Volumetric greasing system KLUBERTEMP GR M30

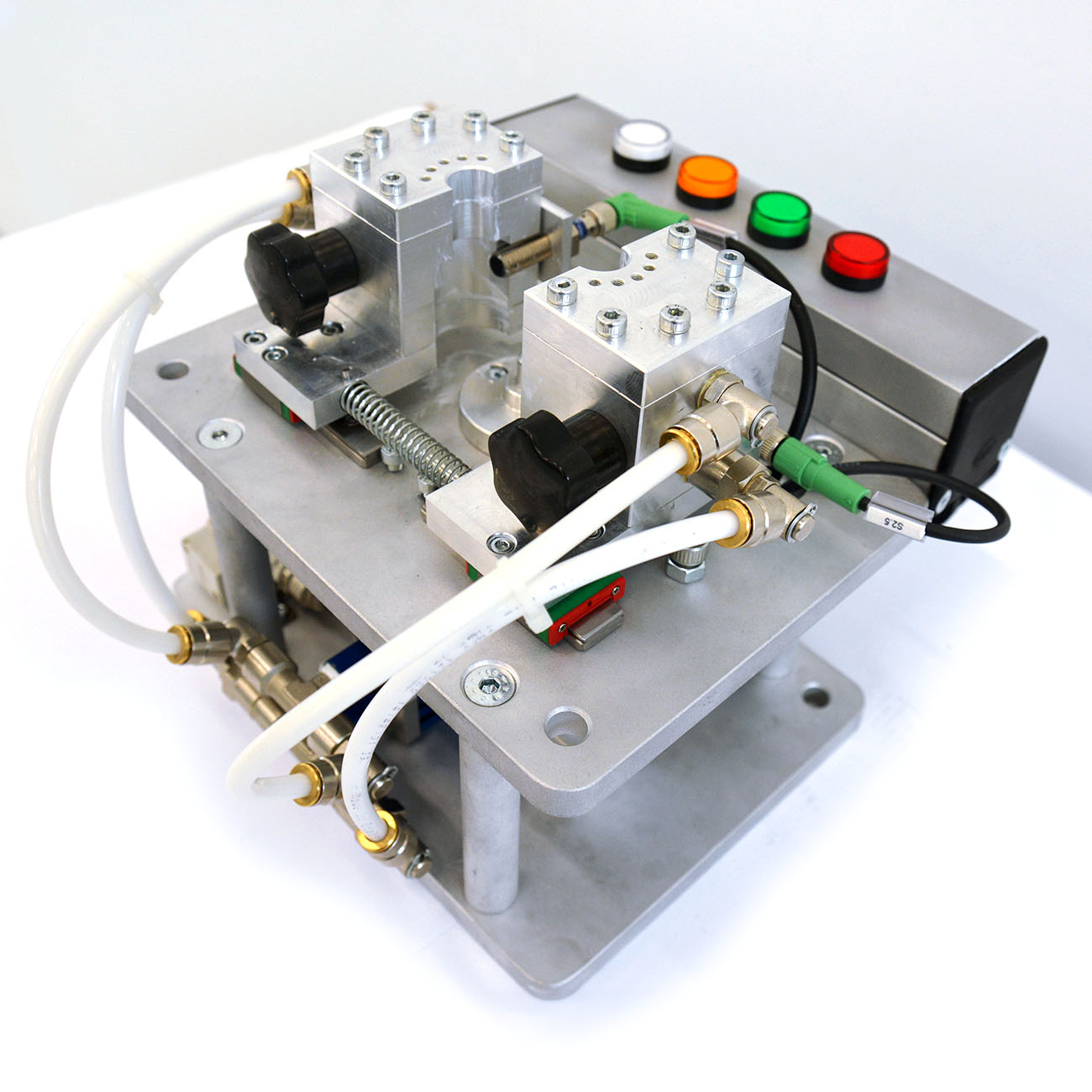

Manual volumetric greasing station on lip seal.

Compact and ergonomic station for multi-point volumetric Grease dispensing. Objectification of the dispensing, control of the presence of the piece and position of the applicator.

Characteristics

CASE STUDY

Manual Volumetric Greasing Station on Lip Seal

A company specializing in the production of mechanical components required a volumetric greasing solution that was both compact and ergonomic. The system needed to be able to handle multi-point dispensing of grease on lip seals, ensuring precise application and complete control of dispensing, part presence and applicator position.

01

Solution Provided

To meet the customer’s needs, we have designed and implemented a manual volumetric greasing station, specifically designed for lip seals. The station has been designed to offer simple and intuitive operation, while maintaining high standards of precision and control.

Main Components

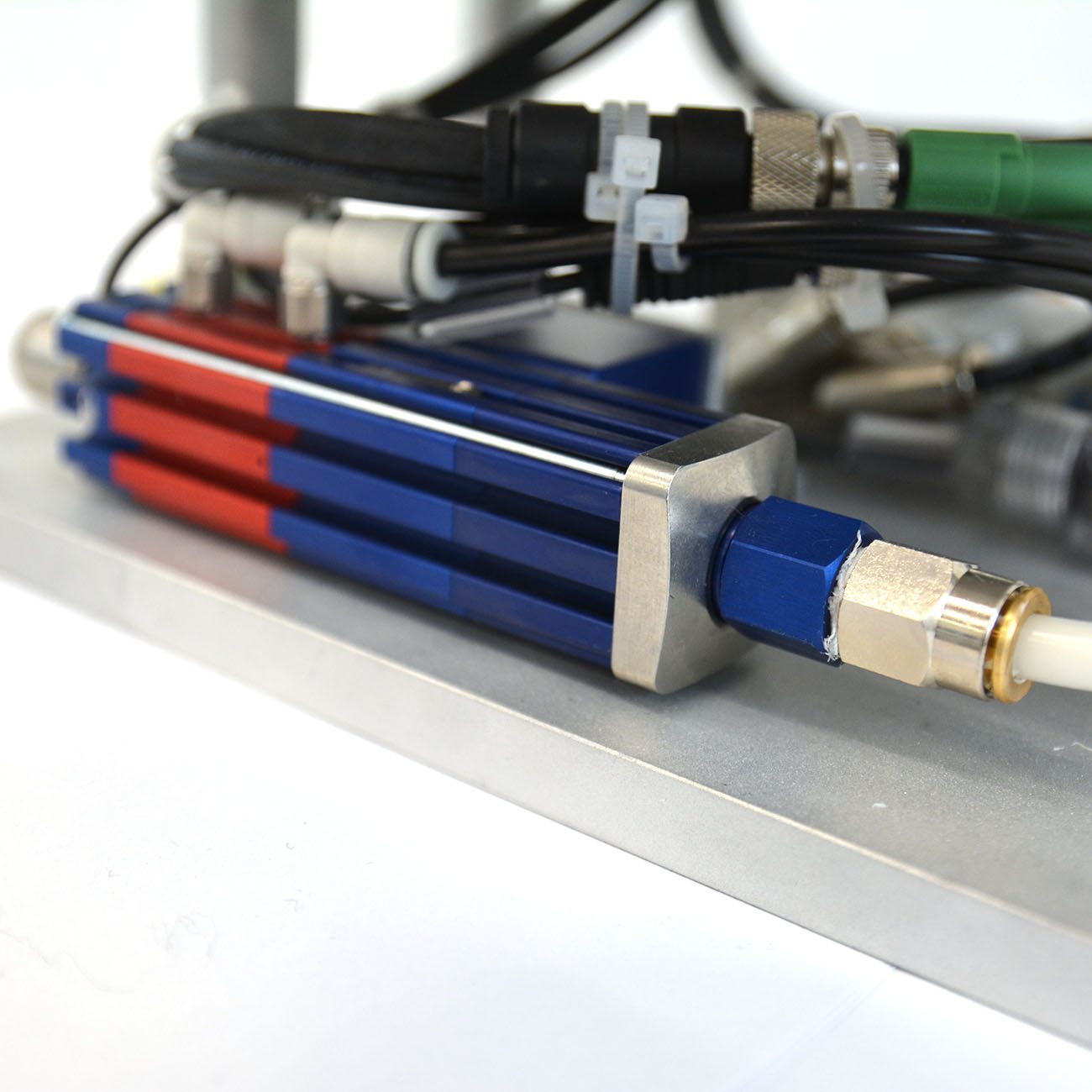

DAV 300 Volumetric Valve

The DAV 300 volumetric valve was chosen to ensure precise and reliable dispensing of multi-point grease.

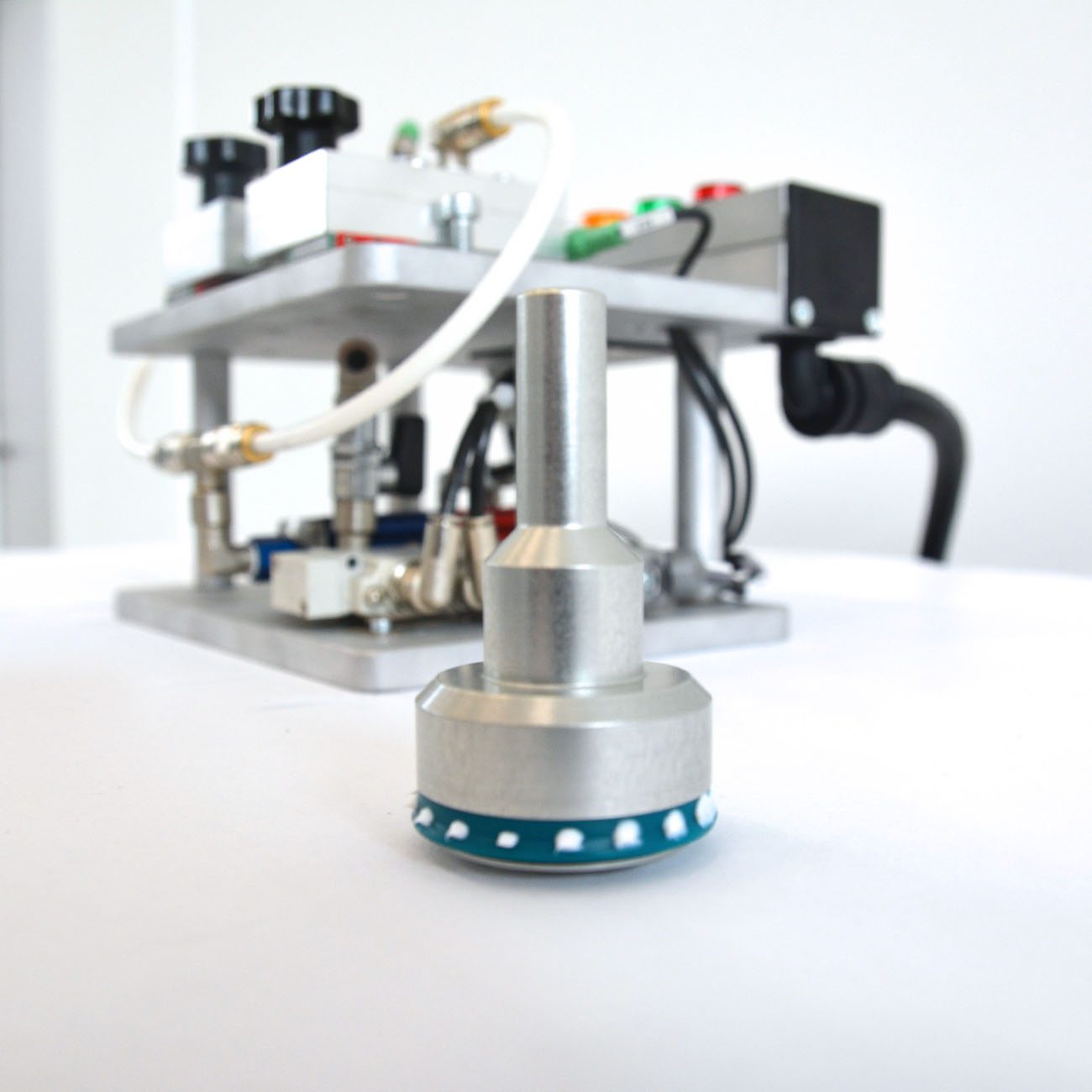

Custom Nozzle

A custom nozzle has been developed to optimize grease application on lip seals, ensuring adequate coverage and accuracy.

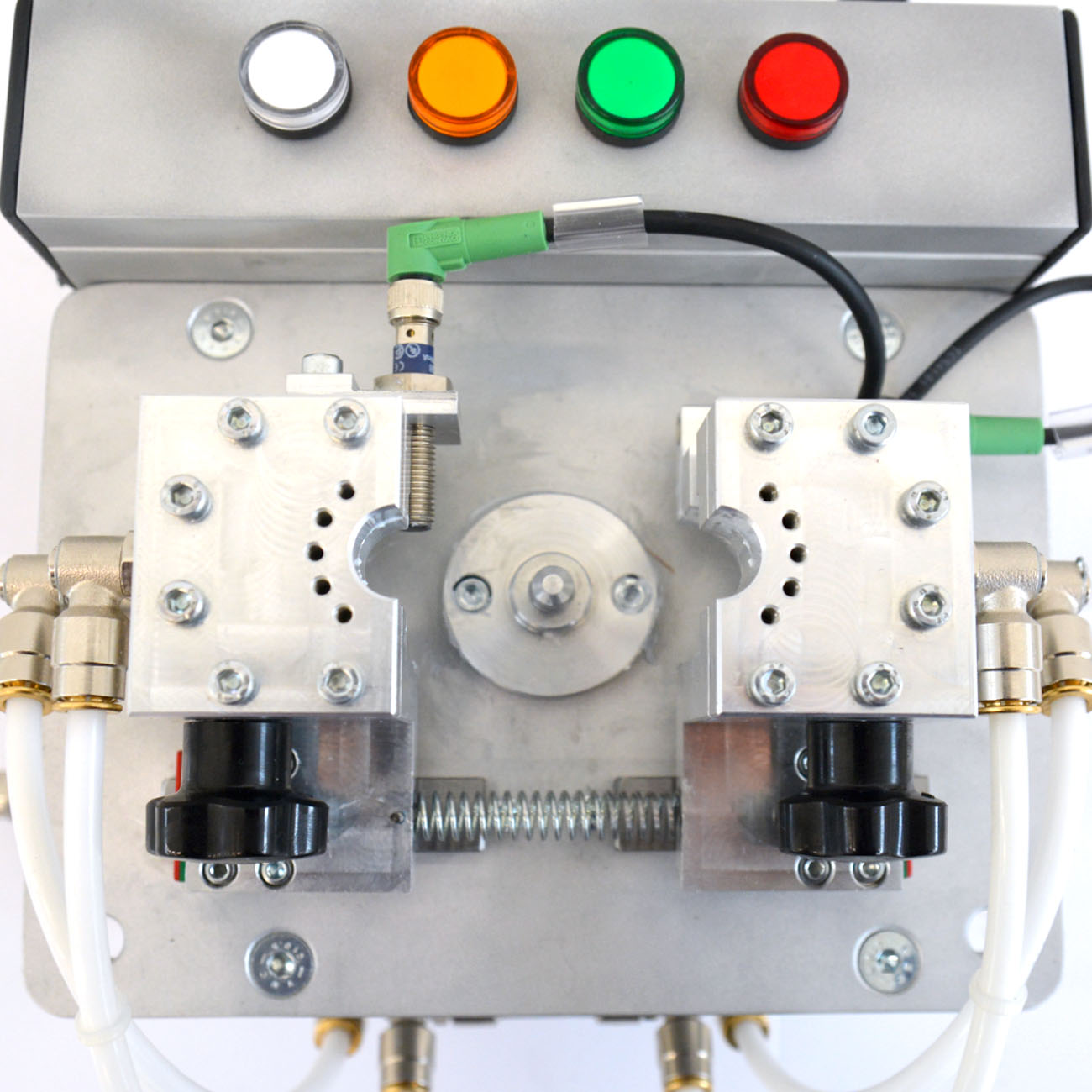

Advanced Features

Integrated Sensors

Advanced sensors have been integrated to monitor part presence and correct applicator position, ensuring that dispensing only occurs when all conditions are met.

Pneumatic Control

The pneumatic system has been implemented to precisely manage the applicator drive and ensure uniform dispensing.

Design and Ergonomics

Compact and Ergonomic Station

The station is designed to be compact and ergonomic, making it easy for operators to access and use, while reducing footprint and improving operational efficiency.

02

Results and Benefits

The volumetric greasing station fully met the customer’s expectations, offering a compact and ergonomic solution for grease dispensing on lip seals. The integrated sensors and pneumatic system ensured accurate process control, improving application quality and reducing waste. The customization of the nozzle and the precision of the DAV 300 volumetric valve ensured effective and reliable dispensing.

In summary, our solution allowed the customer to achieve a precise and controlled greasing process, optimizing operations and improving overall production efficiency.

Need more information?

If you need further information or have specific questions about our industrial dispensing solutions, don’t hesitate to contact us. Our team of experts is ready to assist you and provide all the answers you need!