Loctite/Loxeal Cyan-Acrylic Bonding System

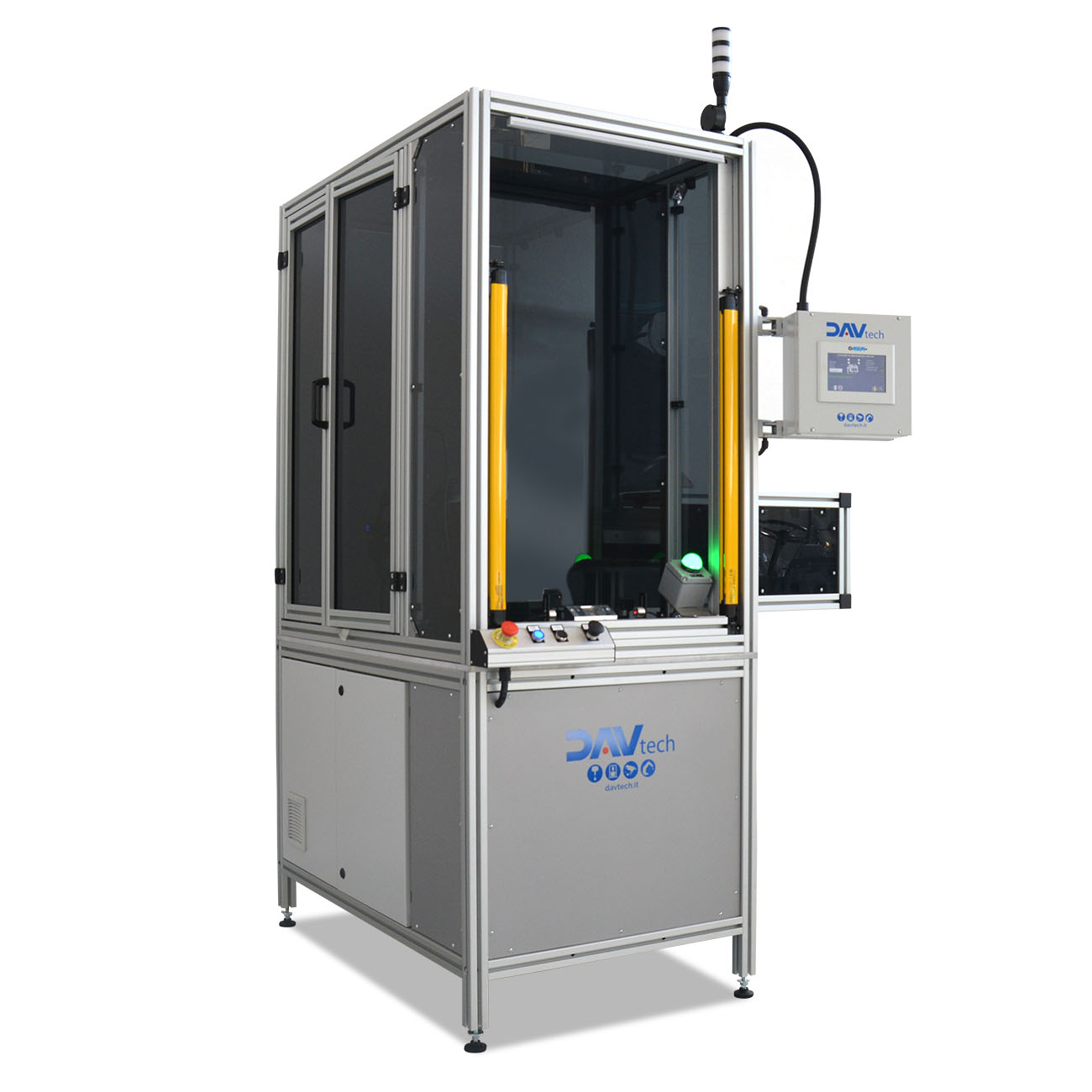

Semi-automatic cell for gluing with cyano-acrylic glue, vision system with LumiTrax technology and piece unloading.

Characteristics

CASE STUDY

Semi-Automatic Cell for Cyanoacrylate Adhesive Bonding

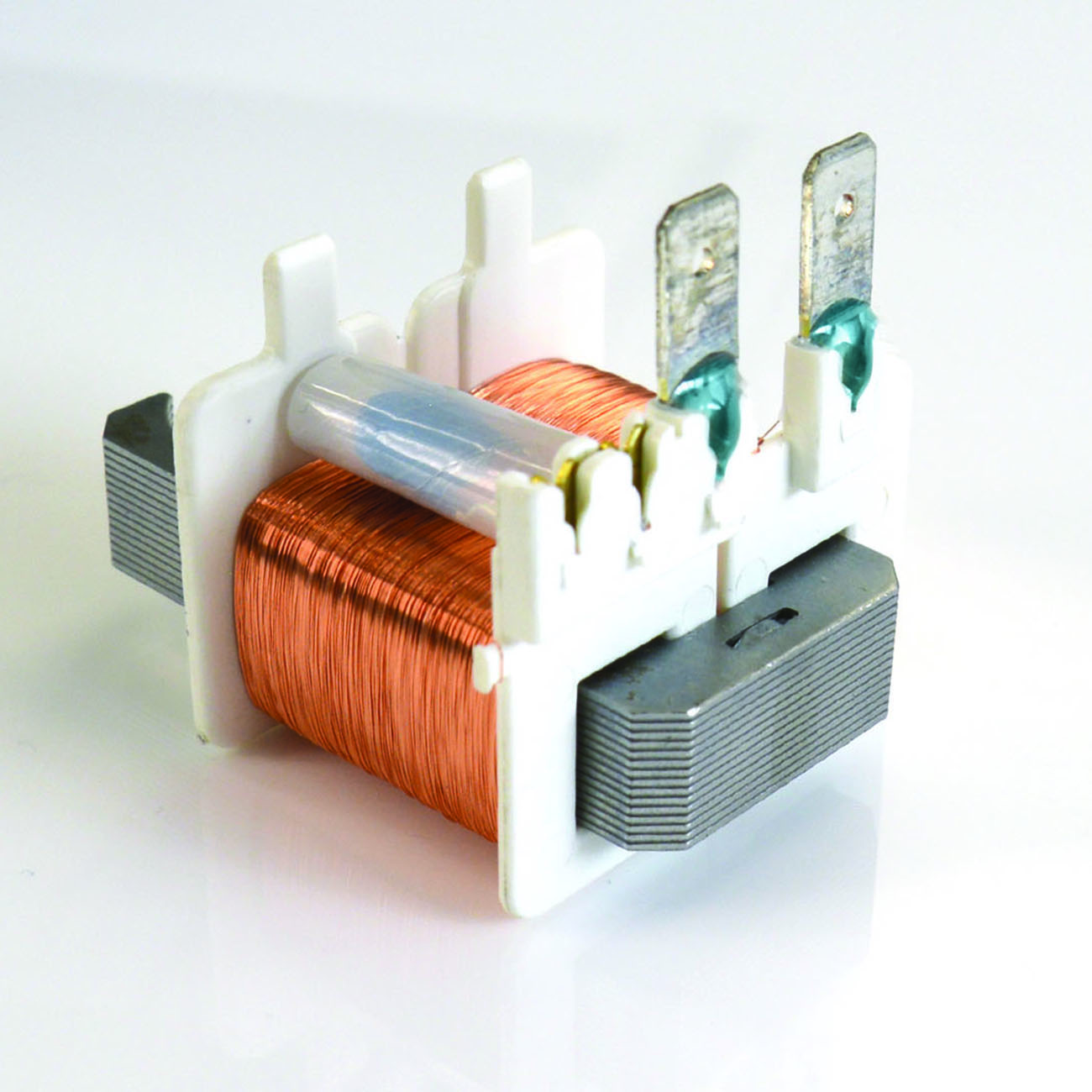

The customer required a semi-automatic cell for bonding small components using cyanoacrylate adhesive. The request included the ability to precisely dispense on two fastons simultaneously, quality control of the dispensing process through an advanced vision system, and efficient management of the production cycle with part unloading. Additionally, an operator panel for complete process parameter management and a dispensing rate of one part every 6 seconds were essential.

01

Provided Solution

We designed and built a semi-automatic cell with the following features:

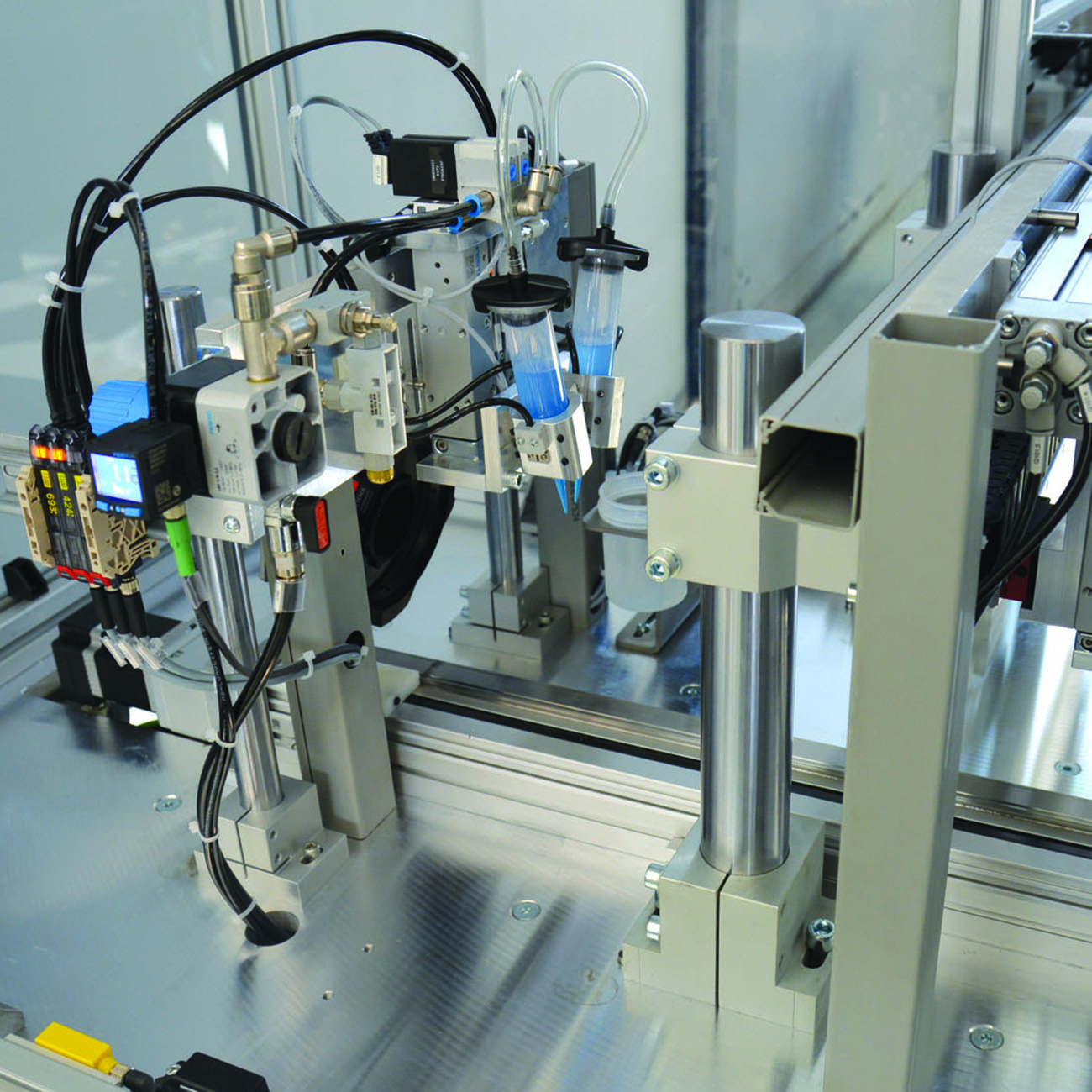

Precise and Simultaneous Dispensing

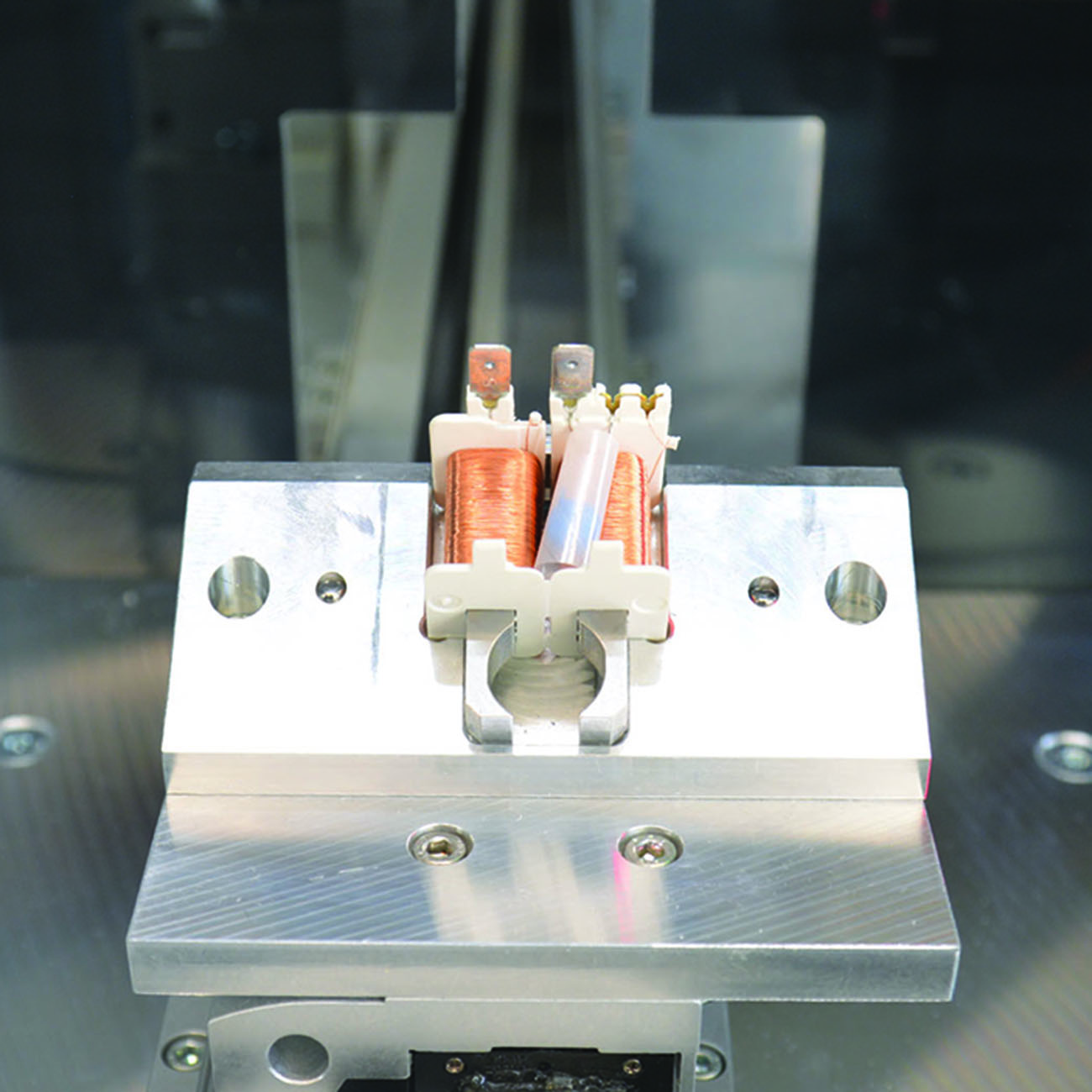

Dispensing on 2 Fastons

The cell is equipped to simultaneously dispense 0.03 cc of cyanoacrylate adhesive on two fastons. This feature allows for rapid and precise dispensing, optimizing the bonding process.

Dispensing Control with Vision System

LumiTrax Technology

The dispensing control is carried out via an advanced LumiTrax vision system. This system uses a multi-spectral illuminator to inspect and verify the quality and precision of the adhesive applied to the components.

Quality Verification

The LumiTrax technology ensures detailed and real-time control of the dispensing quality, identifying any anomalies and ensuring process consistency.

Parameter Management and Control

Operator Panel

A dedicated operator panel allows for complete management of the dispensing parameters and the bonding process. Operators can easily adjust settings and monitor the system status through an intuitive interface.

Efficiency and Production Rate

Fast Dispensing

The cell is designed to complete the dispensing of one part every 6 seconds, maintaining a high production rate and meeting the customer’s production needs.

Part Unloading

After dispensing, the parts are automatically unloaded, optimizing workflow and reducing downtime.

02

Results and Benefits

The provided system brought significant benefits to the customer’s bonding process:

- Dispensing Precision: The ability to dispense 0.03 cc of adhesive on two fastons simultaneously improved the quality and consistency of the bonding process.

- Advanced Quality Control: The LumiTrax vision system enabled detailed and real-time control, ensuring product compliance and reducing the risk of defects.

- Intuitive Management: The operator panel made it easy to adjust parameters and manage the process, enhancing operational efficiency.

- High Production Rate: The dispensing rate of one part every 6 seconds met the customer’s production needs, increasing productivity and efficiency.

This semi-automatic cell provided an effective and advanced solution for cyanoacrylate adhesive bonding, precisely addressing the customer’s needs and significantly improving production quality and efficiency.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!