Paint coating system

Specific robotic system for the volumetric dispensing of protective paint on diamond cutting blades.

Characteristics

CASE STUDY

Robotic System for Volumetric Dispensing of Protective Paint on Diamond Blades

The customer required a robotic solution for volumetric dispensing of protective paint on diamond cutting blades. The primary objective was to ensure uniform paint application, prevent the inhalation of toxic substances, and provide precise process control under varying conditions of temperature, viscosity, and fluid pressure. Additionally, it was essential to have complete process control and accurate data recording.

01

Provided Solution

To meet the customer’s requirements, we designed and implemented an advanced robotic system with the following features:

Depressurized Cabin

Safe Working Environment

The cabin is designed to maintain a safe working environment, preventing the inhalation of toxic substances through controlled depressurization. This is crucial for protecting operator health and maintaining air quality within the cabin.

Nozzle and Dispensing

Custom Nozzle

Specifically designed for paint distribution on diamond blades, ensuring precise and uniform application.

Advanced Volumetric Dispensing

Using PCP progressive cavity volumetric pumps, the system ensures consistent dispensing unaffected by temperature, viscosity, and pressure variations, allowing for well-defined disc edges and even coating.

Positioning and Equipment

Adjustable Positioning

The positioning system is equipped with adjustable supports to accommodate varying disc sizes, enhancing the system’s flexibility.

Capacitive Start Button

Equipped with a multicolor indicator light to signal the process status, simplifying operation and monitoring.

Curing and Control System

Infrared Lamp

Used for curing the paint, with adjustable intensity to meet specific process requirements.

Laser System

For detecting the presence of the part, ensuring each disc is treated correctly.

Process Management and Data Management

Panel PC and Industry 4.0

The process is managed via an advanced Panel PC, which allows data storage on a company server. This ensures complete process traceability and compliance with Industry 4.0 standards.

Recipe Selection

The system allows recipe selection via barcode, QR code, or Data Matrix reader, simplifying configuration and changing painting specifications.

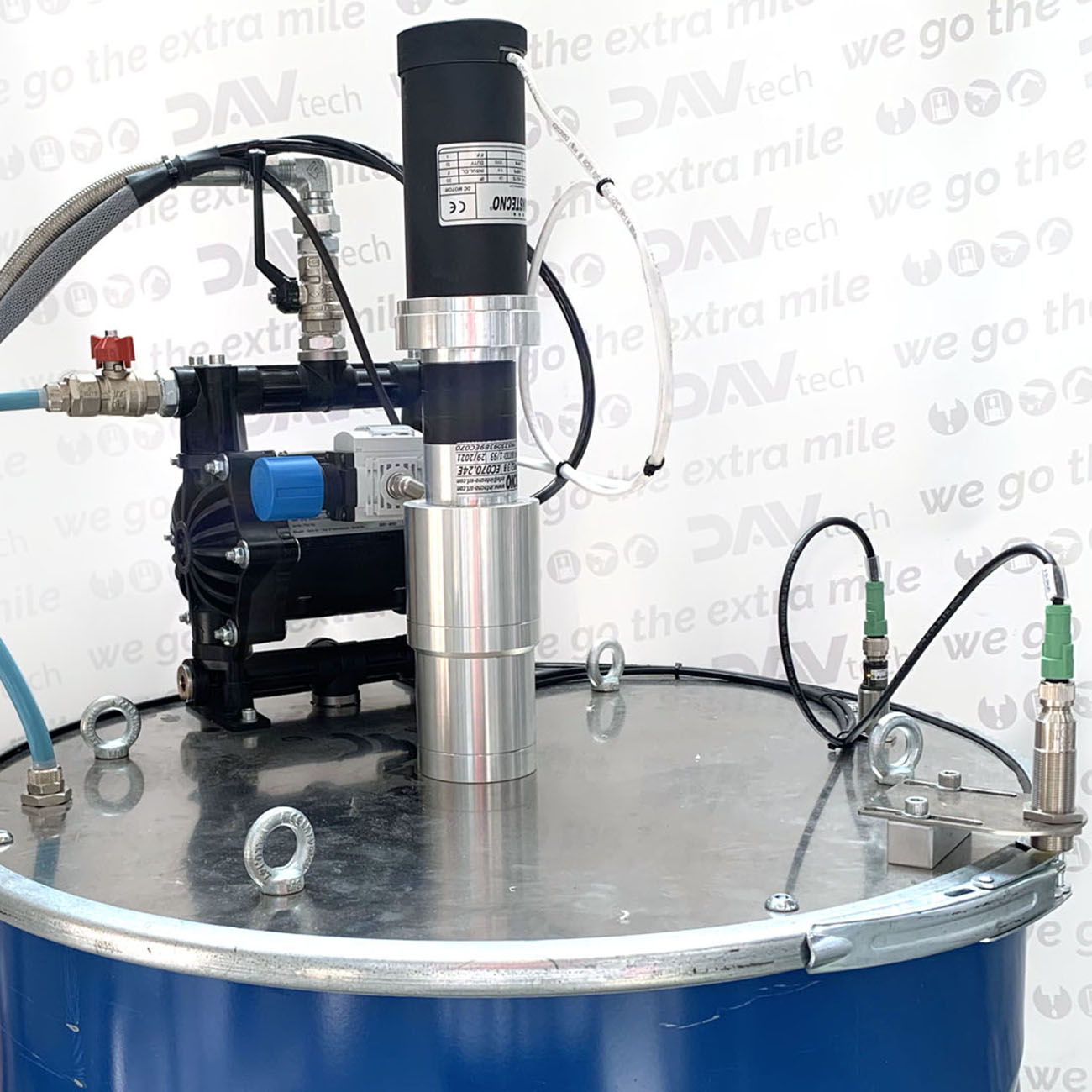

Feeding and Recirculation System

Original Drum Feeding

Includes a recirculation and mechanical agitator system to maintain the paint homogeneous and ready for use, preventing sedimentation and separation.

02

Results and Benefits

The robotic system provided fully met the customer’s needs, ensuring uniform and precise application of protective paint on the diamond blades. The depressurized cabin and part presence control system improved safety and operational efficiency.

The use of PCP volumetric pumps ensured reliable and consistent dispensing, while control via the Panel PC and data management in compliance with Industry 4.0 optimized process traceability and management. The infrared curing system and recipe selection via barcode reader further improved product quality and operational flexibility, making the system highly adaptable to different production needs.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!