2K bonding system

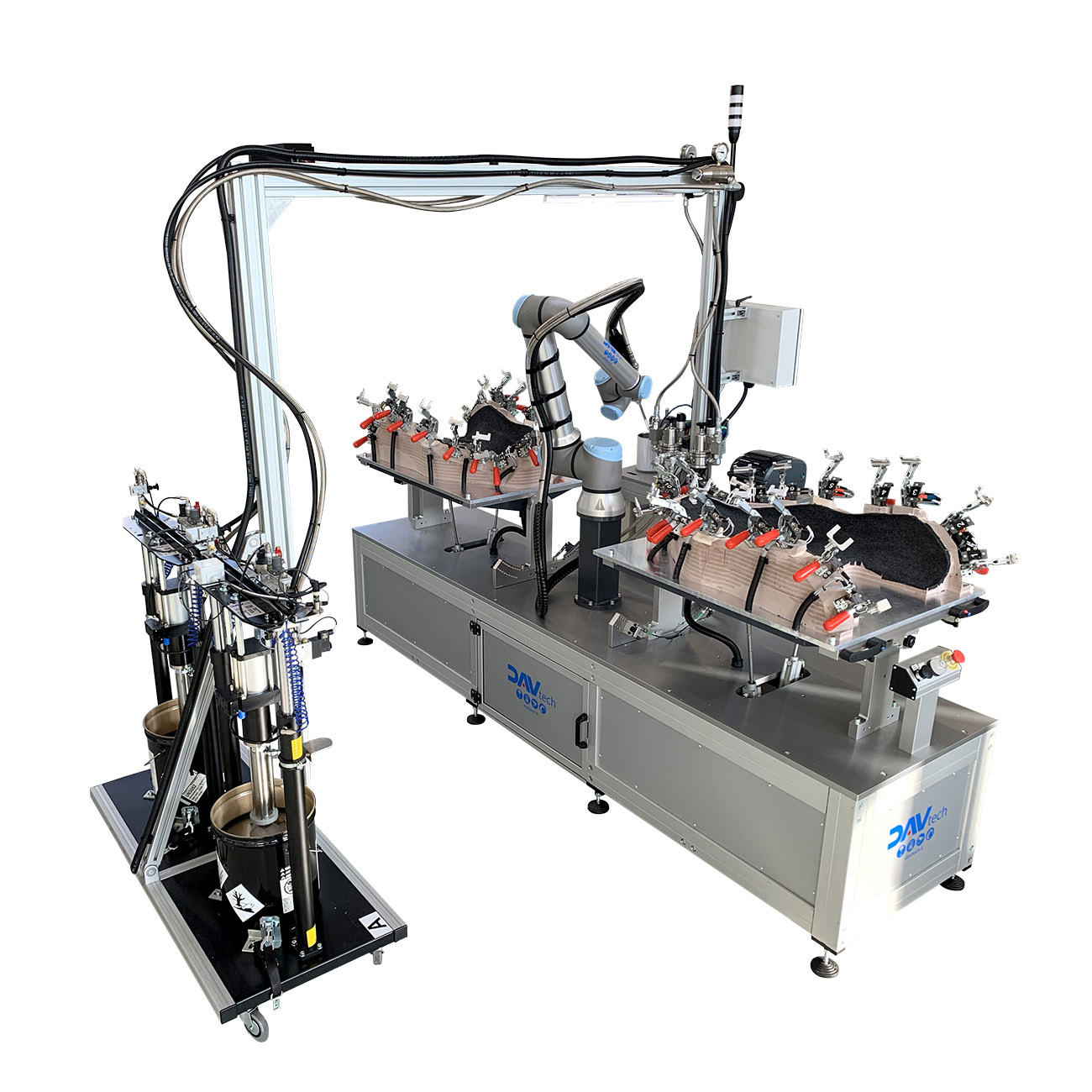

Robotic system for 2K bonding of automotive seat components.

Collaborative dispensing system for chromins seat, 2K bonding using a dispensing and proportioning system.

Characteristics

CASE STUDY

Robotic System for Bi-Component Adhesive Bonding of Automotive Seat Components

The customer needed an advanced robotic system for the bi-component adhesive bonding of chrome parts on automotive seats. The goal was to improve the efficiency and precision of the bonding process by integrating a dispensing and proportioning system that was collaborative and highly automated. The system had to be equipped with tools for process and information management, such as displays, QR code readers, and label printers.

01

Provided Solution

We developed a complete robotic solution for bonding chrome parts on automotive seats, including:

Collaborative Dispensing and Bonding System

Dispensing and Proportioning

The system uses a PDP 1000 volumetric pump and pressure plate pumps to ensure precise and consistent dispensing of bi-component materials. This ensures a uniform and high-quality application of the chrome parts on the seats.

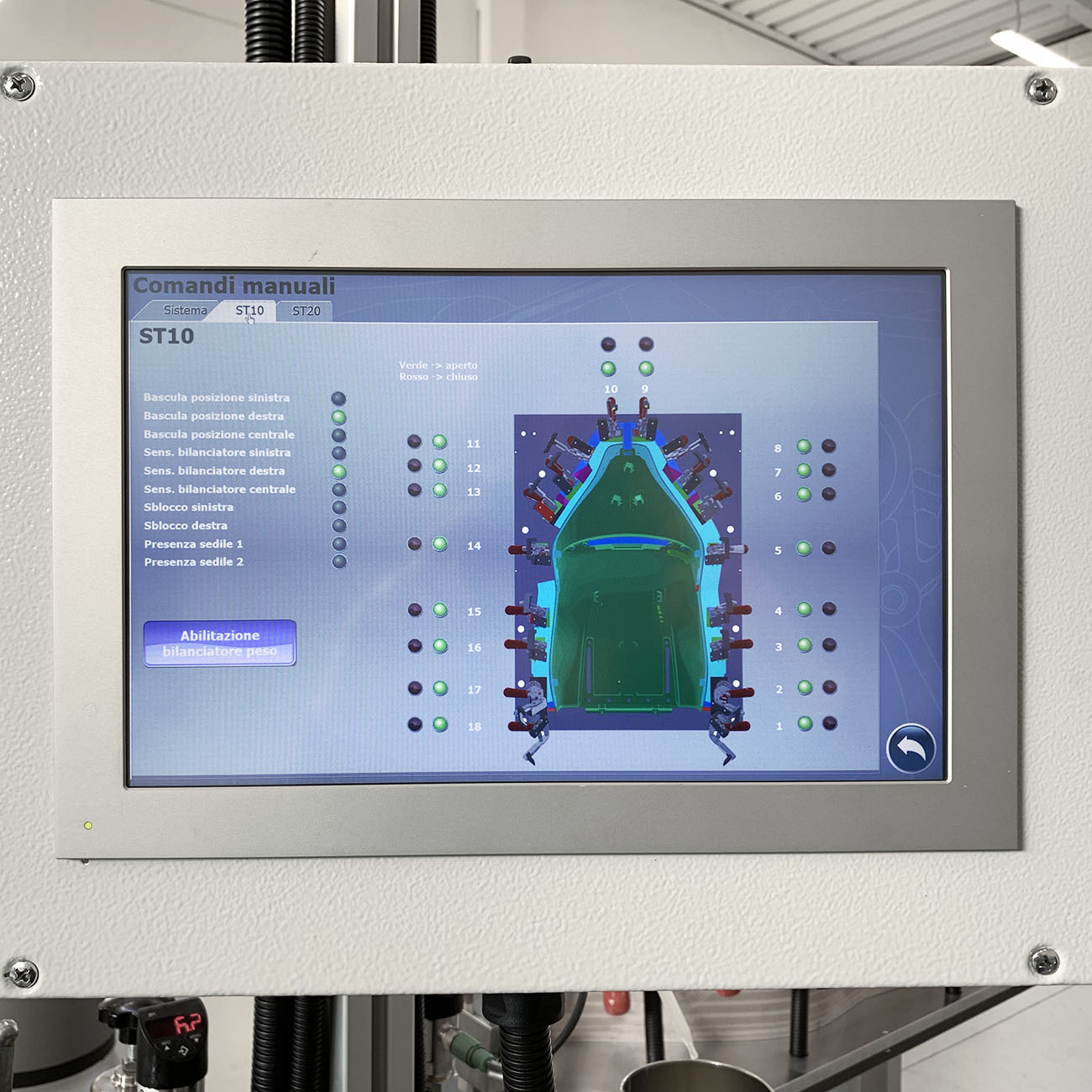

Position Sensors

Tilt sensors were integrated to monitor the correct position of components during the bonding process, improving accuracy and reducing errors.

Process Management and Control

HMI Display

An HMI display allows intuitive, real-time management of the bonding process, with the ability to monitor and modify operating parameters directly from the control panel.

Integrated Label Printer

For complete traceability, the system includes an integrated label printer that prints labels directly on the components or finished products.

QR Code Reader

A QR code reader is used to identify and track components, facilitating information management and improving material traceability.

Functionality and Safety

Assisted Handling Cylinders

The cylinders assist in handling components, reducing the operator’s workload and improving process efficiency.

Dual Unlock Button for Balancer

A balancer unlock system on the handle, activated by a dual button, ensures operational safety during the process.

Pushbutton Panel and Signal Light

The pushbutton panel, equipped with a capacitive button for starting the system and a signal light, provides visual and auditory feedback on the system’s status and ongoing operations.

02

Results and Benefits

The robotic system for bi-component adhesive bonding provided numerous benefits to the customer:

- Precision and Reliability: The combination of volumetric pumps and position sensors ensured precise and accurate dispensing and application of materials, improving the quality and consistency of the final product.

- Automation and Efficiency: The integration of tools such as the HMI display, label printer, and QR code reader automated and optimized the production process, reducing work time and increasing productivity.

- Safety and Ease of Use: Safety features, such as the dual unlock button and assisted handling cylinders, ensured a safe and user-friendly working environment.

- Complete Traceability: The ability to print labels and track components via QR codes improved information management and process traceability.

The robotic system provided an advanced and highly automated solution for bi-component adhesive bonding of automotive seat components, effectively meeting the customer’s needs and enhancing the quality and efficiency of the production process.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!