Castrol Optitemp HT 1 LF volumetric greasing system

Castrol Optitemp HT 1 LF volumetric greasing.

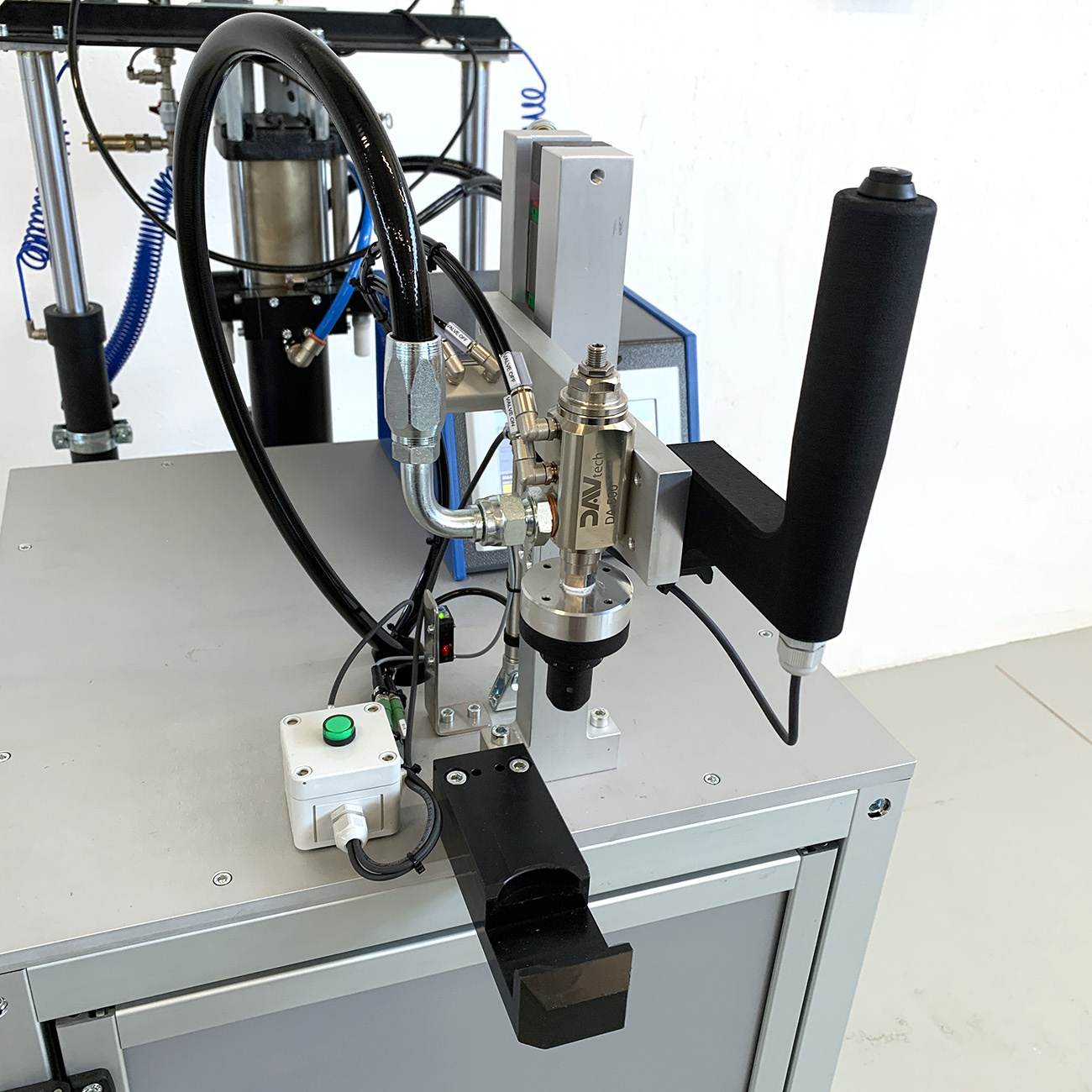

Ergonomic semi-automatic system for volumetric greasing on automotive components.

Characteristics

• Customized and interchangeable fixtures and nozzle allow the dispensing of various sizes.

• Station equipped with component presence sensor and valve detection sensor in dispensing position.

• Ergonomic handle with start button.

• Automated locking of the valve in the dispensing position with automatic release after dispensing.

• Controller for complete management of greasing programs.

• Volumetric dispensing system by GP gear pump.

• End of cycle and dispensing result by light signal.

CASE STUDY

Volumetric Greasing System for Castrol Optitemp HT 1 LF

An automotive parts manufacturer needed a semi-automated volumetric greasing solution with Castrol Optitemp HT 1 LF. The goal was to improve the efficiency and accuracy of the greasing process, ensuring versatility for different component sizes and accurate control of the batching process.

01

Solution Provided

To meet these needs, we have designed and implemented an advanced and ergonomic volumetric greasing system, which integrates the following features and technologies:

Components and Design:

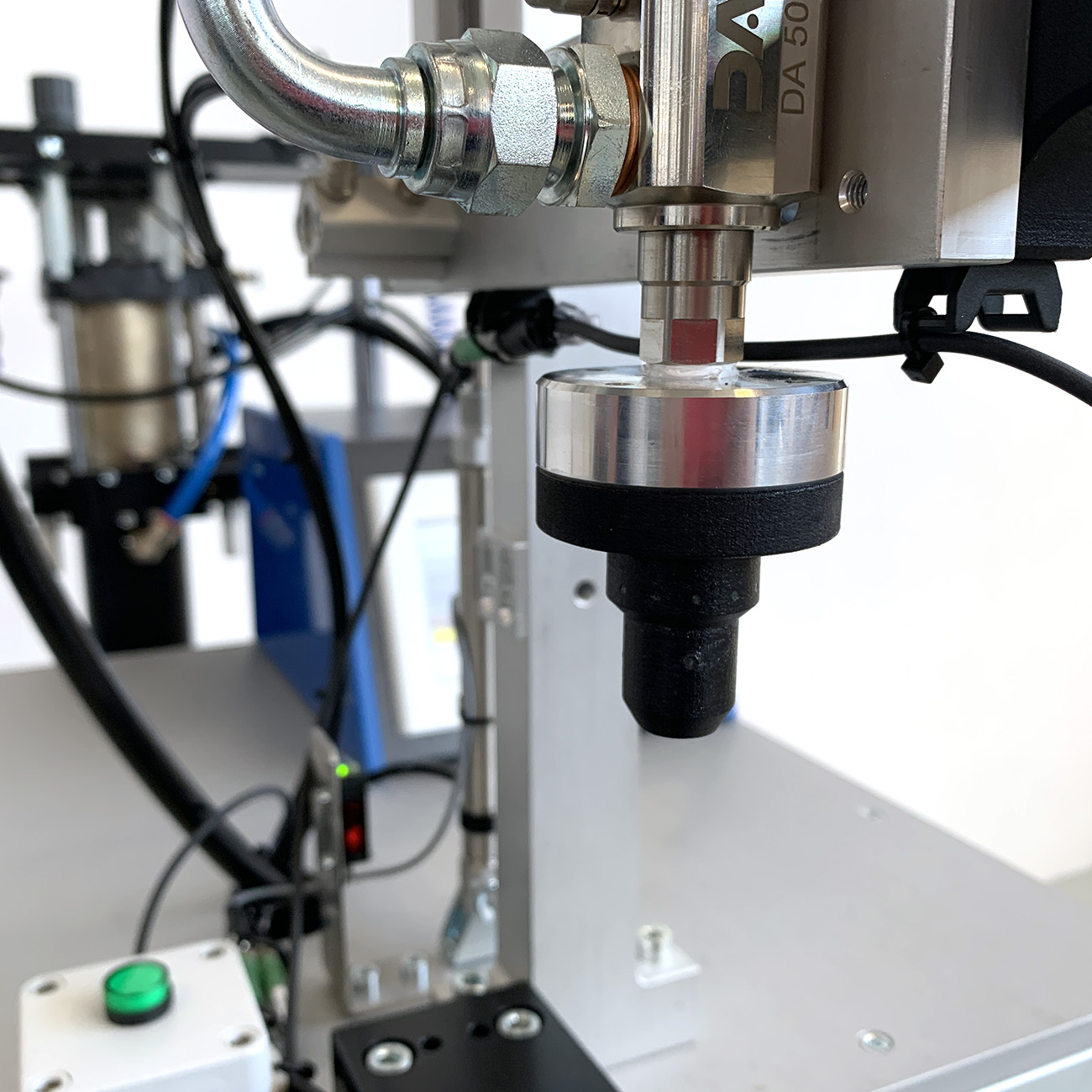

Custom Fixtures and Nozzle

The fixtures and nozzle have been custom designed and are interchangeable, allowing dispensing on components of various sizes. This ensures flexibility and adaptability of the system to different applications.

Presence and Detection Sensors

The system is equipped with sensors to detect the presence of the component and the correct position of the valve during dispensing, ensuring accuracy and reducing the risk of errors.

Ergonomic Handle

The station is equipped with an ergonomic handle that includes a start button, facilitating operation and improving operator comfort.

Advanced Features

Automated Valve Lock

The dispensing valve automatically locks into place during the greasing process and is automatically released when dispensing is complete, improving efficiency and accuracy.

Complete Controller

An advanced controller manages all the greasing programs, allowing easy customization and complete management of the dispensing parameters.

Volumetric Dispensing System

The GP gear pump is used for volumetric dispensing of grease, ensuring uniform and precise distribution.

Light Signaling

At the end of the dispensing cycle, the system provides a light signal to confirm the completion of the process and the success of dispensing.

02

Results and Benefits

The designed volumetric greasing system met the customer’s needs, significantly improving the efficiency and precision of the greasing process. The possibility of using interchangeable fixtures and nozzles has allowed great versatility in the management of components of different sizes. Presence sensors and automated valve management have reduced errors and optimized operation time. In addition, the light signaling made it easier to verify the completion of the dispensing cycle.

In summary, the solution provided has optimised the greasing process for Castrol Optitemp HT 1 LF, ensuring precise and reliable management of operations, and improving the overall efficiency of automotive parts production.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!