Loctite 638 Magnet Bonding System

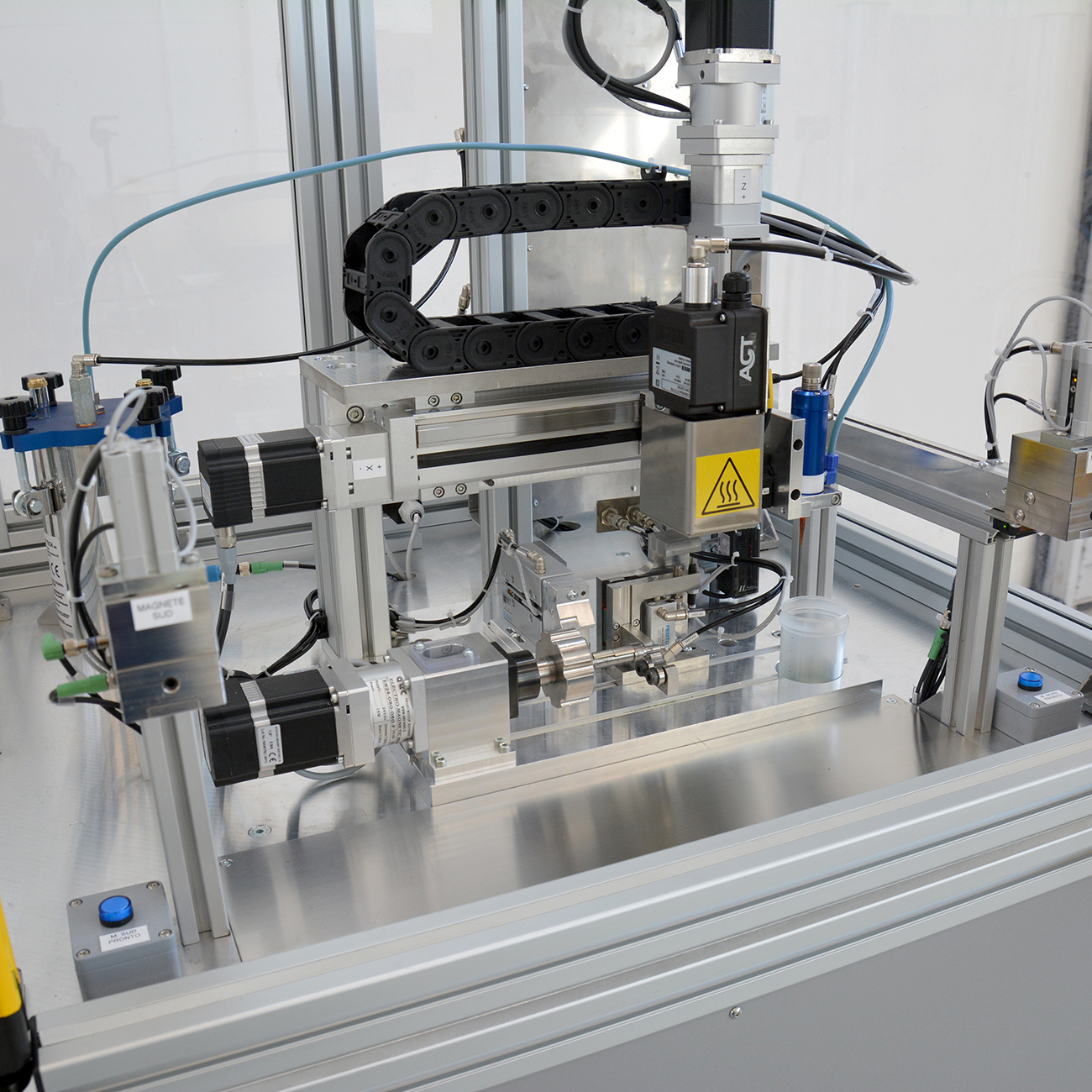

Robotic system with 3 + 1 interpolated axes for gluing and mounting magnets: automotive sector.

Characteristics

CASE STUDY

Robotic System for Adhesion and Assembly of Magnets in the Automotive Sector

The customer required an automated system for the fitting, adhesion, and assembly of magnets in the automotive sector. The system had to manage the precise quantity and positioning of the magnet dispensing, include an automatic peeling system, and ensure correct magnet placement via advanced sensors. Additionally, a solution was needed that included the control of heat shrink tubing heating.

01

Provided Solution

We designed and implemented an advanced robotic system with the following features:

3 + 1 Axes Interpolated Robotic System:

Interpolated Axes

The system uses a robot with 3 main axes and 1 additional axis for precise and versatile movement. This allows for detailed and accurate control of the fitting and assembly processes of the magnets.

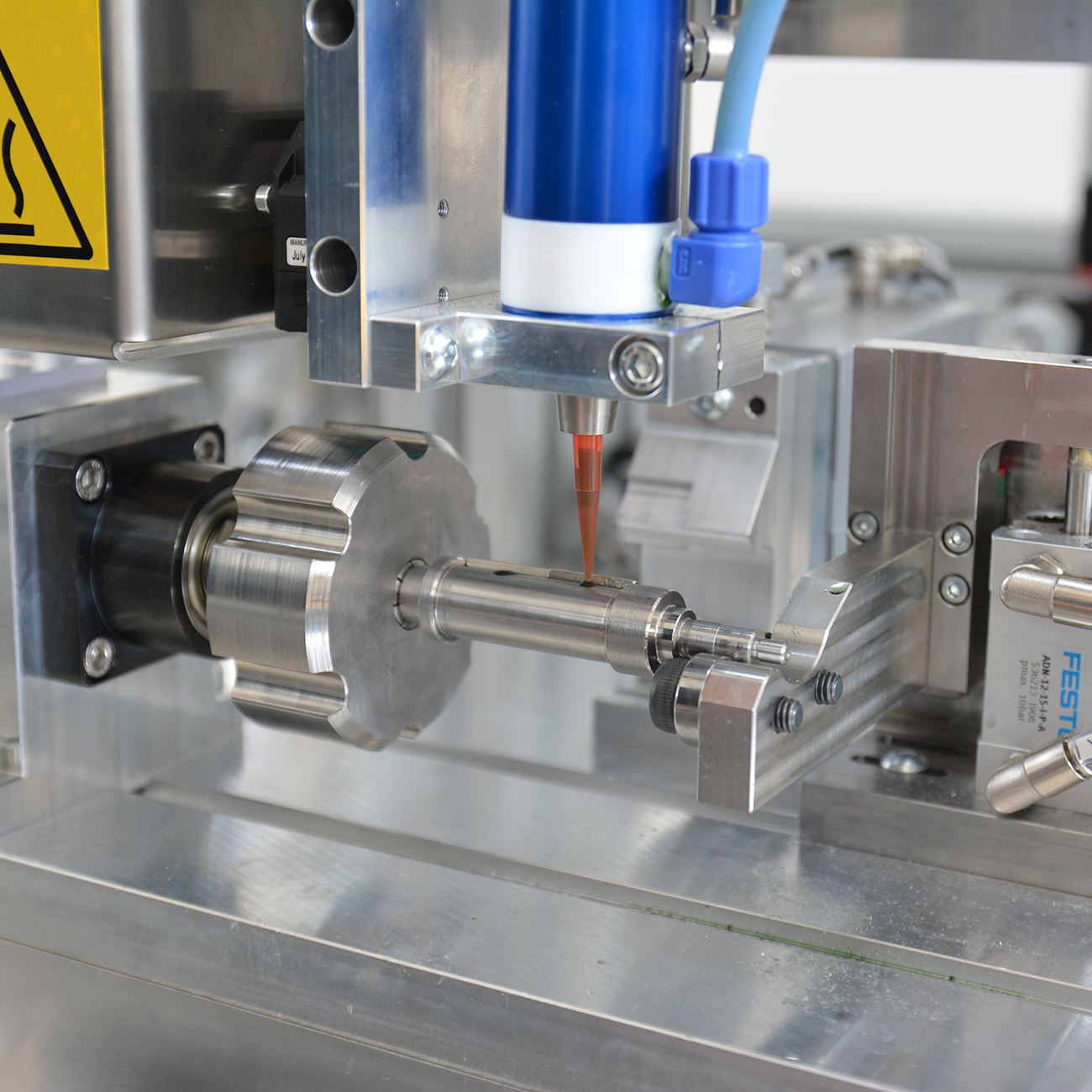

Quantity and Position Management

Precise Adjustment

The quantity and positioning of the magnet dispensing are fully adjustable, offering high flexibility and adaptability to specific production needs.

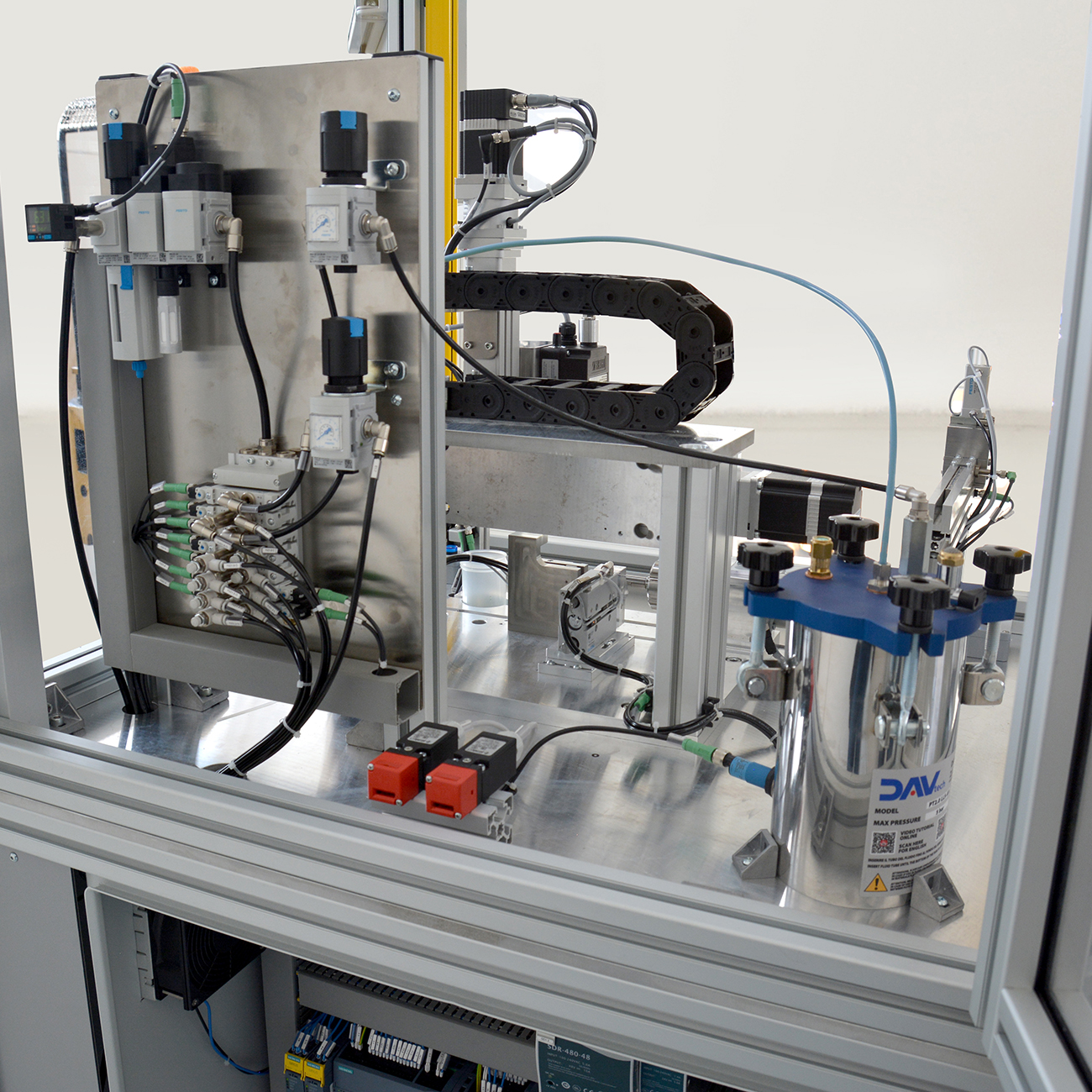

Automatic Magnet Peeling System

NORTH/SOUTH Peeling

The system integrates an automatic magnet peeling process, managed in a NORTH/SOUTH mode, to simplify and accelerate the magnet preparation operation.

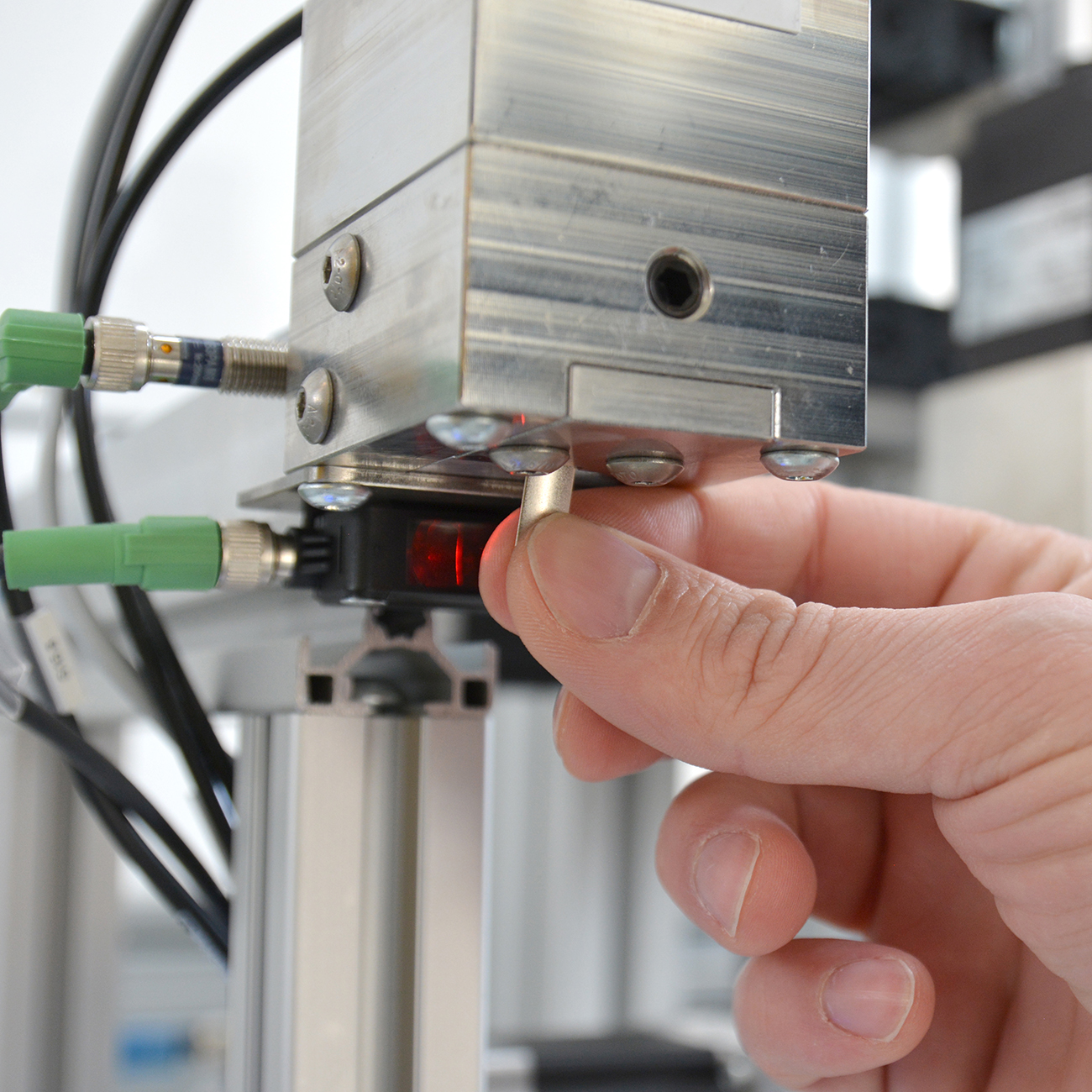

Placement Control with Laser Sensors

Laser Sensor

A laser sensor system is implemented to ensure the correct placement of the magnets during adhesion and assembly. This ensures the magnets are placed with millimetric precision, improving the quality of the final product.

Heating System for Heat Shrink Tubing

Temperature Control

The system is equipped with a controlled heating system for the heat shrink tubing, ensuring the temperature is maintained within optimal parameters for perfect adhesion and finish.

02

Results and Benefits

The provided robotic system transformed the magnet adhesion and assembly process, offering numerous benefits to the customer:

- High Precision: The combination of interpolated axes and laser sensors ensured extremely precise placement and dispensing, enhancing the quality and consistency of the product.

- Efficient Automation: The automatic peeling system and precise adjustment of quantity and positioning optimized the production process, reducing setup times and increasing efficiency.

- Advanced Control: The controlled heating system ensured an optimal finish for the heat shrink tubing, contributing to the durability and quality of the final product.

- Flexibility and Adaptability: The proposed solution offered great flexibility, easily adapting to different production needs and improving overall process efficiency.

This robotic system provided a complete and automated solution for magnet assembly, meeting the specific needs of the automotive sector and significantly improving productivity and production quality.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!