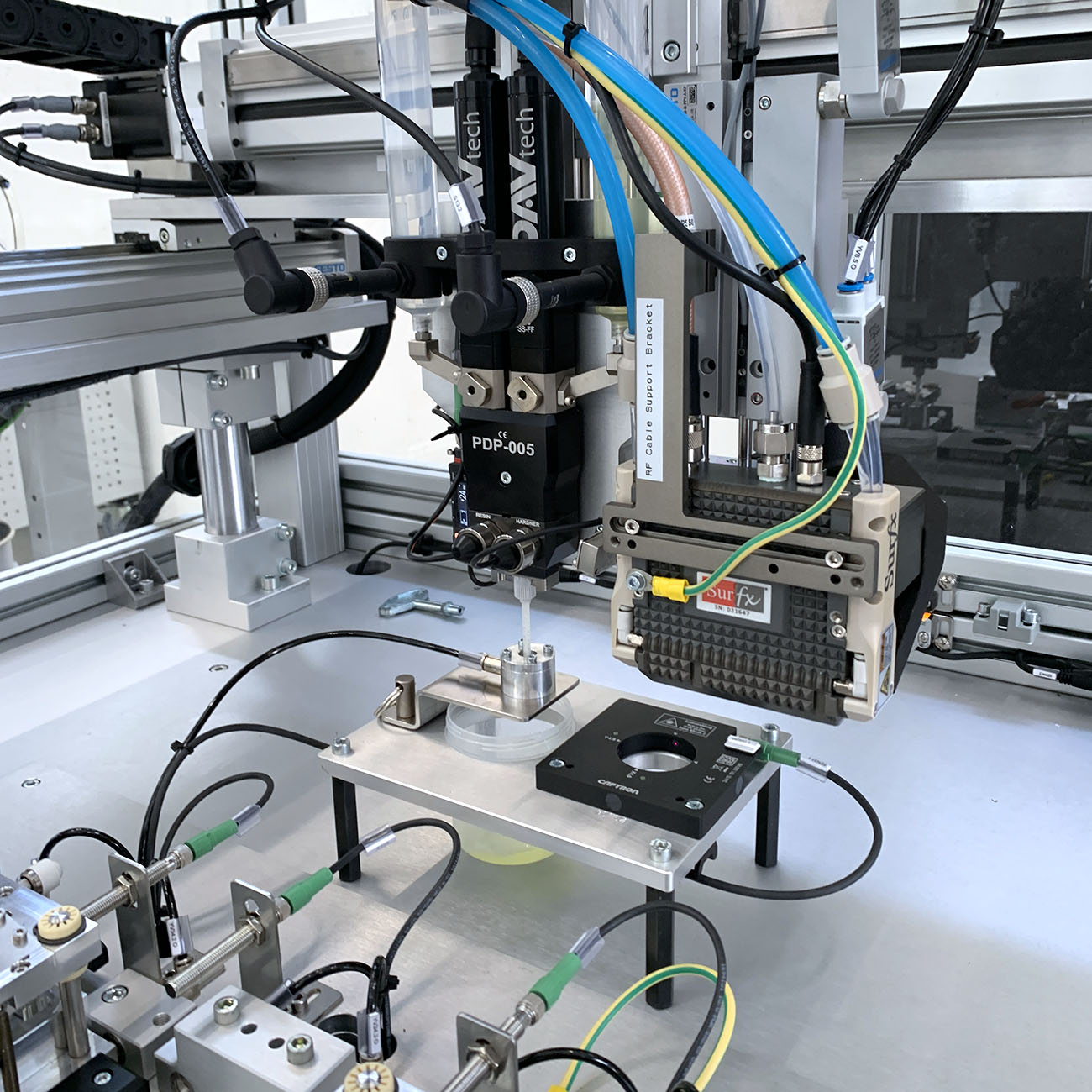

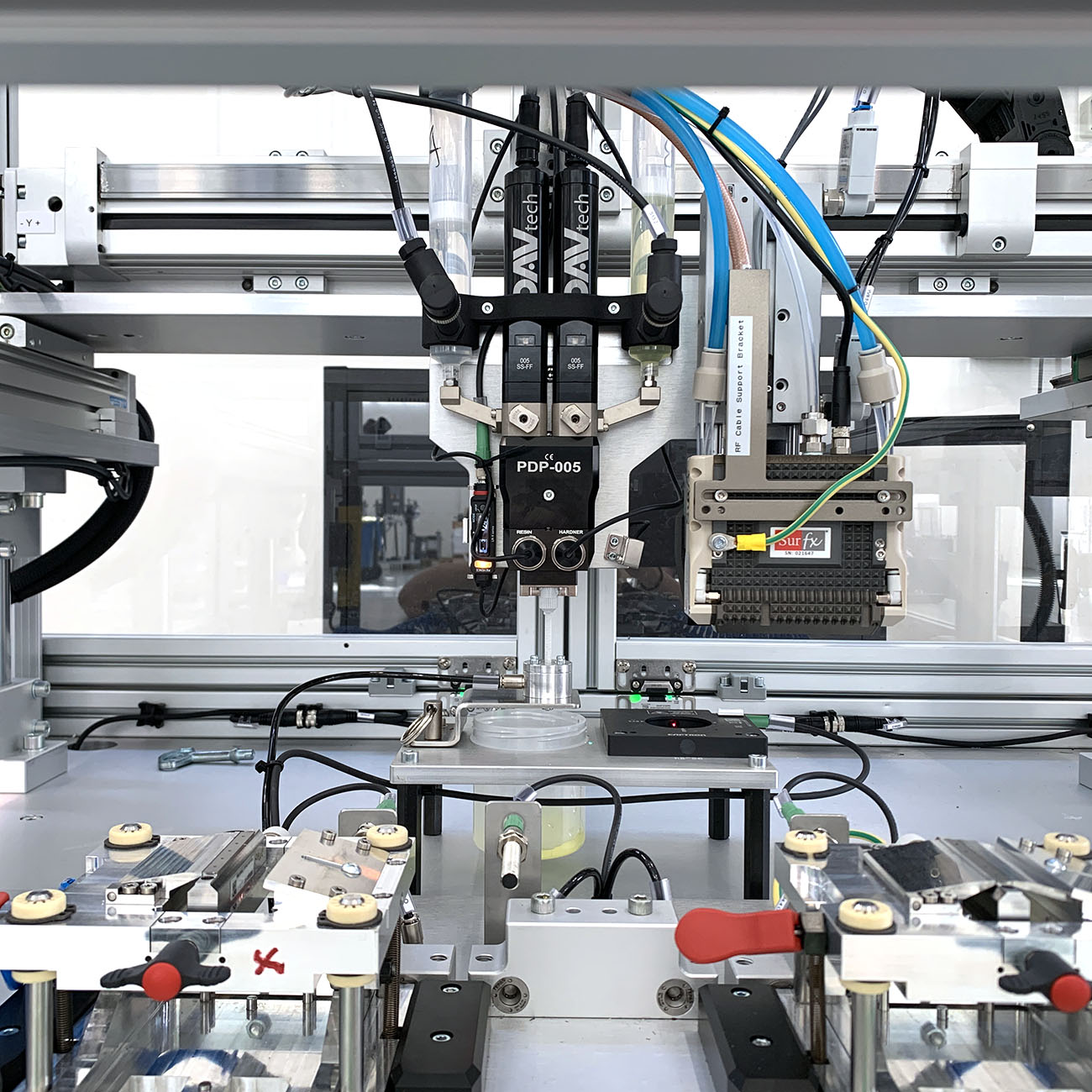

Epoxy resin microdispensing system

Micro-quantity dispensing of 2K epoxy resin with MKH3-16S mixer.

Characteristics

CASE STUDY

2K Micro Quantity Epoxy Resin Dispensing System with MKH3-16S Mixer

The 2K epoxy resin micro quantity dispensing system is designed to ensure maximum precision and reliability in the dispensing of high-precision resins. It uses a 3-axis electric Cartesian robot and an MKH3-16S mixer to handle micro quantities with high repeatability and process control.

01

Our solutions

Main features:

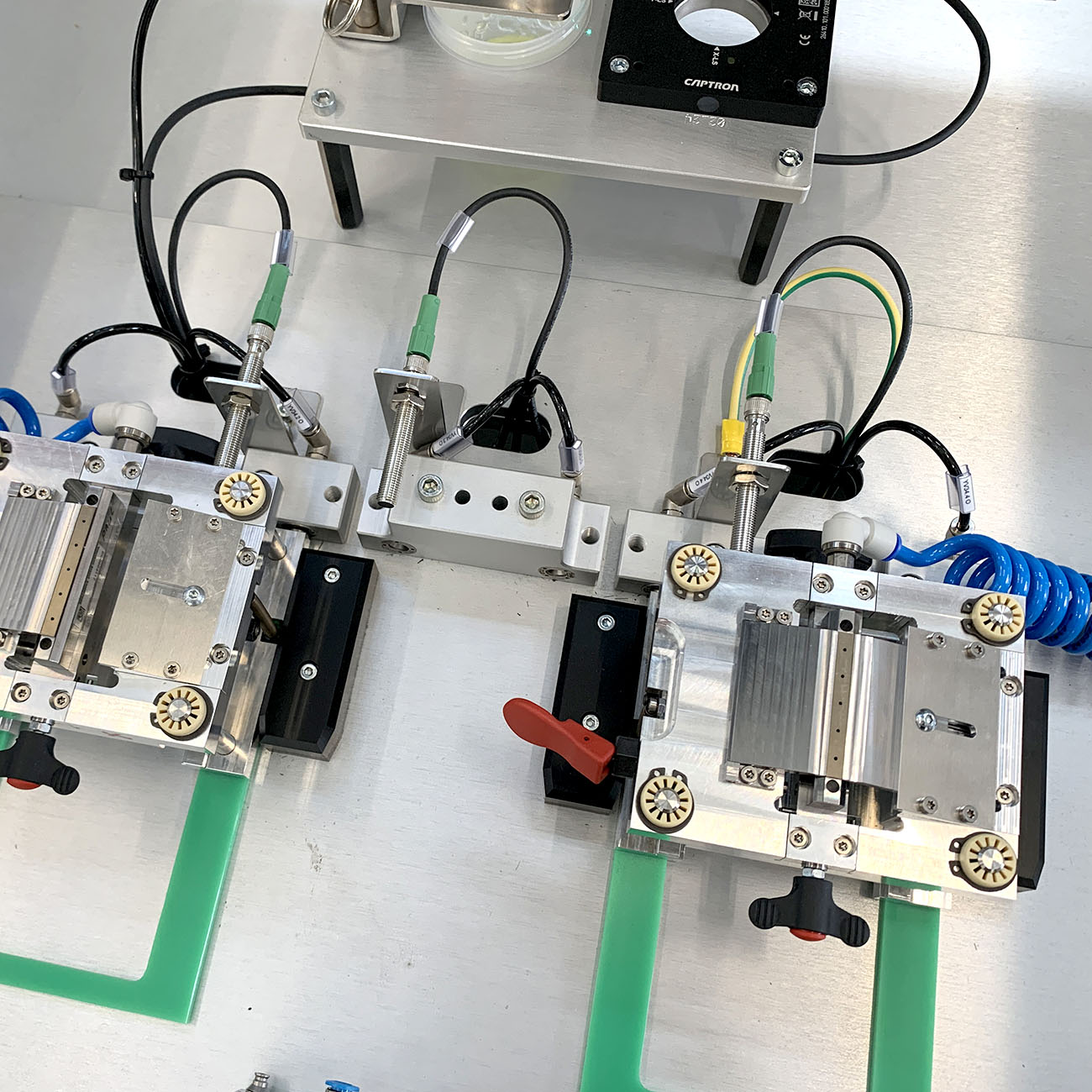

3-axis Cartesian robot

Type

Cartesian robot with 3 electric axes.

Accuracy

Positioning repeatability of ±0.02 mm thanks to ground ball screws on the 3 X-Y-Z axes.

Motion

3D linear interpolation with movement of points, lines, areas, arcs, and circles.

Control and Programming

Master Board

For 3D linear interpolation and handling of complex movements.

PLC Control

Allows remote selection and management of programs.

Calibration Sensor

Automatic for correcting the position of the static mixer on the 3 XYZ axes.

Dispensing and Mixing

Volumetric pump

PDP 005 2 components, equipped with motors and static mixers for accurate mixing of 2K resins.

Power supply

Two 10 CC cartridges for resin and catalyst dispensing.

Pressure and Process Management

Pressure Management System

Ensures the correct pressure for precise dispensing.

HMI Unit

Manages pump operations and dispensing parameters via user interface.

Automatic Cleaning

Cleaning System

Automatic, based on motorized brushes to clean the nozzle after each cycle, keeping the nozzle in optimal condition and preventing clogging.

02

Results and Benefits

Benefits of the System

- High Accuracy: The positioning repeatability of ±0.02 mm and the automatic calibration system ensure precise and consistent dispensing.

- Programming flexibility: The ability to select and manage remote programs via PLC makes it easy to adapt to different processes and applications.

- Process Efficiency: The pressure management system and automatic cleaning reduce downtime and increase operational efficiency.

- Full Control: The main HMI unit and control PLC provide centralized and optimized management of the dispensing process.

In conclusion, the MKH3-16S 2K Epoxy Resin Micro Quantity Dispensing System with Mixer is an advanced and highly accurate solution for applications in electronics and other industries that require micro dispensing. Thanks to its high precision, automatic calibration capability, and integrated cleaning system, the system is ideal for ensuring consistent and reliable results in high-precision resin dispensing.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!