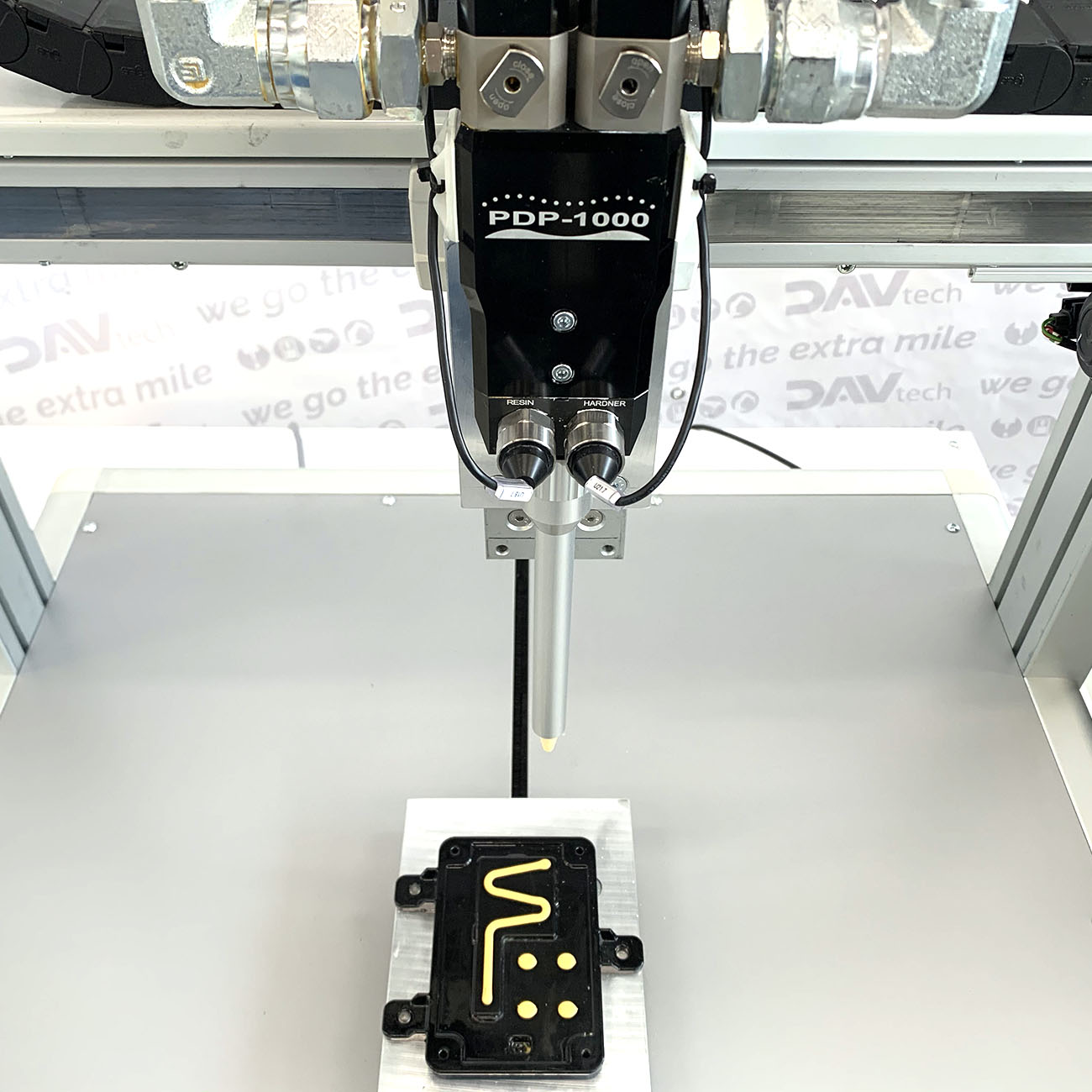

Bergquist 1500 Gap filler volumetric paste dispensing system

The most modern solution for the volumetric dispensing of thermally conductive pastes and gap fillers, made with servo-controlled progressive cavity pumps, for fluid feeding and dispensing.

Maximum dispensing precision, and minimum wear of the components, thanks to the use of high-strength materials and the innovative operating principle, which does not stress the fluids, avoiding subjecting them to high pressures.

Solution ready to be integrated on robots, cobots, and Cartesian robots, with complete control of the parameters of the dispensing process via PLC and HMI, interfaced in Profinet to the assembly line.

Characteristics

CASE STUDY

Volumetric Dispensing System for Thermally Conductive Pastes and Gap Fillers: Advanced Solution

The volumetric dispensing system for thermally conductive pastes and gap fillers is designed to ensure maximum precision and reliability. It uses servo-controlled progressive cavity pumps for optimal fluid feeding and dispensing. The solution features high material durability and an innovative operating principle that avoids excessive stress on the fluids, maintaining low working pressures.

01

Our solution

Key Features:

Servo-Controlled Pumps

Type

Servo-controlled progressive cavity pumps.

Control

Managed via inverters for precise control and continuous flow adjustment.

Materials

Wear-resistant carbide rotor to minimize component wear and ensure long system life.

Dispensing Precision

Fluid Control

The pumps are designed for precise dispensing, avoiding high pressures that could stress the fluids.

Pressure Transducers

Used for real-time feedback to ensure consistent flow and accurate dispensing.

Management and Monitoring

Analog Sensor

For fluid level control, ensuring tanks are always adequately replenished.

Drum Presence Sensor

Ensures drums are always correctly positioned and ready for feeding.

Drum Centering System

Facilitates the precise and safe insertion and positioning of drums.

Integration and Control

Interface

The system is designed to integrate with robots, cobots, and Cartesian robots.

PLC and HMI

Full process parameter control through PLC and HMI interface, connected to the assembly line via Profinet, for centralized and optimized management

Design and Maintenance

High-Durability Materials

Used to ensure long life and reliability, minimizing required maintenance.

HMI

Provides complete process management, allowing easy configuration and monitoring of dispensing parameters.

02

System Benefits

- High Precision: The combination of servo-controlled pumps and advanced sensors ensures extremely precise and repeatable volumetric dispensing.

- Low Wear: The use of high-durability materials and the low-pressure operating principle reduce component wear and extend system life.

- Versatility: Compatibility with various types of robots and ease of integration into the assembly line make the system highly versatile.

- Complete Control: The system offers full centralized control through PLC and HMI, optimizing process management and improving operational efficiency.

In conclusion, our volumetric dispensing solution for thermally conductive pastes and gap fillers represents the latest technology in the industry, combining precision, reliability, and ease of use. Thanks to the use of servo-controlled pumps, high-durability materials, and an advanced control system, the system is capable of meeting the most demanding market requirements, ensuring high performance and long system life.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!