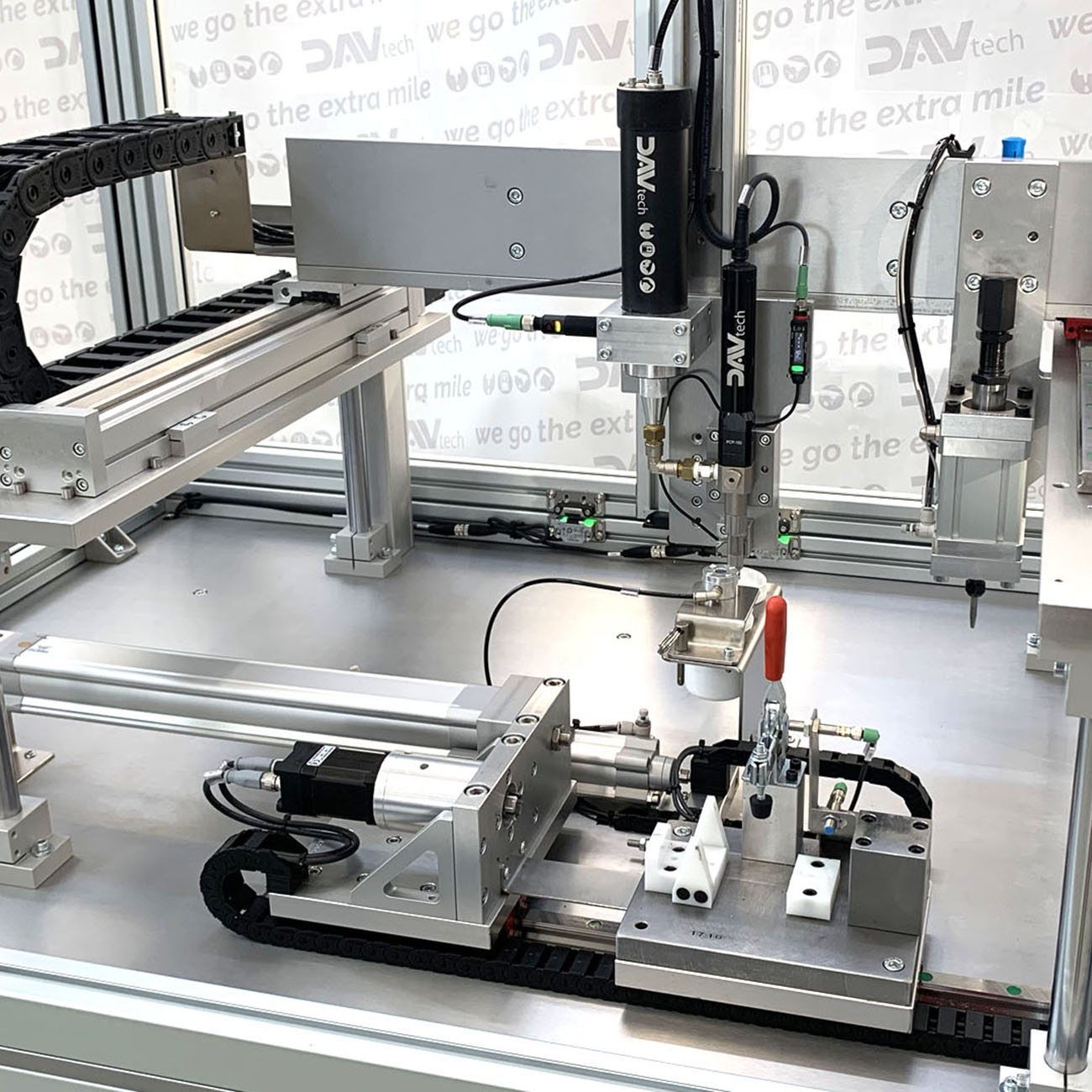

Threebond 1207 volumetric sealing system

Controlled sealing and assembly of automotive components, with laser control and marking systems to highlight the conformity of the operations carried out.

Characteristics

CASE STUDY

Controlled Sealing and Mounting System for Automotive Components

The customer needed an advanced system for sealing and mounting automotive components, with a focus on precision operations and the quality of the final product. The system had to ensure controlled sealing of different components, with monitoring and marking to confirm compliance of operations. It was critical that the system handled sealant dispensing without external influences such as temperature and pressure, and that it included quality controls to ensure process reliability.

01

Solution Provided

We have developed a sealing and assembly station that perfectly meets the customer’s needs:

Precise Sealing and Dispensing

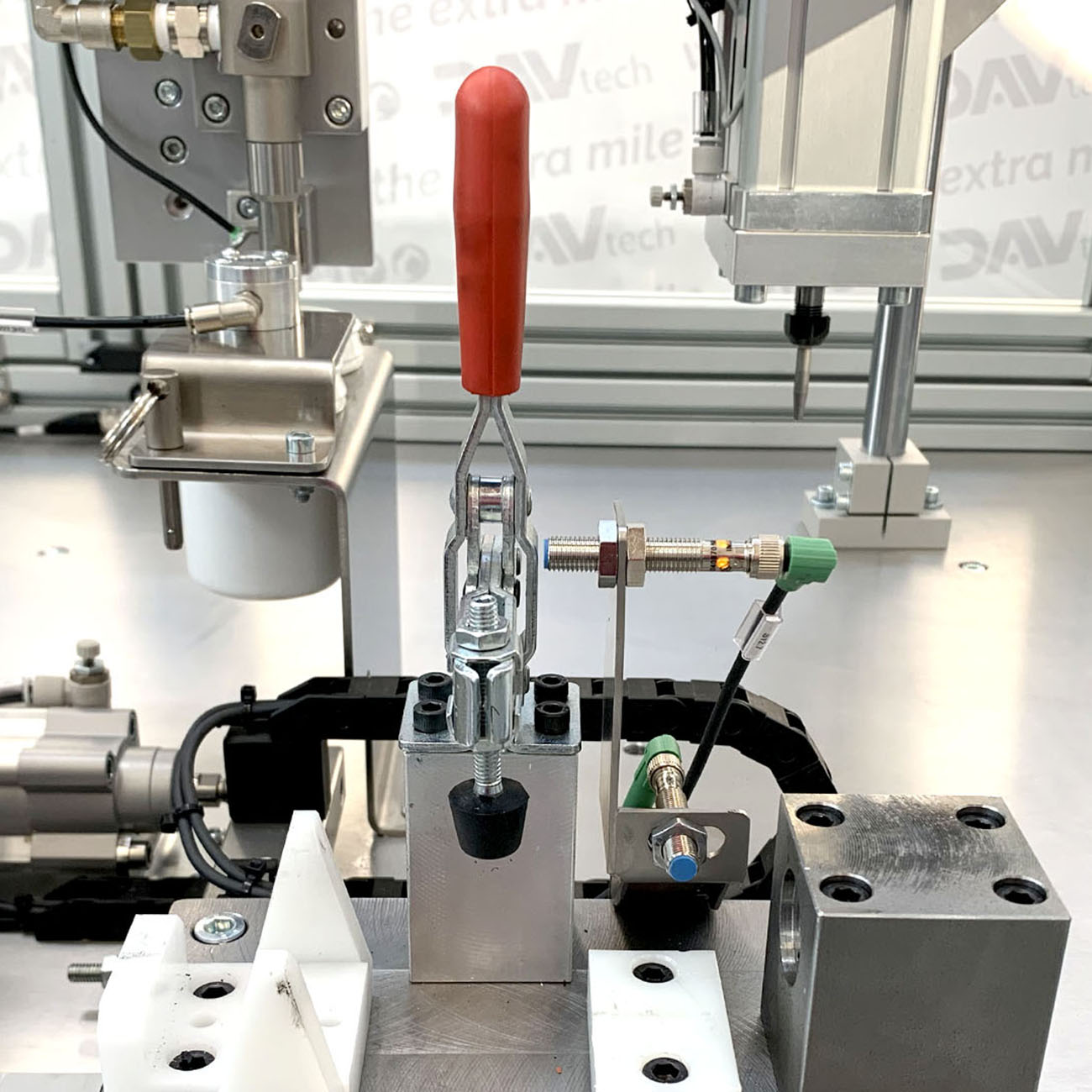

Sensorized Fixture

Equipped with sensors to control the closure and presence of the component, ensuring correct positioning and effective sealing.

Volumetric Dispensing with PCP Progressive Cavity Pump

The pump ensures precise and consistent sealant dispensing, insensitive to temperature and pressure variations, for uniform and reliable sealing.

Quality Control and Monitoring

Quality Control with Laser Sensor

Used to verify the correctness of dispensing and ensure that the sealant is applied in the right amount and position.

Automatic Pressing

The system automatically adjusts the pressing force and height to ensure uniform pressure and correct sealing.

Marking and Process Management

Automatic Bulining

Applied to mark components and confirm their compliance, facilitating tracking and quality verification.

Minimum Level Control Feed Cartridges

Monitor the sealant level, ensuring a continuous supply and preventing interruptions in the process.

Interface and Flexibility

HMI Panel with Wizard

Offers an intuitive interface for process management, with wizards that simplify the operation until completion.

Interchangeable Fixtures

Allow you to process different automotive components, increasing the flexibility and efficiency of the system.

02

Results and Benefits

The sealing and assembly system developed fully met the customer’s requirements. The precision in dispensing and the ability to handle external variables such as temperature and pressure have ensured high and consistent quality. Quality control using laser sensors and automatic marking improved process reliability and facilitated compliance verification. The ease of use of the HMI panel and the flexibility of the interchangeable fixtures have optimized operations, making the system highly effective and adaptable to different production needs.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!