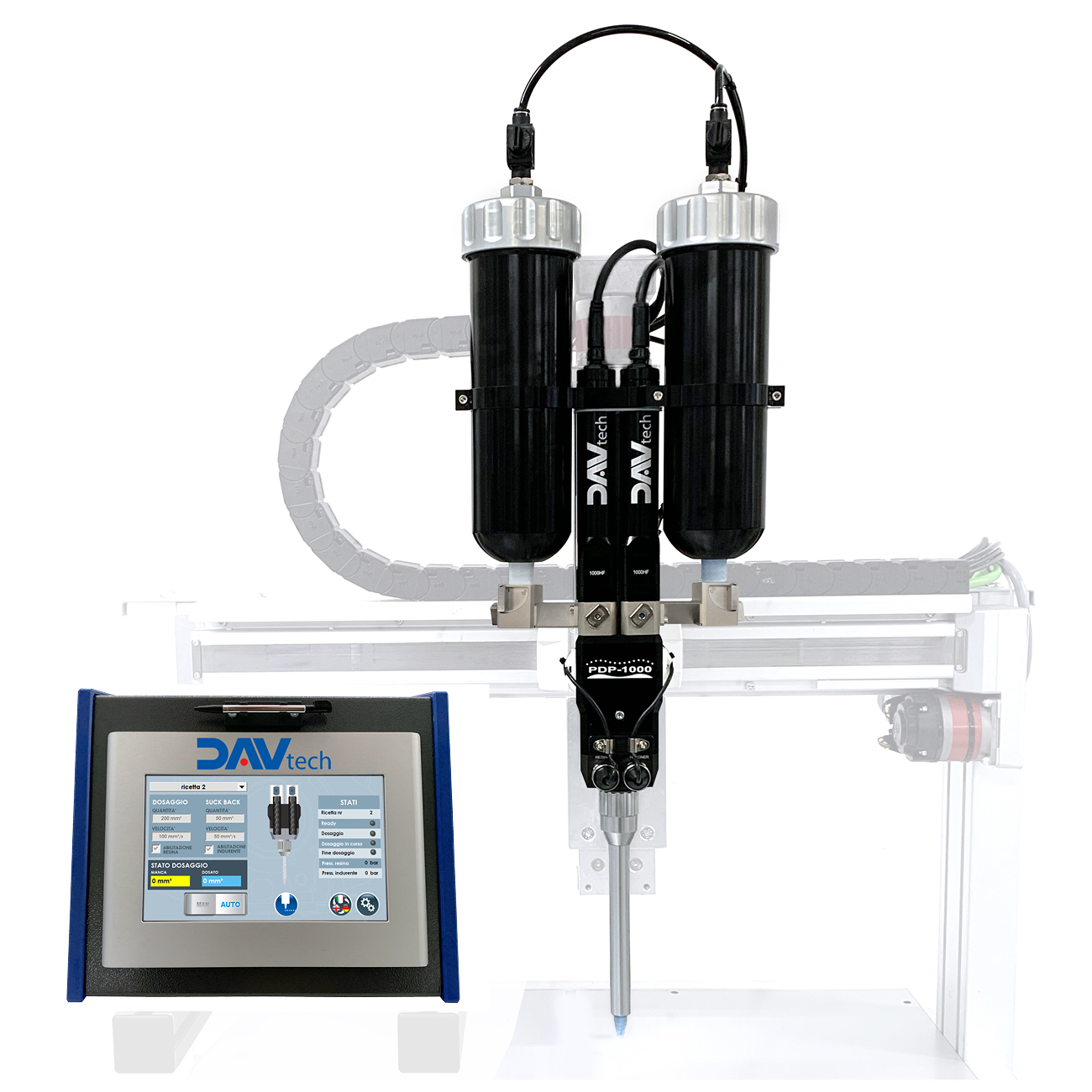

Volumetric dispensing system for Thermally Conductive Pastes and Gap Fillers in cartridges

Ideal dispensing system for highly abrasive fluids such as thermally conductive pastes and bi-component gap fillers. Fluid A and B are supplied from pre-filled cartridges.

FEEDING

• Cartridges (available in various sizes and dimensions) with minimum level management and alarm

• Quick cartridge attachment system and manual purge

DISPENSING

• Gear motors controlled via encoders

• Tungsten carbide rotors for high abrasion resistance

• Pressure transducers for full process control

• Mixer guide rod for maximum positioning accuracy

• Continuous operation without reloading times

• Volumetric dispensing, unaffected by variations in viscosity, pressure, and temperature

PROCESS CONTROL

• Management of the entire process (feeding, dispensing, alarms, etc.) from a single interface

• Simple line PLC interfacing via Modbus TCP

• Complete management of all dispensing parameters

• Jog or filling mode operation management

• Precise dosed quantity management, with automatic purging capability

• Separate dispensing mode for A and B for setup

• Remote or panel selection of infinite programs

• Remote connection for tele-assistance

• Multilingual graphical interface

• Integrated tele-assistance system.

| FIELDS OF APPLICATION | 2K adhesive |

|---|