Loctite anaerobic glue greasing and bonding system – Klueber

Automatic system for simultaneous dispensing of volumetric Grease and anaerobic glue:

• Fully pneumatic process management – with the exception of the motor dedicated to component rotation and control sensors

• Possibility of independent manual purging of volumetric grease and anaerobic glue.

• Nozzle, loader and sheeter tooling for easy management of different diameters.

Characteristics

CASE STUDY

Automatic Simultaneous dispensing System for Grease and Anaerobic Adhesive

The customer required an automatic system capable of simultaneously dispensing volumetric grease and anaerobic adhesive on mechanical components, with a fully pneumatic process managed by a combination of advanced mechanics and sensor technology. The system needed to ensure effective management of different diameters, facilitate manual component loading, and allow independent purging of the two fluids to guarantee process quality.

01

Provided Solution

The system designed and implemented to meet the customer’s needs includes the following features and components:

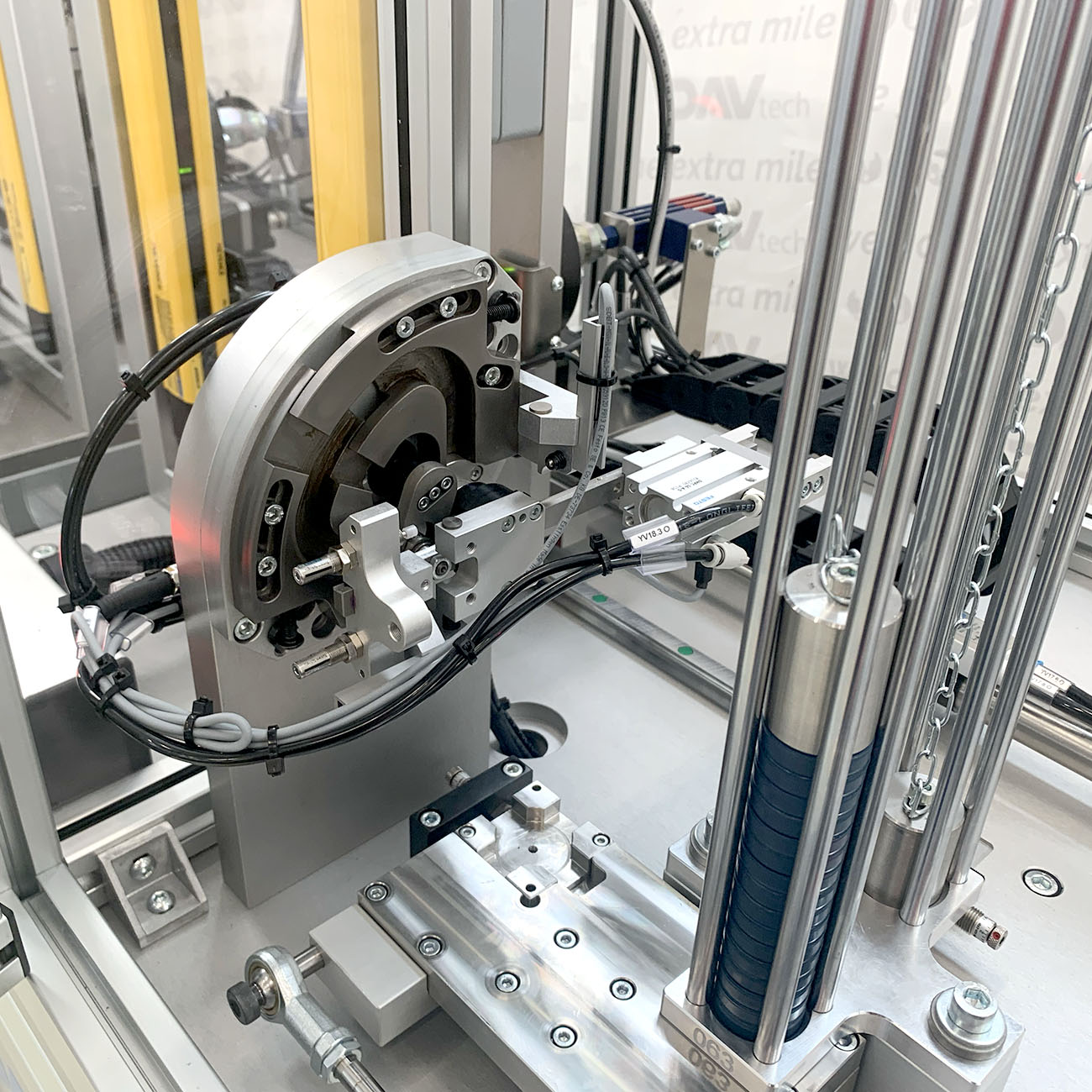

Pneumatic Management and Motorization

Fully Pneumatic System

The process is entirely pneumatic, except for the motor dedicated to rotating the component and the control sensors. This approach enables smooth and precise operation, combining mechanics and dispensing.

Motor for Component Rotation

A dedicated motor controls the rotation of the component, ensuring uniform distribution of the fluids.

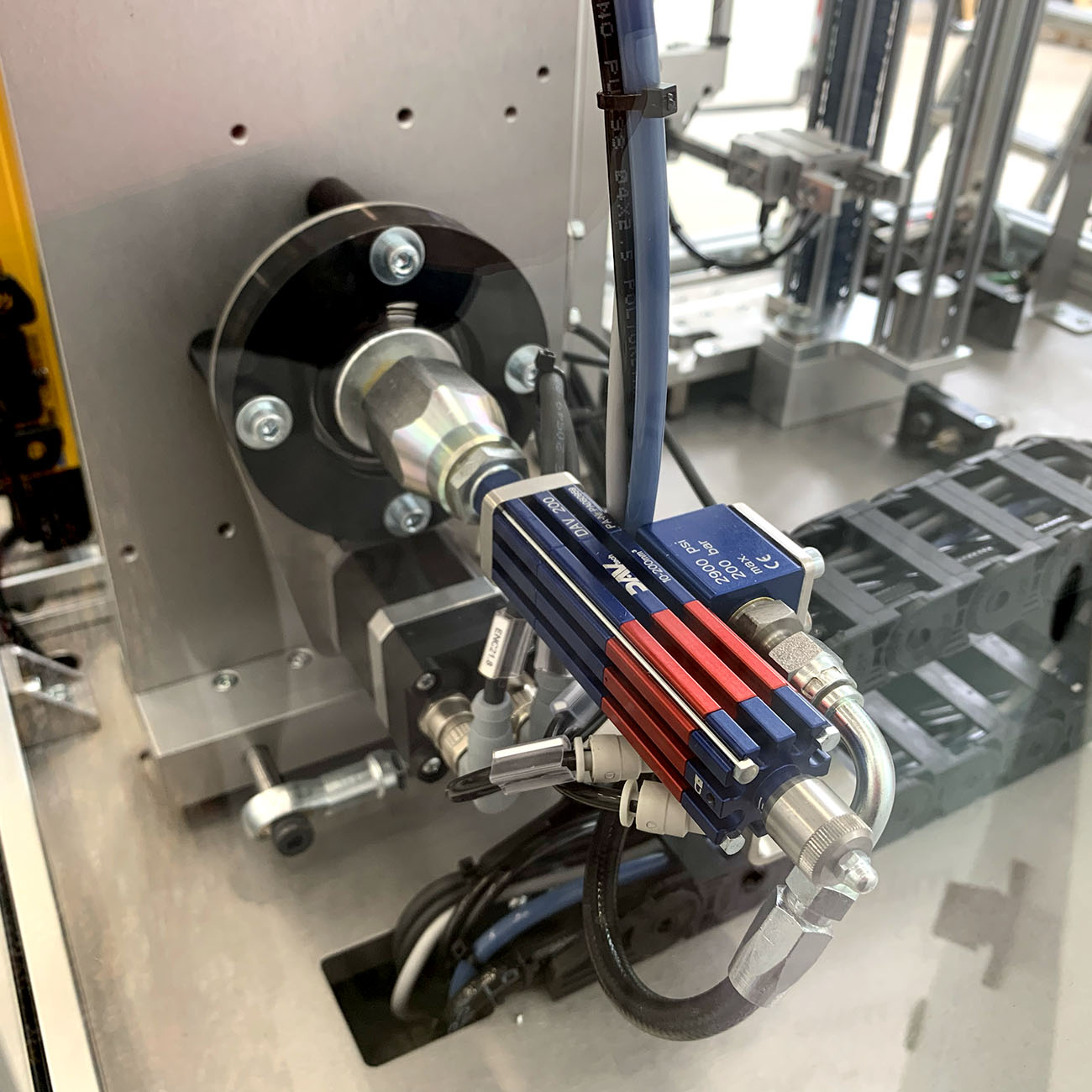

Purging and Tooling

Manual Purging

The system allows independent manual purging for both the volumetric grease and the anaerobic adhesive, simplifying process control and maintenance.

Tooling and Diameter Management

The system is equipped with tools for nozzles, feeders, and peelers, allowing for easy handling of different diameters. Consumable replacement and tooling can be done without difficulty

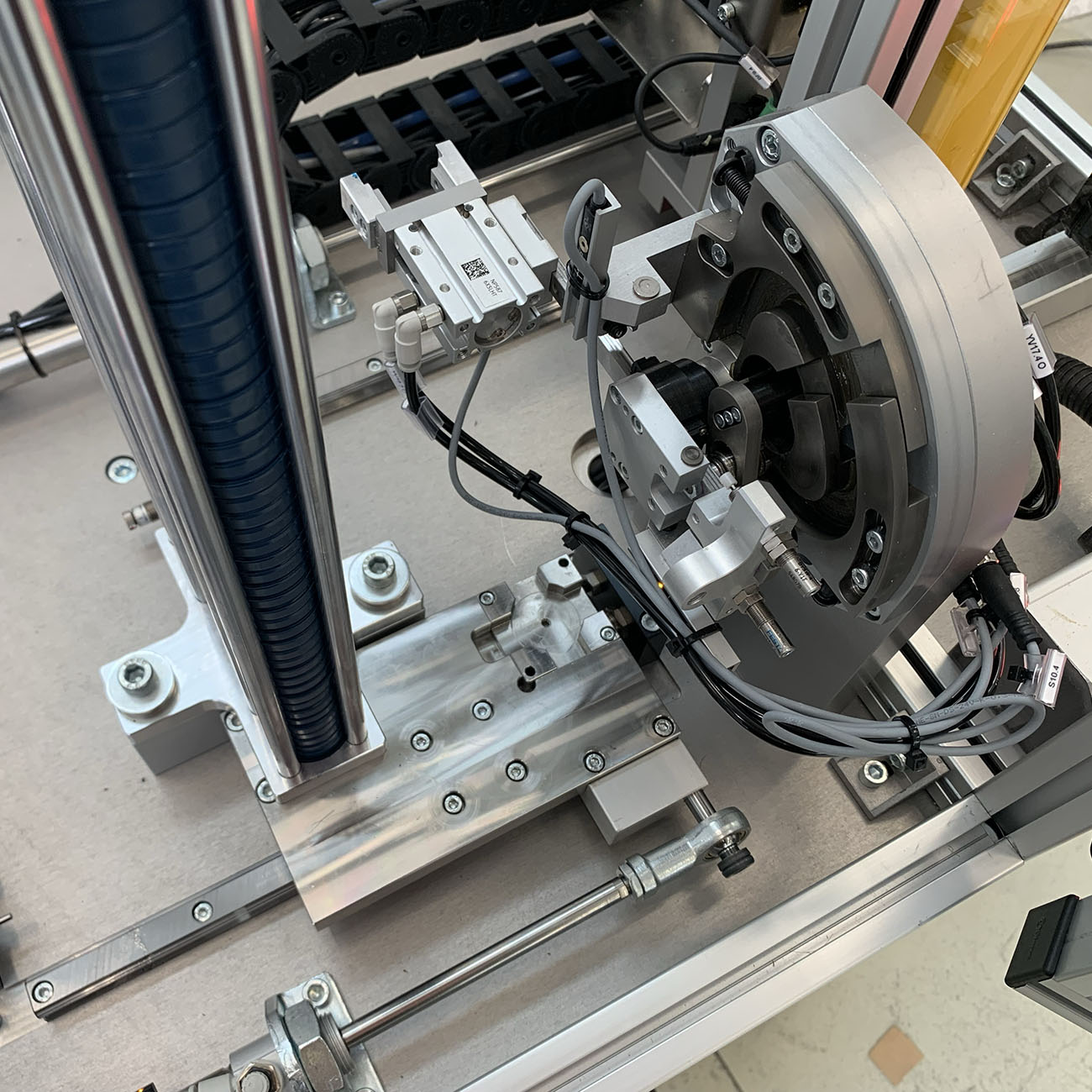

Loading and Sensing

Manual Loading

Components can be manually loaded through a dedicated tool and top window, simplifying access and management.

Advanced Sensing

A series of sensors detect the presence and correct positioning of the components, ensuring that the dispensing process occurs without errors.

Dispensing Process and Configuration

Simultaneous dispensing

The system enables the simultaneous dispensing of volumetric grease (internal) and anaerobic adhesive (external) onto the component, optimizing production time and improving efficiency.

Customized Nozzle Tooling

The nozzle is designed to serve as both a dispensing nozzle for internal radial grease dispensing and a rotation and insertion tool for the component. This versatile design simplifies the operation and reduces the need for complex tooling.

Mirror Tooling System

Mirror Tooling

Two mirror-image tools were developed to allow the processing of the component and a central assembly line for operators. This design enables a continuous flow and efficient component management.

02

System Benefits

- Efficiency and Precision: The combination of simultaneous dispensing and pneumatic management ensures precise, uninterrupted application of grease and adhesive, reducing cycle times and improving the quality of the final product.

- Flexibility and Ease of Maintenance: The system allows for managing different diameters through simple tooling and maintenance via manual purging. This increases operational flexibility and reduces downtime.

- Integration and Automation: The integration of the rotation system and the mirror-image tooling design optimize workflow and assembly line efficiency, making the production process management more straightforward.

- Monitoring and Control: The advanced sensors and the ability to detect the presence and positioning of components ensure accurate control and consistent quality throughout the dispensing process.

In conclusion, the automatic simultaneous dispensing system for grease and anaerobic adhesive provided the customer with a highly efficient and versatile solution, enhancing the precision and efficiency of the production process. With the ability to manage different diameters, a compact design, and advanced pneumatic management, the system fully met the customer’s production needs while ensuring high quality and reliability.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!