Grease Damping System

Robotic bench for dispensing grease damping on mechanical components.

Characteristics

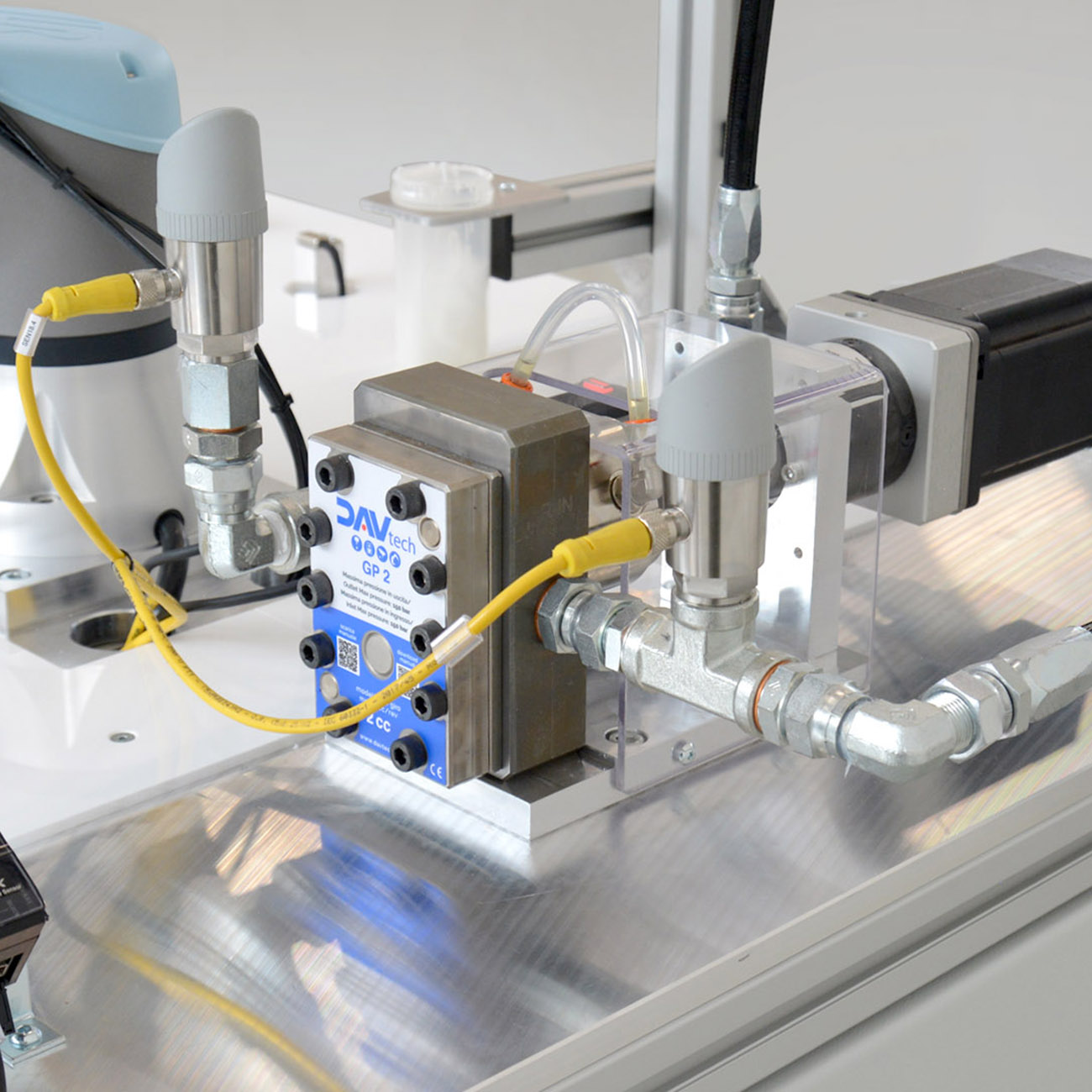

• Accurate dispensing with DAV Tech GP volumetric pump

• Collaborative robot with development of safety system for the operator

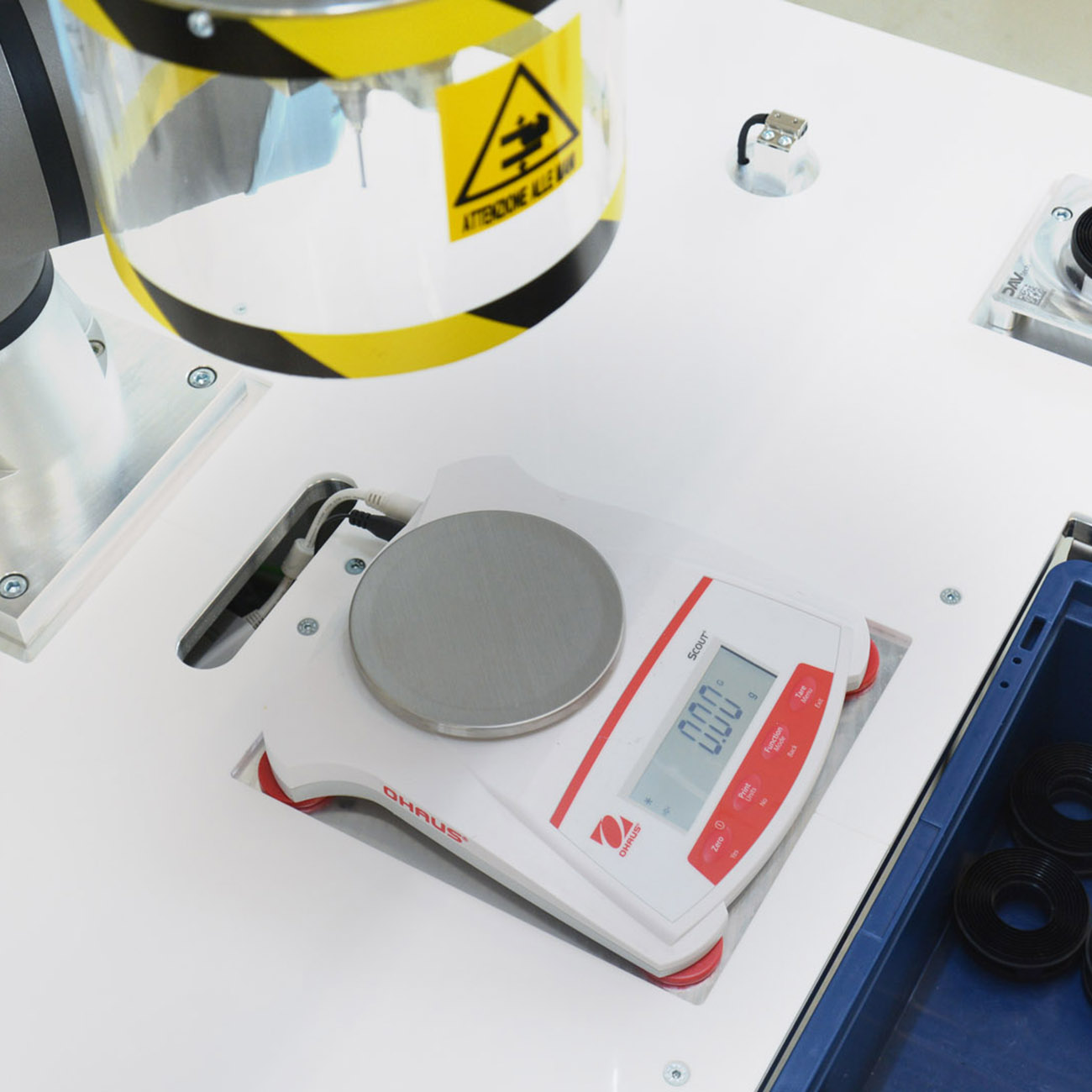

• Automatic weighing at the beginning of the shift and in frequency (adjustable)

• Automatic machine setup after data-matrix reading of the placements

• Interfacing with corporate MES from an Industry 4.0 perspective

• Master cycle: at the beginning of production, the weight of the grease dispensed is automatically detected to check the status of the system.

The control is then requested every X pieces (programmable).

CASE STUDY

Robotic Workstation for Damping Grease dispensing on Mechanical Components

The customer required an advanced and automated solution for dispensing damping grease on mechanical components. The objective was to ensure precise and uniform application of the grease, improve operator safety, and integrate the system with the company network for optimal control and traceability. It was also crucial to have a solution that allowed automatic weighing and rapid machine setup.

01

Provided Solution

To meet the customer’s requirements, we designed and built a robotic workstation for damping grease dispensing with the following key features:

Accurate and Controlled dispensing

DAV Tech GP Volumetric Pump

The workstation uses a DAV Tech GP volumetric pump to ensure precise and consistent dispensing of damping grease on the mechanical components. The volumetric pump was selected for its reliability and accuracy in controlling the grease flow.

Automation and Safety

Collaborative Robot

The system is equipped with a collaborative robot that works closely with the operator, improving process efficiency and ensuring a safe working environment through the development of an advanced safety system.

Automatic Weighing

The workstation includes an automatic weighing system that measures the weight of the grease at the beginning of each shift and at programmable intervals. This control ensures that the amount of grease dispensed is always compliant with standards, improving quality and reducing waste.

Advanced Setup and Interfacing

Automatic Setup

After reading the data matrix of the parts, the system automatically performs the machine setup, reducing preparation time and ensuring quick adaptability to different types of components.

MES and Industry 4.0 Interfacing

The workstation is integrated with the company’s MES system, facilitating communication between the dispensing system and the production network. This interfacing supports process optimization and data collection in line with Industry 4.0 standards.

Process Control and Monitoring

Master Cycle and Programmable Control

At the start of production, the system automatically measures the weight of the dispensed grease to check the system’s status. Following this, control is carried out at programmable intervals, ensuring that each production cycle is monitored and the system operates correctly.

02

Results and Benefits

The robotic workstation for damping grease dispensing provided significant benefits to the customer:

- Precision and Reliability: The volumetric pump and automatic weighing system ensured precise and consistent dispensing, improving product quality and reducing grease waste.

- Efficiency and Safety: The integration of the collaborative robot and safety system optimized the production process and ensured a safe working environment for the operator.

- Automation and Ease of Use: The automatic setup and MES interfacing simplified machine management, improving operational efficiency, reducing preparation time, and increasing productivity.

- Monitoring and Control: The master cycle and programmable control ensured the system operated within the desired parameters, providing continuous monitoring and accurate process traceability.

The robotic workstation fully met the customer’s needs, offering an advanced solution for damping grease dispensing with significant improvements in precision, efficiency, and technological integration.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!