Loctite SI5615 High Viscosity Paste dispensing System

Manual bonding system designed for volumetric dispensing of high-viscosity, 2K adhesives.

Characteristics

CASE STUDY

Manual Adhesive Bonding System for 2K Adhesives

The customer required a manual bonding system designed for the volumetric dispensing of high-viscosity 2K adhesives. The goal was to achieve precise control over the volumes of adhesive and hardener, with the ability to manage parameters and programs via an HMI panel. Additionally, customized integrated equipment was needed for the manual filling of 2K cartridges.

01

Provided Solution

The system designed and implemented for the customer includes the following features and components:

Fluid Management

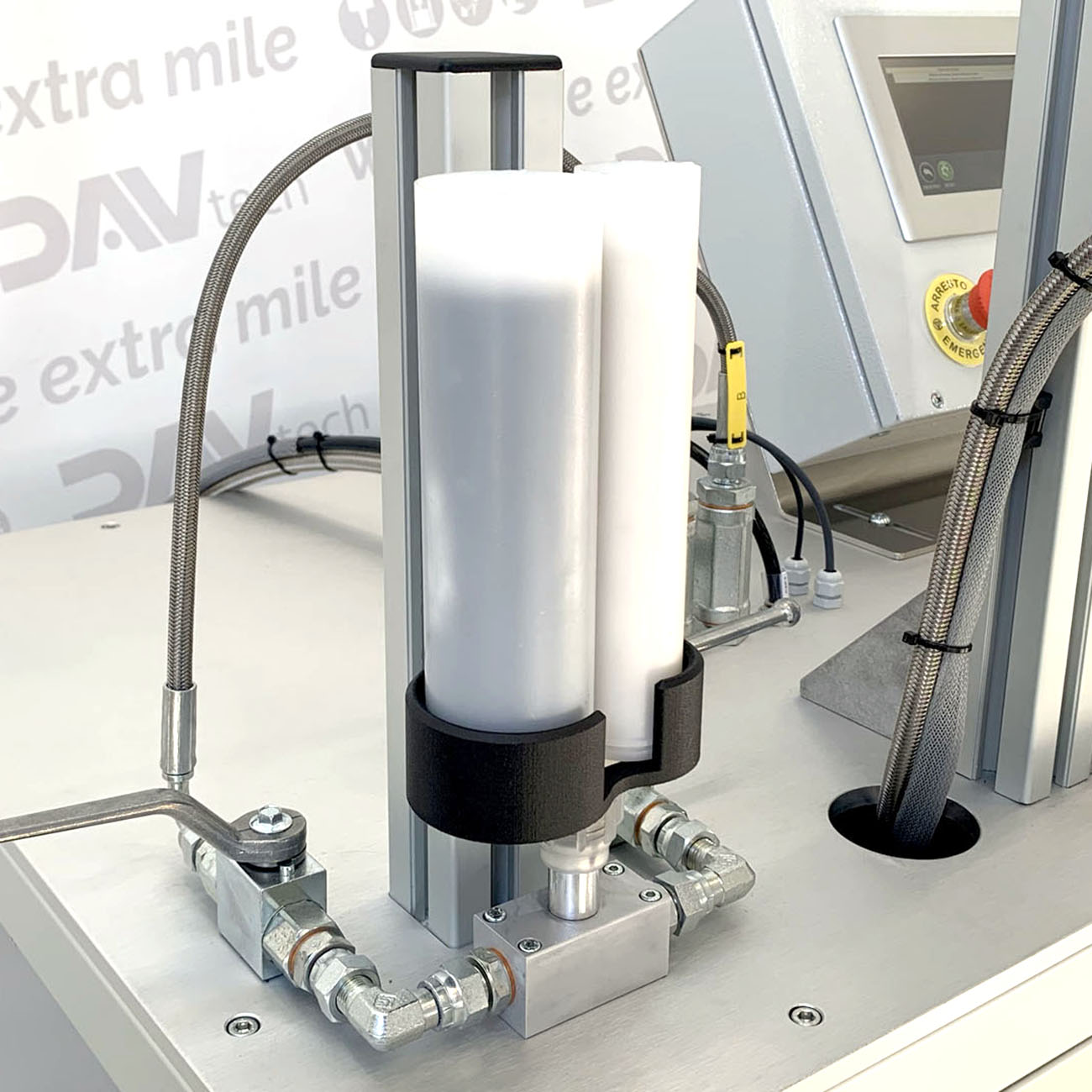

PP50 Pressure Plate Pumps

Used to manage the 2K adhesive, the pressure plate pumps ensure a constant and controlled flow of the high-viscosity fluid.

GP Gear Volumetric Pumps

Used for the hardener, the gear volumetric pumps ensure precise and uniform dispensing of the secondary component.

Parameterization and Control

Level Sensors

The system is equipped with sensors to monitor the levels of resin and hardener. These sensors allow for accurate and timely management of filling and dispensing, preventing process interruptions.

HMI Panel

The color HMI panel allows for the management of dispensing values, program selection, and creation of new programs. This intuitive interface helps the operator in adjusting and monitoring dispensing parameters.

Equipment and Customization

Customized Manual Equipment

The system includes integrated, customized equipment for the manual filling of 2K cartridges. This equipment is designed to optimize the filling process and ensure consistent quality of the finished product.

02

System Benefits

- Precision and Reliability: The combined use of pressure plate pumps and gear volumetric pumps ensures precise and reliable dispensing of adhesives and hardeners, improving the quality and consistency of the bonding process.

- Advanced Control: The HMI panel and level sensors provide detailed, real-time control over dispensing parameters and fluid levels, reducing the risk of errors and optimizing the production process.

- Operational Flexibility: The ability to create and manage new programs via the HMI panel allows the system to be easily adapted to various production and application needs.

- Filling Efficiency: The customized equipment for manual cartridge filling simplifies the process and reduces work time, improving overall efficiency.

In conclusion, the manual bonding system designed for the volumetric dispensing of high-viscosity 2K adhesives fully met the customer’s needs. With precise fluid management, advanced parameter control, and customized manual equipment, the system enhanced the quality of the bonding process and optimized operational efficiency.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!