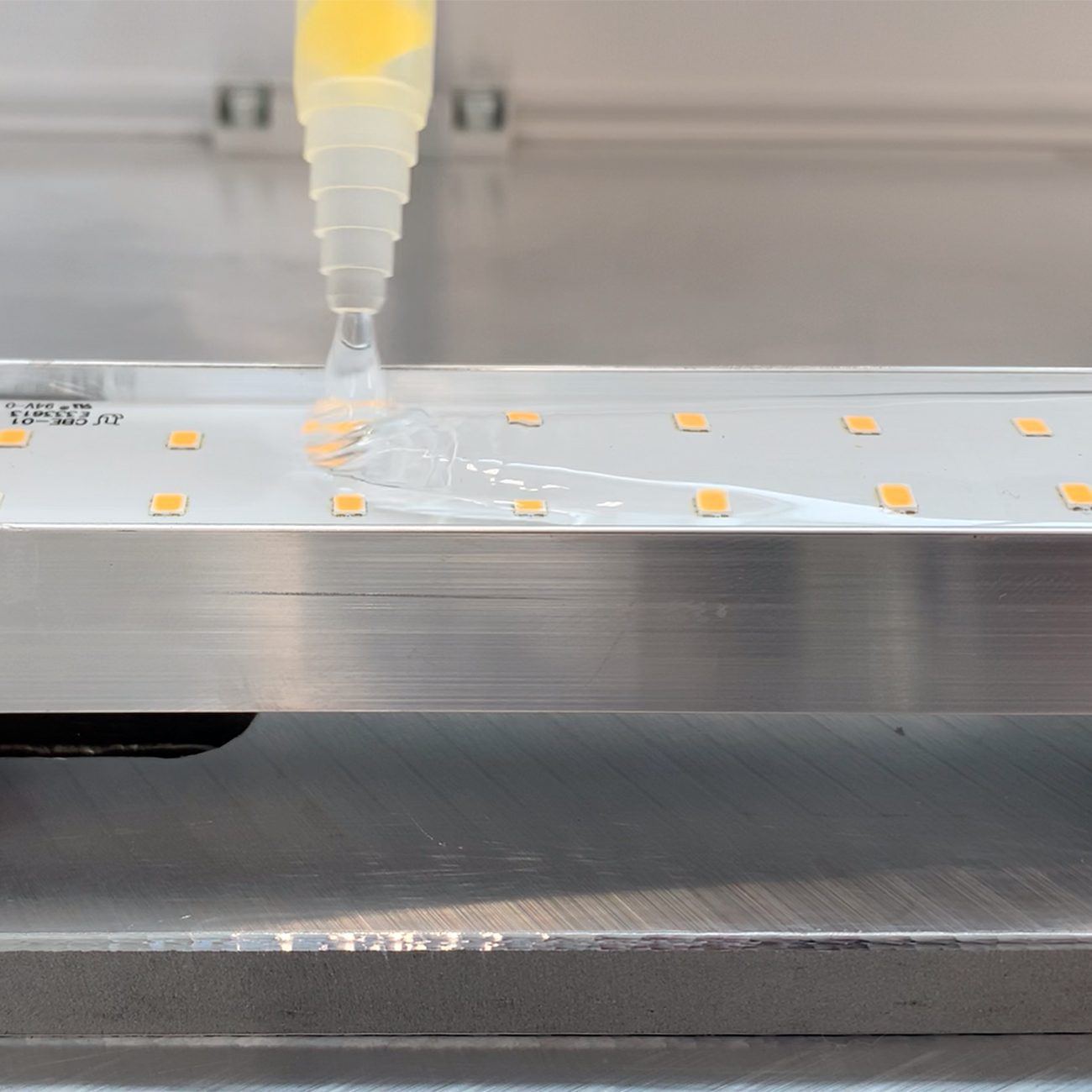

Elantas pu314 system for potting and encapsulation on led bars

Solution for volumetric dispensing of 2K resins in the electronics industry. Maximum versatility in the management of different quantities, resin flows, filling sequences, process control.

Characteristics

CASE STUDY

Volumetric Dispensing System for 2K Resins in the Electronics Sector

The customer required a solution for the volumetric dispensing of 2K resins in the electronics sector, which would offer maximum versatility in managing different quantities, resin flow rates, and filling sequences. The system needed to provide precise and complete control of the process, including flow rate management and prevention of air bubble formation.

01

Provided Solution

The system developed for the customer includes the following features and components:

Dispensing and Proportioning

Control of Quantity and Flow

The volumetric dispensing is adjustable via an operator panel, allowing the user to freely set the proportioning and flow rate of the resin and hardener. This offers great flexibility in managing various applications and dispensing volumes.

Handling and Process Management

Controlled Movement of Dispensing Head

The system features a dispensing head that can be adjusted to manage bars of different lengths, easily adapting to the various configurations of components.

Flow Rate and Feed Speed Control

The system’s flow rate and feed speed can be managed via the operator panel, ensuring precise and customizable control over the dispensing process.

Fluid Supply and Management

Direct Feeding from Original Containers

The resin and hardener are directly drawn from the original containers, eliminating the need for transfer and improving system efficiency. Fluid levels are monitored in real-time to prevent process interruptions.

Volumetric Pumps with Encoder

Volumetric pumps, equipped with encoders and closed-loop control, ensure precise and consistent dispensing without the formation of air bubbles.

Interface and Control

Operator Panel

The operator panel provides complete control over all system parameters, including proportioning, flow rate, and filling sequences. It is integrated according to Industry 4.0 standards to ensure compatibility with advanced management systems.

Capacitive Start Button

The capacitive start button, with a multicolored status indicator light, provides a simple and intuitive interface for starting and monitoring the dispensing process.

Precision and Repeatability

Bubble-Free Dispensing

The system is designed to ensure bubble-free dispensing, ensuring maximum precision and repeatability in the dispensing process.

02

System Benefits

- Flexibility and Versatility: The ability to freely adjust the proportioning and flow rate allows the system to adapt to a wide range of applications and dispensing requirements.

- Operational Efficiency: Direct feeding from the original containers and real-time fluid level monitoring optimize the process, reducing downtime and improving overall efficiency.

- Precision and Reliability: The volumetric pumps with encoders and the bubble-free dispensing management ensure precise and reliable dispensing.

- Advanced Control: The operator panel and integrated Industry 4.0 functionality offer detailed control and easy integration with production management systems.

In conclusion, the volumetric dispensing system for 2K resins developed for the electronics sector met the customer’s requirements for versatility and control. With precise dispensing parameter management, direct feeding from original containers, and advanced control via the HMI panel, the system improved process efficiency and ensured maximum precision and reliability in resin dispensing.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!