Electrical contact greasing system

Volumetric grease dispensing for electrical contacts.

The operation becomes simple, clean, repeatable and objectifiable.

Volumetric dispensing insensitive to temperature variations.

Quantity independent of the operator and the intensity of pressure of the fixtures.

Poka Yoke logic.

Clean dispensing without residue even after hundreds of cycles.

Compact design and easy to integrate.

Characteristics

• Customized fixtures

• Customized nozzle

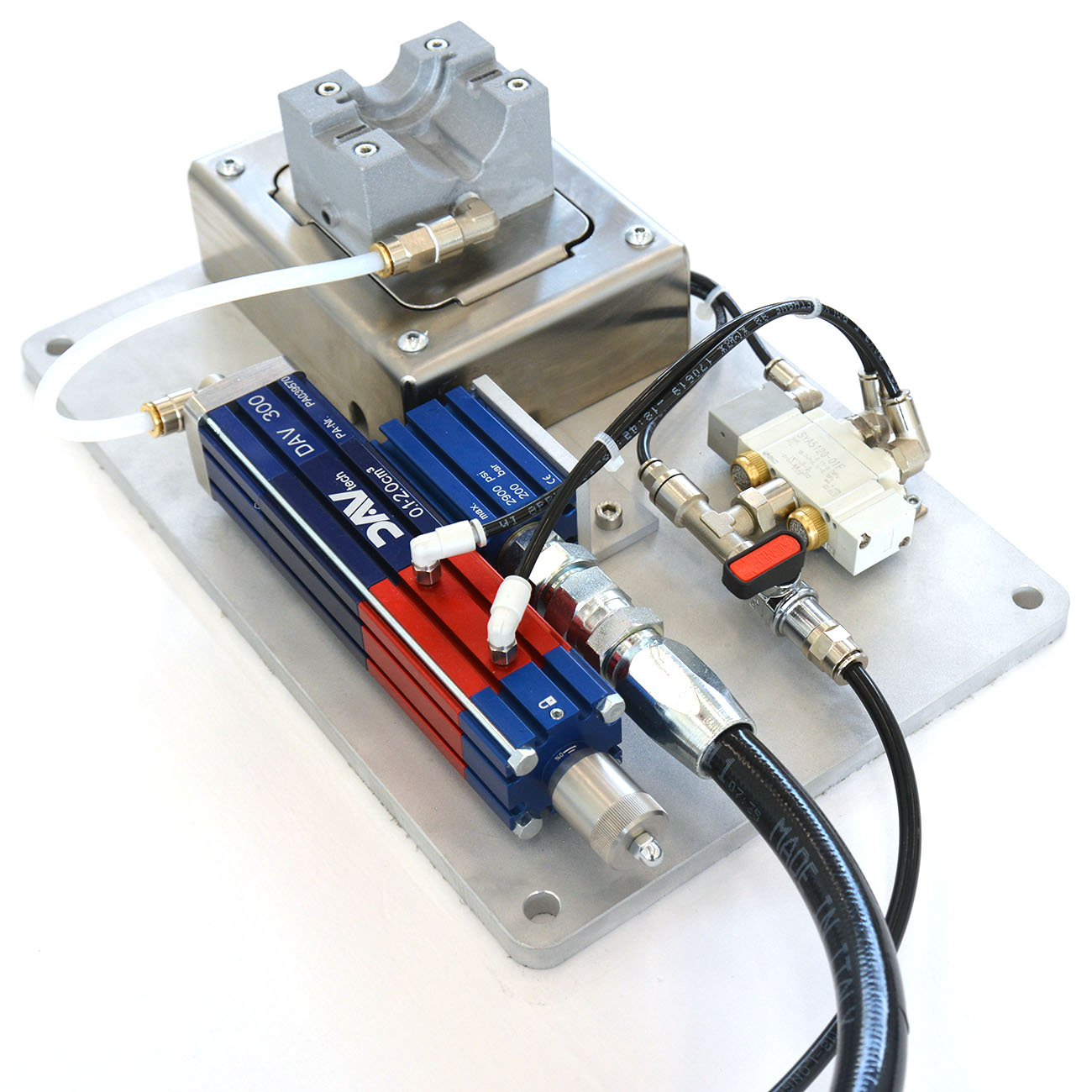

• DAV 300 volumetric valve

• PP1-5 Pressure Plate Pump

CASE STUDY

Volumetric dispensing System for Grease on Electrical Contacts

The customer needed a volumetric dispensing system to apply grease to the electrical contacts, with specific requirements for accuracy and cleanliness. It was essential that the operation was simple, repeatable and objective, maintaining the quality of the dispense regardless of temperature variations and the pressure exerted by the operator. In addition, the system had to ensure clean dispensing without residue even after hundreds of cycles and have a compact design for easy integration into the existing process.

01

Solution Provided

We have designed and built a volumetric dispensing station that has satisfied all customer needs:

Precise and Consistent Dispensing

DAV 300 Volumetric Valve

Used to ensure precise and repeatable volumetric dispensing, insensitive to temperature variations and independent of the intensity of pressure exerted by the operator.

PP1-5 Pressure Plate Pump

Chosen for its ability to dispense grease cleanly and without residue, even after numerous cycles, ensuring a long life and reliability of the system.

Design and Functionality

Customized Fixtures

Custom-designed to fit perfectly to the electrical contacts, ensuring correct and stable positioning of the component during dispensing.

Custom Nozzle

Specifically developed to apply grease precisely and evenly, minimizing residue formation and ensuring a clean application.

Poka Yoke Logic and Ease of Integration

Poka Yoke Logic

Implemented to ensure that the dispensing process is always correct and that any errors are avoided.

Compact design

The station is designed to be easily integrated into your existing system, optimizing space and improving operational efficiency.

02

Results and Benefits

The volumetric dispensing system developed fully met the customer’s needs. Dispensing was simple, clean and repeatable, with precise and residue-free dispensing. The ability to maintain consistent performance regardless of temperature changes and operator pressure ensured consistent product quality. The compact design and ease of integration have optimized space and improved the efficiency of the production process.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!